| Last Modified: 09-09-2025 | 6.11:8.1.0 | Doc ID: RM1000000015IJC |

| Model Year Start: 2018 | Model: Camry | Prod Date Range: [06/2017 - ] |

| Title: 2GR-FKS (FUEL): FUEL INJECTOR (for Port Injection): INSPECTION; 2018 - 2024 MY Camry [06/2017 - ] | ||

INSPECTION

PROCEDURE

PROCEDURE

1. INSPECT FUEL INJECTOR ASSEMBLY

(a) Check the resistance.

|

(1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the fuel injector assembly. |

|

(b) Check the operation.

CAUTION:

Perform the inspection in a well-ventilated area.

Do not perform the inspection near an open flame.

|

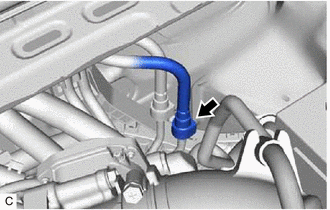

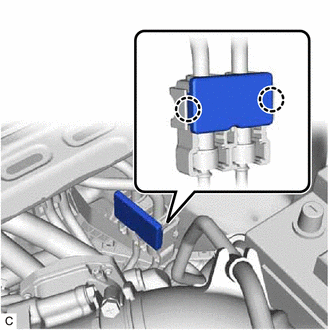

(1) Disengage the 2 claws to remove the No. 2 fuel pipe clamp. |

|

|

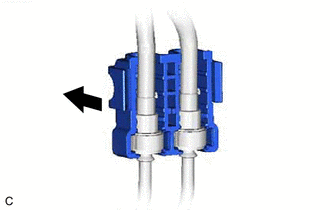

(2) Remove the No. 1 fuel pipe clamp from the fuel tube connector. |

|

|

(3) Disconnect the fuel tube sub-assembly. |

|

|

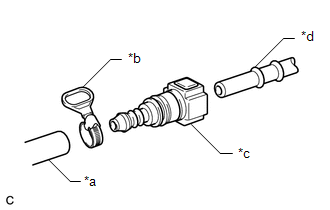

(4) Connect SST (fuel tube connector) to SST (hose) with SST (hose band), and then connect them to the fuel pipe (vehicle side). 09268-31015 09268-41500 09268-41700 95336-08070NOTICE: Make sure the SST (fuel tube connector) O-rings are not damaged and are free of foreign matter as they are used to seal the connections between the fuel tube connector and fuel pipe. |

|

(5) Apply a light coat of gasoline to a new O-ring, and then install the O-ring to the fuel injector assembly.

|

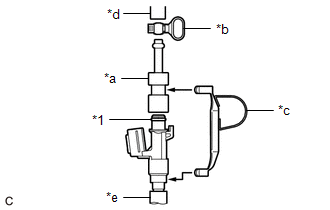

(6) Connect SST (adapter) and SST (hose) to the fuel injector assembly, and hold the fuel injector assembly and union with SST (clamp). 09268-31015 09268-41600 09268-41300 09268-41700 95336-08070 |

|

|

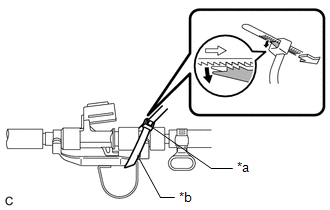

(7) Tie SST (clamp) and SST (adapter) together with SST (tie band) as shown in the illustration. 09268-31015 09268-41800NOTICE:

HINT: When removing SST (tie band), disengage the lock. |

|

(8) Check that SST (clamp) and SST (adapter) cannot be easily separated.

(9) Install a vinyl tube to the fuel injector assembly.

CAUTION:

Install a suitable vinyl tube to the fuel injector assembly to prevent fuel from spraying.

(10) Set the fuel injector assembly into a graduated cylinder.

(11) Connect the Techstream to the DLC3.

(12) Turn the engine switch on (IG).

NOTICE:

Do not start the engine.

(13) Turn the Techstream on.

(14) Enter the following menus: Powertrain / Engine / Active Test / Activate the Circuit Relay.

Powertrain > Engine > Active Test

|

Tester Display |

|---|

|

Activate the Circuit Relay |

|

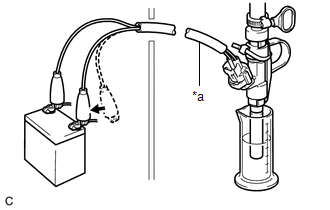

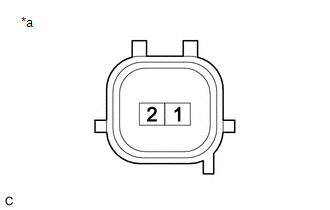

(15) Connect SST (EFI inspection wire I) to the fuel injector assembly and battery for 15 seconds, and measure the injection volume with the graduated cylinder. Test each fuel injector assembly 2 or 3 times. 09842-30090Standard Injection Volume:

Difference between Each Fuel Injector Assembly: 14 cc (0.9 cu. in.) or less NOTICE:

If the injection volume is not as specified, replace the fuel injector assembly. |

|

(c) Check for leaks.

(1) Disconnect SST (EFI inspection wire I) from the battery and check for fuel leaks from the fuel injector assembly.

Standard Fuel Drop:

1 drop or less per 20 minutes

If the result is not as specified, replace the fuel injector assembly.

(2) Connect the fuel tube sub-assembly.

(3) Install the No. 1 fuel pipe clamp to the fuel tube connector.

(4) Engage the 2 claws to install the No. 2 fuel pipe clamp.

(5) Check for fuel leaks.

|

|

|

![2018 - 2019 MY Camry [06/2017 - 09/2019]; 2GR-FKS (FUEL): FUEL SYSTEM: PRECAUTION](/t3Portal/stylegraphics/info.gif)