- Cooling effectiveness is poor

- Cooling response is slow

| Last Modified: 09-09-2025 | 6.11:8.1.0 | Doc ID: RM1000000015EO2 |

| Model Year Start: 2018 | Model: Camry | Prod Date Range: [06/2017 - 10/2020] |

| Title: HEATING / AIR CONDITIONING: AIR CONDITIONING SYSTEM (for Automatic Air Conditioning System): Cooling System; 2018 - 2020 MY Camry [06/2017 - 10/2020] | ||

|

Cooling System |

DESCRIPTION

If the cooling effect of the air conditioning system is weak, the following suspected areas may be the cause.

|

Symptom |

Factor |

|---|---|

|

|

|

- *1: for A25A-FKS

- *2: for 2GR-FKS

WIRING DIAGRAM

PROCEDURE

PROCEDURE

|

1. |

PERFORM REFRIGERANT SHORTAGE CHECK |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Utility / Refrigerant Gas Volume Check.

Body Electrical > Air Conditioner > Utility

|

Tester Display |

|---|

|

Refrigerant Gas Volume Check |

(e) Check that the following conditions are met and perform the refrigerant shortage check according to the display on the Techstream.

Measurement Condition:

|

Item |

Condition |

|---|---|

|

A/C switch |

On |

|

Ambient temperature* |

0 to 49°C (32 to 120°F) |

|

Blower speed |

HI |

*: If the ambient temperature is not within the range shown, do not perform this check.

|

Result |

Amount of Refrigerant |

|---|---|

|

Refrigerant correct |

Correct |

|

Refrigerant shortage |

Insufficient |

OK:

"Refrigerant correct" is displayed on Techstream.

| NG |

|

REPAIR REFRIGERANT LEAK |

|

|

2. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Blower Motor |

Blower motor with fan sub-assembly |

Min.: 0 Max.: 31 |

- |

|

Air Mix Servo Targ Pulse(D) |

No. 1 air conditioning radiator damper servo sub-assembly (driver side air mix*1 or air mix*2) pulse |

Min.: 128 Max.: 383 |

Operates between 165 to 257 pulses |

|

Air Mix Servo Targ Pulse(P) |

No. 1 air conditioning radiator damper servo sub-assembly (front passenger side air mix) pulse*1 |

Min.: 128 Max.: 383 |

Operates between 255 to 347 pulses |

|

Air Outlet Servo Pulse (D) |

No. 1 air conditioning radiator damper servo sub-assembly (mode) pulse |

Min.: 128 Max.: 383 |

Operates between 241 to 348 pulses |

|

Air Inlet Damper Targ Pulse |

No. 1 blower damper servo sub-assembly pulse |

Min.: 128 Max.: 383 |

Operates between 220 to 256 pulses |

|

A/O Servo Pulse(Rr D) |

No. 2 air conditioning radiator damper servo sub-assembly pulse*1 |

Min.: 128 Max.: 383 |

Operates between 158 to 260 pulses |

- *1: for Dual Type

- *2: for Single Type

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

|---|

|

Blower Motor |

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

|---|

|

Air Mix Servo Targ Pulse(D) |

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

|---|

|

Air Mix Servo Targ Pulse(P) |

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

|---|

|

Air Outlet Servo Pulse (D) |

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

|---|

|

Air Inlet Damper Targ Pulse |

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

|---|

|

A/O Servo Pulse(Rr D) |

OK:

The blower motor with fan sub-assembly and each damper servo motor operates.

| NG |

|

GO TO DTC TROUBLESHOOTING PROCEDURE FOR MALFUNCTIONING DAMPER SERVO MOTOR |

|

|

3. |

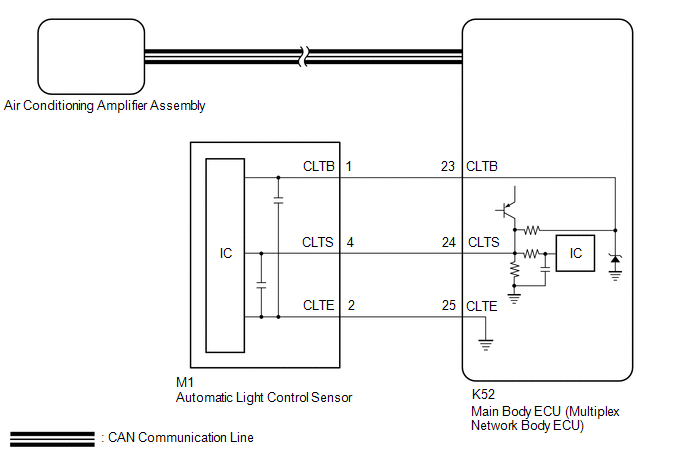

INSPECT WIRE HARNESS AND CONNECTOR (AUTOMATIC LIGHT CONTROL SENSOR - MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

(a) Disconnect the M1 automatic light control sensor connector.

(b) Disconnect the K52 main body ECU (multiplex network body ECU) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M1-1 (CLTB) - K52-23 (CLTB) |

Always |

Below 1 Ω |

|

M1-2 (CLTE) - K52-25 (CLTE) |

Always |

Below 1 Ω |

|

M1-4 (CLTS) - K52-24 (CLTS) |

Always |

Below 1 Ω |

|

M1-1 (CLTB) or K52-23 (CLTB) - Other terminals and body ground |

Always |

10 kΩ or higher |

|

M1-2 (CLTE) or K52-25 (CLTE) - Other terminals and body ground |

Always |

10 kΩ or higher |

|

M1-4 (CLTS) or K52-24 (CLTS) - Other terminals and body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

INSPECT AUTOMATIC LIGHT CONTROL SENSOR |

(a) Remove the automatic light control sensor.

(b) Inspect the automatic light control sensor.

| OK |

|

INSPECT REFRIGERANT PRESSURE WITH MANIFOLD GAUGE SET |

| NG |

|

|

|

|

![2018 - 2020 MY Camry [06/2017 - 10/2020]; HEATING / AIR CONDITIONING: REFRIGERANT (for HFC-134a(R134a)): REPLACEMENT](/t3Portal/stylegraphics/info.gif)