- Reset memory*2

- Transfer transaxle compensation code

- Perform road test to allow ECM to learn

| Last Modified: 11-20-2023 | 6.11:8.1.0 | Doc ID: RM100000001E7WD |

| Model Year Start: 2019 | Model: Camry | Prod Date Range: [08/2018 - 09/2019] |

| Title: UA80E (AUTOMATIC TRANSMISSION / TRANSAXLE): OIL COOLER: REMOVAL; 2019 MY Camry [08/2018 - 09/2019] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during transmission oil cooler removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane departure alert system (w/ Steering Control) |

|

|

Pre-collision system |

|||

|

Intelligent clearance sonar system*1 |

|||

|

Memorize steering angle neutral point |

Parking assist monitor system |

||

|

Panoramic view monitor system |

|||

|

Replacement of ECM |

Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

||

|

Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) |

|

|

|

|

Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) |

|

||

|

Replacement of ECM |

Code registration (Smart key System (for Start Function)) |

|

|

|

Replacement of automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly. |

PROCEDURE

1. REMOVE BATTERY

2. REMOVE ECM

3. REMOVE BATTERY CLAMP SUB-ASSEMBLY

4. REMOVE FRONT WHEEL LH

5. REMOVE FRONT WHEEL OPENING EXTENSION PAD LH

6. REMOVE FRONT WHEEL OPENING EXTENSION PAD RH

7. REMOVE NO. 1 ENGINE UNDER COVER

8. REMOVE REAR ENGINE UNDER COVER LH

9. REMOVE FRONT FENDER APRON SEAL LH

10. DRAIN ENGINE COOLANT

11. DRAIN AUTOMATIC TRANSAXLE FLUID

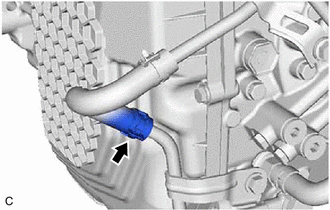

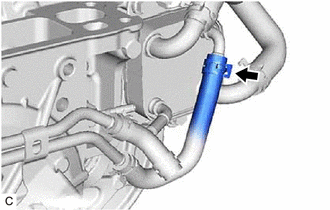

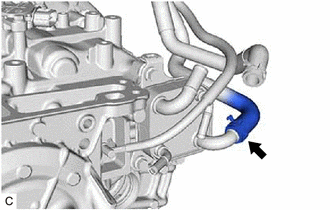

12. DISCONNECT OUTLET NO. 1 OIL COOLER HOSE

|

(a) Slide the clip and disconnect the outlet No. 1 oil cooler hose from the oil cooler union sub-assembly. HINT: Use a container to catch any automatic transaxle fluid which flows out of the outlet No. 1 oil cooler hose and oil cooler union sub-assembly. |

|

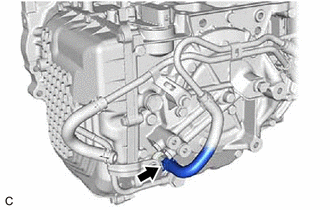

13. DISCONNECT INLET NO. 1 OIL COOLER HOSE

|

(a) Slide the clip and disconnect the inlet No. 1 oil cooler hose from the No. 1 oil cooler outlet tube sub-assembly. HINT: Use a container to catch any automatic transaxle fluid which flows out of the inlet No. 1 oil cooler hose and No. 1 oil cooler outlet tube sub-assembly. |

|

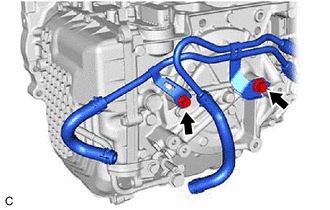

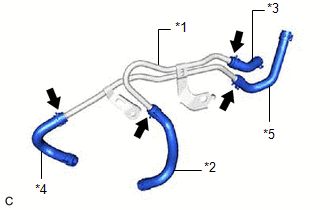

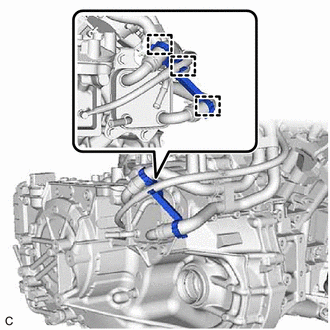

14. REMOVE NO. 1 OIL COOLER TUBE SUB-ASSEMBLY WITHOUT HOSE

|

(a) Remove the 2 bolts to disconnect the No. 1 oil cooler tube sub-assembly without hose from the automatic transaxle case sub-assembly. |

|

|

(b) Slide the clip and disconnect the inlet No. 2 oil cooler hose from the transmission oil cooler. HINT: Use a container to catch any automatic transaxle fluid which flows out of the inlet No. 2 oil cooler hose and transmission oil cooler. |

|

|

(c) Slide the clip and disconnect the outlet No. 2 oil cooler hose to remove the No. 1 oil cooler tube sub-assembly without hose from the transmission oil cooler. HINT: Use a container to catch any automatic transaxle fluid which flows out of the outlet No. 2 oil cooler hose and transmission oil cooler. |

|

|

(d) Slide the 4 clips and remove the inlet No. 1 oil cooler hose, inlet No. 2 oil cooler hose, outlet No. 1 oil cooler hose and outlet No. 2 oil cooler hose from the No. 1 oil cooler tube sub-assembly without hose. |

|

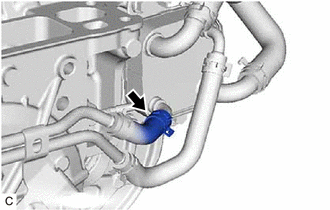

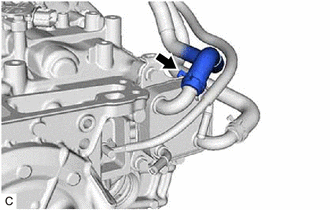

15. DISCONNECT NO. 1 WATER BY-PASS HOSE

|

(a) Disengage the 3 clamps to remove the transmission breather clamp. |

|

|

(b) Slide the clip and disconnect the No. 1 water by-pass hose from the transmission oil cooler. HINT: Use a container to catch any coolant which flows out of the No. 1 water by-pass hose and transmission oil cooler. |

|

16. DISCONNECT WATER BY-PASS HOSE ASSEMBLY

|

(a) Slide the clip and disconnect the water by-pass hose assembly from the transmission oil cooler. HINT: Use a container to catch any coolant which flows out of the water by-pass hose assembly and transmission oil cooler. |

|

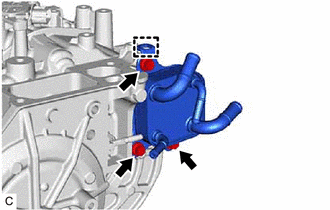

17. REMOVE TRANSMISSION OIL COOLER

|

(a) Remove the 3 bolts. |

|

(b) Disengage the hook to remove the transmission oil cooler from the automatic transaxle case sub-assembly.

HINT:

Use a container to catch any coolant and automatic transaxle fluid which flow out of the transmission oil cooler.

|

|

|

![2018 - 2020 MY Camry [03/2017 - 10/2020]; PRE-COLLISION: PRE-COLLISION SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)