- Short to ground

- +B short

| Last Modified: 09-09-2025 | 6.11:8.1.0 | Doc ID: RM1000000015L2F |

| Model Year Start: 2018 | Model: Camry | Prod Date Range: [06/2017 - 10/2020] |

| Title: PARK ASSIST / MONITORING: INTELLIGENT CLEARANCE SONAR SYSTEM: U0232,U0233; Lost Communication with Blind Spot Monitor Slave Module; 2018 - 2020 MY Camry [06/2017 - 10/2020] | ||

|

DTC |

U0232 |

Lost Communication with Blind Spot Monitor Slave Module |

|

DTC |

U0233 |

Lost Communication with Blind Spot Monitor Master Module |

DESCRIPTION

This DTC is stored when the blind spot monitor sensor LH judges that there is a communication problem with the blind spot monitor sensor RH.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

U0232 |

Lost Communication with Blind Spot Monitor Slave Module |

The clearance warning ECU assembly cannot receive signals from the blind spot monitor sensor (slave) |

|

|

U0233 |

Lost Communication with Blind Spot Monitor Master Module |

The clearance warning ECU assembly cannot receive signals from the blind spot monitor sensor (master) |

|

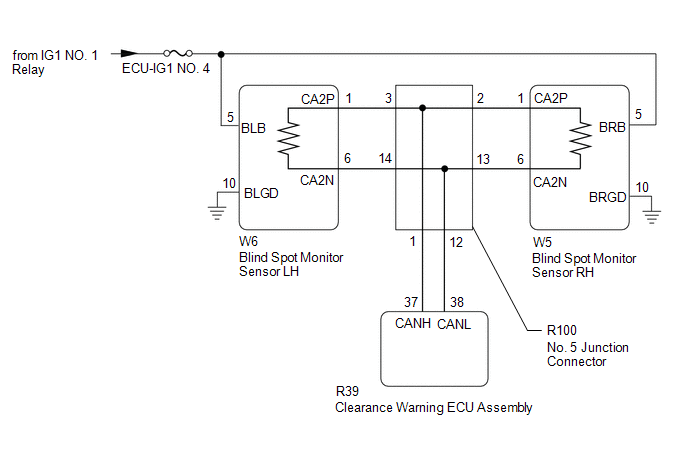

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

- Before measuring the resistance of the CAN bus, turn the engine switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

- After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

HINT:

- Operating the engine switch, any other switches or a door triggers related ECU and sensor communication on the CAN. This communication will cause the resistance value to change.

- Even after DTCs are cleared, if a DTC is stored again after driving the vehicle for a while, the malfunction may be occurring due to vibration of the vehicle. In such a case, wiggling the ECUs or wire harness while performing the inspection below may help determine the cause of the malfunction.

PROCEDURE

PROCEDURE

|

1. |

CHECK DTC |

(a) Check for DTCs.

Body Electrical > Advanced Parking Guidance/ICS/Intuitive P/A > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC U0232 is only output |

A |

|

DTC U0233 is only output |

B |

|

DTC U0232 and U0233 are output |

C |

| B |

|

| C |

|

|

|

2. |

CHECK CAN BUS MAIN WIRE |

(a) Disconnect the cable from the negative (-) battery terminal.

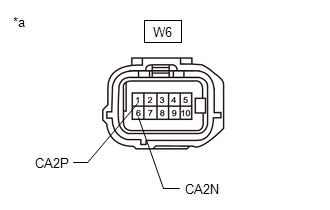

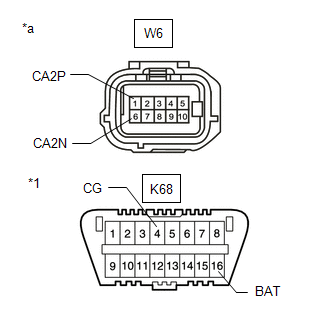

(b) Disconnect the W6 blind spot monitor sensor LH connector.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR LH - No. 5 JUNCTION CONNECTOR) |

|

|

3. |

CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR LH - BODY GROUND) |

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR LH - No. 5 JUNCTION CONNECTOR) |

|

|

4. |

CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR LH POWER SOURCE) |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

5. |

CHECK CAN BUS MAIN WIRE |

(a) Disconnect the cable from the negative (-) battery terminal.

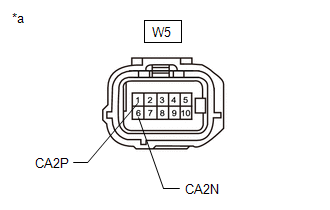

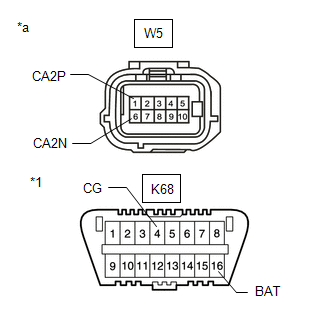

(b) Disconnect the W5 blind spot monitor sensor RH connector.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR RH - No. 5 JUNCTION CONNECTOR) |

|

|

6. |

CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR RH - BODY GROUND) |

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR LH - No. 5 JUNCTION CONNECTOR) |

|

|

7. |

CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR RH POWER SOURCE) |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

8. |

CHECK CAN BUS MAIN WIRE (BLIND SPOT MONITOR SENSOR LH) |

(a) Turn the engine switch off.

(b) Disconnect the cable from the negative (-) battery terminal.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

Open circuit in CAN main bus lines |

B |

|

Short circuit between bus lines |

C |

|

|

D |

| B |

|

| C |

|

| D |

|

|

|

9. |

CONFIRM CAN BUS WIRE (CLEARANCE WARNING ECU ASSEMBLY) |

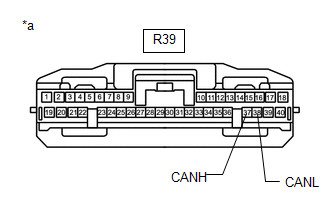

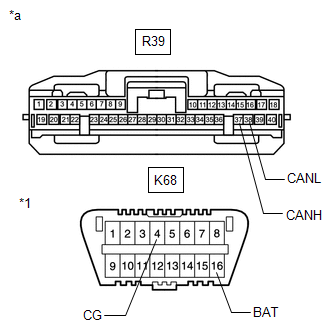

(a) Disconnect the R39 clearance warning ECU assembly connector.

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |

|

REPAIR OR REPLACE CAN BUS WIRE (CLEARANCE WARNING ECU ASSEMBLY - No. 5 JUNCTION CONNECTOR) |

|

|

10. |

CHECK DTC |

(a) Clear the DTCs.

Body Electrical > Advanced Parking Guidance/ICS/Intuitive P/A > Clear DTCs

(b) Check for DTCs.

Body Electrical > Advanced Parking Guidance/ICS/Intuitive P/A > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC U0232 and U0233 are output |

A |

|

DTC U0232 and U0233 are not output |

B |

| A |

|

| B |

|

USE SIMULATION METHOD TO CHECK |

|

11. |

CHECK FOR OPEN IN CAN BUS WIRE (No. 5 JUNCTION CONNECTOR) |

|

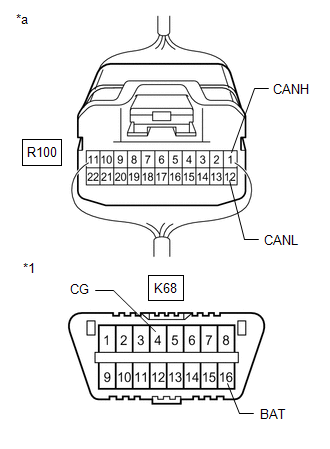

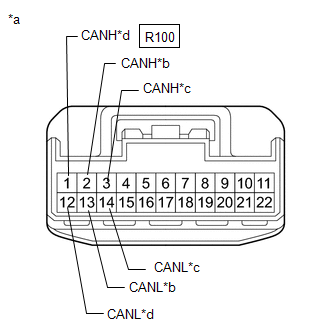

(a) Disconnect the R100 No. 5 junction connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

R100-3 (CANH) - R100-14(CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

|

R100-2 (CANH) - R100-13 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

|

R100-1 (CANH) - R100-12(CANL) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (to blind spot monitor sensor RH CAN main wire) |

B |

|

NG (to blind spot monitor sensor LH CAN main wire) |

C |

|

NG (to clearance warning ECU assembly CAN wire) |

D |

| A |

|

REPLACE No. 5 JUNCTION CONNECTOR |

| B |

|

| C |

|

| D |

|

|

12. |

CHECK FOR OPEN IN CAN BUS MAIN WIRE (BLIND SPOT MONITOR SENSOR RH) |

(a) Reconnect the R100 No. 5 junction connector.

|

(b) Disconnect the W5 blind spot monitor sensor RH connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

W5-1 (CA2P) - W5-6 (CA2N) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR RH - No. 5 JUNCTION CONNECTOR) |

|

13. |

CHECK FOR OPEN IN CAN BUS MAIN WIRE (BLIND SPOT MONITOR SENSOR LH) |

(a) Reconnect the R100 No. 5 junction connector.

|

(b) Disconnect the W6 blind spot monitor sensor LH connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

W6-1 (CA2P) -W6-6 (CA2N) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR LH - No. 5 JUNCTION CONNECTOR) |

|

14. |

CHECK FOR OPEN IN CAN BUS WIRE (CLEARANCE WARNING ECU ASSEMBLY) |

(a) Reconnect the R100 No. 5 junction connector.

|

(b) Disconnect the R39 clearance warning ECU assembly connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

R39-37(CANH) - R39-38(CANL) |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN BUS WIRE (CLEARANCE WARNING ECU ASSEMBLY - No. 5 JUNCTION CONNECTOR) |

|

15. |

CHECK FOR SHORT IN CAN BUS WIRES (No. 5 JUNCTION CONNECTOR) |

|

(a) Disconnect the R100 No. 5 junction connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

R100-3 (CANH) - R100-14(CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

|

R100-2 (CANH) - R100-13(CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

|

R100-1 (CANH) - R100-12(CANL) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (to blind spot monitor sensor RH CAN main wire) |

B |

|

NG (to blind spot monitor sensor LH CAN main wire) |

C |

|

NG (to clearance warning ECU assembly CAN wire) |

D |

| A |

|

REPLACE No. 5 JUNCTION CONNECTOR |

| B |

|

| C |

|

| D |

|

|

16. |

CHECK FOR SHORT IN CAN BUS WIRES (BLIND SPOT MONITOR SENSOR RH) |

(a) Reconnect the R100 No. 5 junction connector.

|

(b) Disconnect the W5 blind spot monitor sensor RH connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

W5-1 (CA2P) - W5-6 (CA2N) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR RH - No. 5 JUNCTION CONNECTOR) |

|

17. |

CHECK FOR SHORT IN CAN BUS WIRES (BLIND SPOT MONITOR SENSOR LH) |

(a) Reconnect the R100 No. 5 junction connector.

|

(b) Disconnect the W6 blind spot monitor sensor LH connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

W6-1 (CA2P) -W6-6 (CA2N) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR LH - No. 5 JUNCTION CONNECTOR) |

|

18. |

CHECK FOR SHORT IN CAN BUS WIRES (CLEARANCE WARNING ECU ASSEMBLY) |

(a) Reconnect the R100 No. 5 junction connector.

|

(b) Disconnect the R39 clearance warning ECU assembly connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

R39-37(CANH) - R39-38(CANL) |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN BUS WIRE (CLEARANCE WARNING ECU ASSEMBLY - No. 5 JUNCTION CONNECTOR) |

|

19. |

CHECK FOR SHORT IN CAN BUS WIRES (No. 5 JUNCTION CONNECTOR) |

(a) Disconnect the R100 No. 5 junction connector.

(b) Measure the resistance according to the value(s) in the table below.

|

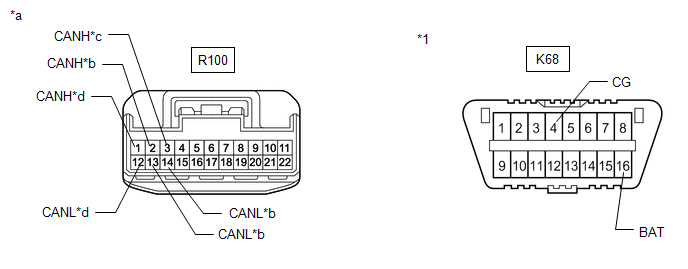

*1 |

DLC3 |

- |

- |

|

*a |

Front view of wire harness connector (to No. 5 Junction Connector) |

*b |

to blind spot monitor sensor RH CAN main wire |

|

*c |

to blind spot monitor sensor LH CAN main wire |

*d |

to clearance warning ECU assembly CAN wire |

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

R100-3 (CANH) - K68-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

R100-14 (CANL) - K68-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

R100-3 (CANH) - K68-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

R100-14 (CANL) - K68-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

R100-1 (CANH) - K68-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

R100-12 (CANL) - K68-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

R100-1 (CANH) - K68-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

R100-12 (CANL) - K68-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

R100-2 (CANH) - K68-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

R100-13 (CANL) - K68-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

R100-2 (CANH) - K68-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

R100-13 (CANL) - K68-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (to blind spot monitor sensor RH CAN main wire) |

B |

|

NG (to blind spot monitor sensor LH CAN main wire) |

C |

|

NG (to clearance warning ECU assembly CAN wire) |

D |

| A |

|

REPLACE No. 5 JUNCTION CONNECTOR |

| B |

|

| C |

|

| D |

|

|

20. |

CHECK FOR SHORT IN CAN BUS WIRES (BLIND SPOT MONITOR SENSOR RH) |

(a) Reconnect the R100 No. 5 junction connector.

(b) Disconnect the W5 blind spot monitor sensor RH connector.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR RH - No. 5 JUNCTION CONNECTOR) |

|

21. |

CHECK FOR SHORT IN CAN BUS WIRES (BLIND SPOT MONITOR SENSOR LH) |

(a) Reconnect the R100 No. 5 junction connector.

(b) Disconnect the W6 blind spot monitor sensor LH connector.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR LH - No. 5 JUNCTION CONNECTOR) |

|

22. |

CHECK FOR SHORT IN CAN BUS WIRES (CLEARANCE WARNING ECU ASSEMBLY) |

(a) Reconnect the R100 No. 5 junction connector.

|

(b) Disconnect the R39 clearance warning ECU assembly connector. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

R39-37 (CANH) - K68-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

R39-38 (CANL) - K68-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

R39-37 (CANH) - K68-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

R39-38 (CANL) - K68-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN BUS WIRE (CLEARANCE WARNING ECU ASSEMBLY - No. 5 JUNCTION CONNECTOR) |

|

|

|

![2018 - 2019 MY Camry [06/2017 - 09/2019]; INTRODUCTION: REPAIR INSTRUCTION: PRECAUTION](/t3Portal/stylegraphics/info.gif)