- Cooler compressor assembly does not stop operating

- Refrigerant pressure does not decrease when A/C switch is turned off

| Last Modified: 09-09-2025 | 6.11:8.1.0 | Doc ID: RM10000000159BE |

| Model Year Start: 2018 | Model: Camry | Prod Date Range: [06/2017 - ] |

| Title: HEATING / AIR CONDITIONING: AIR CONDITIONING SYSTEM (for Automatic Air Conditioning System): Air Conditioning Compressor Magnetic Clutch Circuit; 2018 - 2024 MY Camry [06/2017 - ] | ||

|

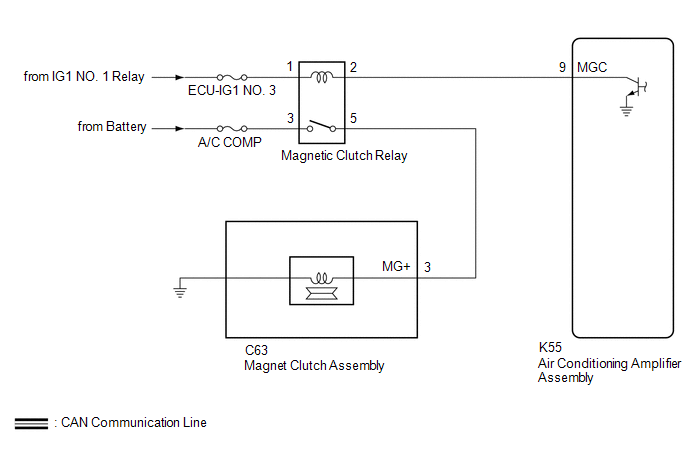

Air Conditioning Compressor Magnetic Clutch Circuit |

DESCRIPTION

When the engine is running, If refrigerant pressure does not decrease when the A/C switch is turned off, the following suspected areas may be the cause.

|

Symptom |

Factor |

|---|---|

|

|

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

PROCEDURE

|

1. |

INSPECT MAGNETIC CLUTCH RELAY |

(a) Remove the magnetic clutch relay.

(b) Inspect the magnetic clutch relay.

| NG |

|

REPLACE MAGNETIC CLUTCH RELAY |

|

|

2. |

CHECK HARNESS AND CONNECTOR (MAGNETIC CLUTCH RELAY - POWER SOURCE) |

(a) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Relay terminal 3 - Body ground |

Always |

11 to 14 V |

|

Relay terminal 1 - Body ground |

Ignition switch off |

Below 1 V |

|

Relay terminal 1 - Body ground |

Ignition switch ON |

11 to 14 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK HARNESS AND CONNECTOR (MAGNETIC CLUTCH RELAY - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the K55 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Relay terminal 2 - K55-9 (MGC) |

Always |

Below 1 Ω |

|

Relay terminal 2 or K55-9 (MGC) - Other terminals and body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK HARNESS AND CONNECTOR (MAGNETIC CLUTCH RELAY - MAGNET CLUTCH ASSEMBLY AND BODY GROUND) |

(a) Disconnect the C63 magnet clutch assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Relay terminal 5 - C63-3 (MG+) |

Always |

Below 1 Ω |

|

Relay terminal 5 - C63-3 (MG+) - Other terminals and body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

CHECK HARNESS AND CONNECTOR (MAGNET CLUTCH ASSEMBLY - BODY GROUND) |

(a) Install the magnetic clutch relay.

(b) Connect the C63 magnet clutch assembly connector.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C63-3 (MG+) - Body ground |

Engine running (A/C switch: Off) |

Below 1 V |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2018 - 2024 MY Camry [06/2017 - ]; HEATING / AIR CONDITIONING: RELAY: ON-VEHICLE INSPECTION](/t3Portal/stylegraphics/info.gif)