- Replacement of throttle body with motor assembly

- Cleaning the deposits from the throttle body with motor assembly

- Replacement of camshaft (for intake or exhaust camshaft)

- Replacement of camshaft timing gear assembly

- Replacement of camshaft timing exhaust gear assembly

- Replacement of fuel injector assembly (for port injection)

- Replacement of fuel injector assembly (for direct injection)

- Replacement of fuel pump assembly (for high pressure side)

- Replacement of ignition coil assembly

- Air leaks from intake system

- Gas leak from exhaust system is repaired

- Replacement of knock control sensor

| Last Modified: 11-20-2023 | 6.11:8.1.0 | Doc ID: RM100000001EB2L |

| Model Year Start: 2019 | Model: Camry | Prod Date Range: [08/2018 - 10/2020] |

| Title: 2GR-FKS (ENGINE MECHANICAL): CYLINDER HEAD GASKET: REMOVAL; 2019 - 2020 MY Camry [08/2018 - 10/2020] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during cylinder head gasket removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane departure alert system (w/ Steering Control) |

|

|

Pre-collision system |

|||

|

Intelligent clearance sonar system*1 |

|||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

||

|

Panoramic view monitor system |

|||

|

Replacement of ECM |

Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

||

|

|

Inspection After Repair |

|

|

|

Replacement of automatic transaxle assembly |

|

|

|

|

Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) |

|

||

|

Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) |

|

||

|

Replacement of ECM |

Code registration (Smart key System (for Start Function)) |

|

|

|

Replacement of automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly. |

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Rear television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

Replacement of front bumper assembly |

Front television camera view adjustment |

Panoramic view monitor system |

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

|

||

|

Front wheel alignment adjustment |

Perform system variant learning and acceleration sensor zero point calibration. |

|

PROCEDURE

1. INSTALL ENGINE ASSEMBLY TO ENGINE STAND

2. REMOVE ENGINE HANGERS

3. REMOVE KNOCK CONTROL SENSOR

4. REMOVE IGNITION COIL ASSEMBLY

5. REMOVE VACUUM PUMP ASSEMBLY

6. REMOVE V-RIBBED BELT

7. REMOVE GENERATOR ASSEMBLY

8. REMOVE COMPRESSOR ASSEMBLY WITH MAGNETIC CLUTCH

9. REMOVE NO. 2 IDLER PULLEY SUB-ASSEMBLY

10. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

11. REMOVE WATER PUMP PULLEY

12. REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

13. REMOVE WIRE HARNESS CLAMP BRACKET

14. REMOVE WATER FILLER BRACKET

15. REMOVE CRANKSHAFT PULLEY

16. REMOVE FRONT NO. 1 ENGINE MOUNTING BRACKET LH

17. DISCONNECT WATER BY-PASS HOSE

18. REMOVE WATER INLET WITH THERMOSTAT SUB-ASSEMBLY

19. REMOVE CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Intake Side of Bank 1)

20. REMOVE CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Exhaust Side of Bank 1)

21. REMOVE CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Exhaust Side of Bank 2)

22. REMOVE CAMSHAFT TIMING OIL CONTROL SOLENOID ASSEMBLY (for Intake Side of Bank 2)

23. REMOVE VVT SENSOR (for Intake Side of Bank 1)

24. REMOVE VVT SENSOR (for Exhaust Side of Bank 1)

25. REMOVE VVT SENSOR (for Intake Side of Bank 2)

26. REMOVE VVT SENSOR (for Exhaust Side of Bank 2)

27. REMOVE CRANKSHAFT POSITION SENSOR PROTECTOR

28. REMOVE SENSOR WIRE

29. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

30. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY LH

31. REMOVE SPARK PLUG TUBE GASKET

32. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY

33. REMOVE OIL STRAINER SUB-ASSEMBLY

34. REMOVE OIL PAN SUB-ASSEMBLY

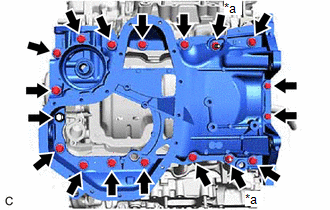

|

(a) Remove the 16 bolts and 2 nuts from the oil pan sub-assembly. NOTICE: Make sure to clean the bolts and stud bolts and check the threads for cracks or other damage. |

|

|

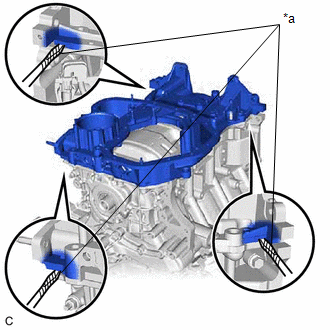

(b) Remove the oil pan sub-assembly by prying between the oil pan sub-assembly and timing chain cover assembly or cylinder block sub-assembly with a screwdriver wrapped with protective tape. NOTICE: Be careful not to damage the contact surfaces of the cylinder block sub-assembly, timing chain cover assembly and oil pan sub-assembly. |

|

|

(c) Remove the 2 oil pan gaskets from the timing chain cover assembly. |

|

35. REMOVE TIMING CHAIN COVER ASSEMBLY

36. REMOVE TIMING CHAIN CASE OIL SEAL

37. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

38. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

39. REMOVE CHAIN TENSIONER SLIPPER

40. REMOVE CHAIN SUB-ASSEMBLY

41. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY, CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY AND NO. 2 CHAIN SUB-ASSEMBLY (for Bank 1)

42. REMOVE NO. 2 CHAIN TENSIONER ASSEMBLY

43. REMOVE CAMSHAFT BEARING CAP (for Bank 1)

44. REMOVE CAMSHAFT

45. REMOVE NO. 2 CAMSHAFT

46. REMOVE CAMSHAFT HOUSING SUB-ASSEMBLY

47. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY, CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY AND NO. 2 CHAIN SUB-ASSEMBLY (for Bank 2)

48. REMOVE NO. 3 CHAIN TENSIONER ASSEMBLY

49. REMOVE CAMSHAFT BEARING CAP (for Bank 2)

50. REMOVE NO. 3 CAMSHAFT SUB-ASSEMBLY

51. REMOVE NO. 4 CAMSHAFT SUB-ASSEMBLY

52. REMOVE CAMSHAFT HOUSING SUB-ASSEMBLY LH

53. REMOVE SENSOR WIRE

54. REMOVE NO. 1 CHAIN VIBRATION DAMPER

55. REMOVE NO. 2 CHAIN VIBRATION DAMPER

56. REMOVE NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

57. REMOVE VALVE LASH ADJUSTER ASSEMBLY

58. REMOVE VALVE STEM CAP

59. REMOVE WATER OUTLET

60. REMOVE CYLINDER HEAD SUB-ASSEMBLY

61. REMOVE CYLINDER HEAD GASKET

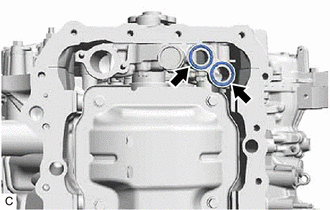

(a) Remove the cylinder head gasket from the cylinder block sub-assembly.

62. REMOVE CYLINDER HEAD LH

63. REMOVE NO. 2 CYLINDER HEAD GASKET

(a) Remove the No. 2 cylinder head gasket from the cylinder block sub-assembly.

64. INSPECT CYLINDER HEAD SET BOLT

|

|

|

![2018 - 2020 MY Camry [03/2017 - 10/2020]; PRE-COLLISION: PRE-COLLISION SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)