| Last Modified: 11-20-2023 | 6.11:8.1.0 | Doc ID: RM1000000014V5W |

| Model Year Start: 2018 | Model: Camry | Prod Date Range: [06/2017 - ] |

| Title: LIGHTING (INT): LIGHTING SYSTEM: Footwell Light Circuit; 2018 - 2024 MY Camry [06/2017 - ] | ||

|

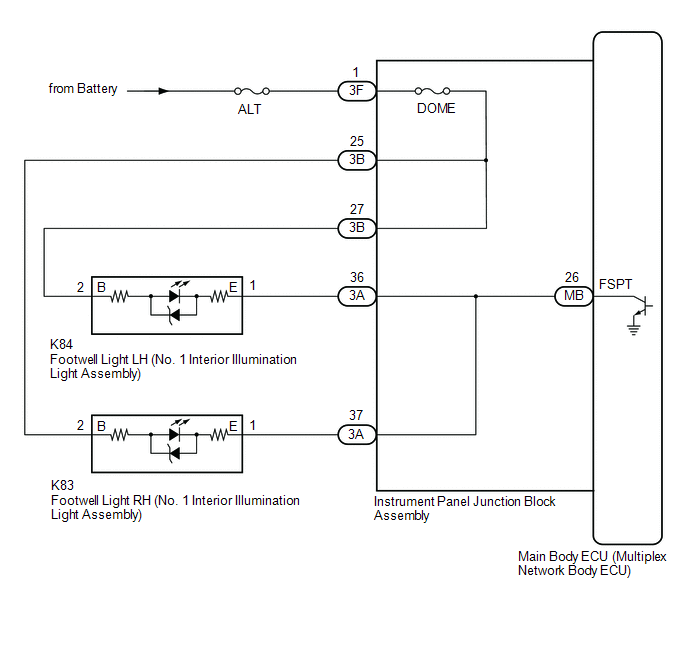

Footwell Light Circuit |

DESCRIPTION

The main body ECU (multiplex network body ECU) controls the operation of the following lights:

- Footwell Light LH (No. 1 Interior Illumination Light Assembly)

- Footwell Light RH (No. 1 Interior Illumination Light Assembly)

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- *: w/ Smart Key System

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Main Body > Active Test

|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Fr Foot Light |

Footwell light (No. 1 interior illumination light assembly) |

OFF or ON |

Preconditions for using the Active Test to check dimmer controlled illumination:

|

Body Electrical > Main Body > Active Test

|

Tester Display |

|---|

|

Fr Foot Light |

OK:

Footwell lights come on.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (Footwell light LH does not come on) |

B |

|

NG (Footwell light RH does not come on) |

C |

|

NG (Footwell light LH and RH do not come on) |

D |

| A |

|

| C |

|

| D |

|

|

|

2. |

INSPECT FOOTWELL LIGHT LH (NO. 1 INTERIOR ILLUMINATION LIGHT ASSEMBLY) |

(a) Remove the footwell light LH (No. 1 interior illumination light assembly).

(b) Inspect the footwell light LH (No. 1 interior illumination light assembly).

| NG |

|

REPLACE FOOTWELL LIGHT LH (NO. 1 INTERIOR ILLUMINATION LIGHT ASSEMBLY) |

|

|

3. |

CHECK HARNESS AND CONNECTOR (FOOTWELL LIGHT LH (NO. 1 INTERIOR ILLUMINATION LIGHT ASSEMBLY) - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY) |

(a) Disconnect the 3A and 3B instrument panel junction block assembly connectors.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

K84-1 (E) - 3A-36 |

Always |

Below 1 Ω |

|

K84-2 (B) - 3B-27 |

Always |

Below 1 Ω |

|

K84-1 (E) or 3A-36 - Body ground |

Always |

10 kΩ or higher |

|

K84-2 (B) or 3B-27 - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

|

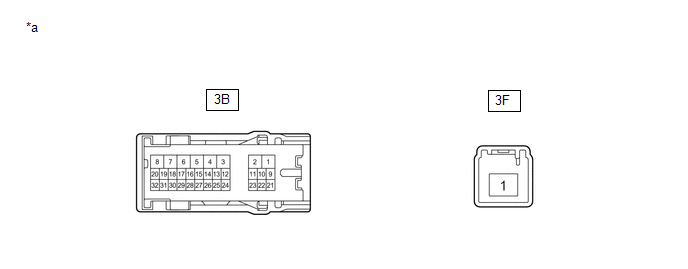

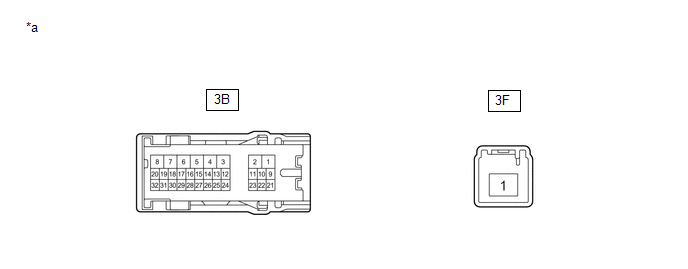

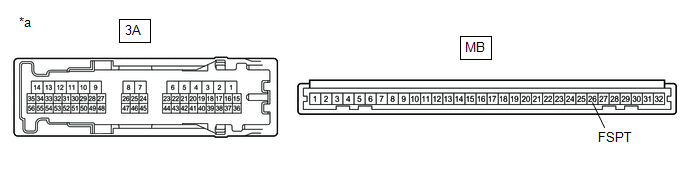

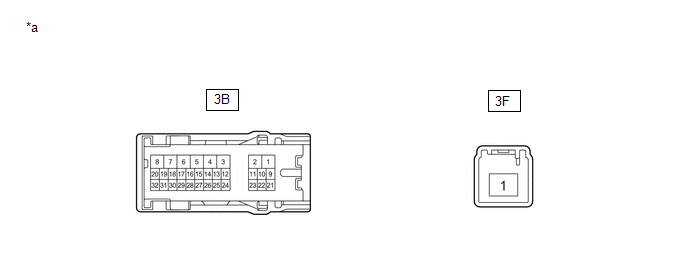

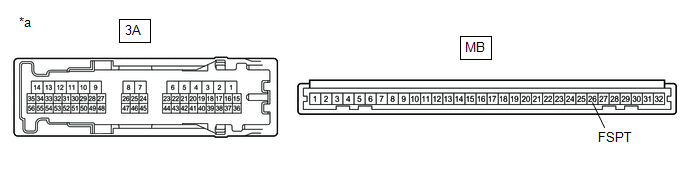

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

- |

- |

(a) Disconnect the 3F instrument panel junction block assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3B-27 - 3F-1 |

Always |

Below 1 Ω |

| NG |

|

|

|

5. |

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

|

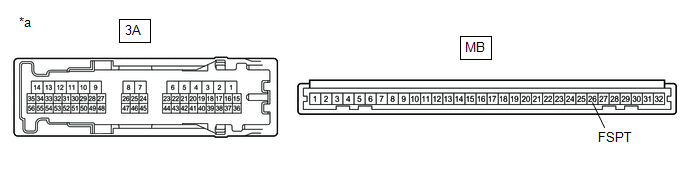

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

- |

- |

(a) Remove the instrument panel junction block assembly.

(b) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3A-36 - MB-26 (FSPT) |

Always |

Below 1 Ω |

| OK |

|

| NG |

|

|

6. |

INSPECT FOOTWELL LIGHT RH (NO. 1 INTERIOR ILLUMINATION LIGHT ASSEMBLY) |

(a) Remove the footwell light RH (No. 1 interior illumination light assembly).

(b) Inspect the footwell light RH (No. 1 interior illumination light assembly).

| NG |

|

REPLACE FOOTWELL LIGHT RH (NO. 1 INTERIOR ILLUMINATION LIGHT ASSEMBLY) |

|

|

7. |

CHECK HARNESS AND CONNECTOR (FOOTWELL LIGHT RH (NO. 1 INTERIOR ILLUMINATION LIGHT ASSEMBLY) - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY) |

(a) Disconnect the 3A and 3B instrument panel junction block assembly connectors.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

K83-1 (E) - 3A-37 |

Always |

Below 1 Ω |

|

K83-2 (B) - 3B-25 |

Always |

Below 1 Ω |

|

K83-1 (E) or 3A-37 - Body ground |

Always |

10 kΩ or higher |

|

K83-2 (B) or 3B-25 - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

8. |

CHECK INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

|

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

- |

- |

(a) Disconnect the 3F instrument panel junction block assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3B-25 - 3F-1 |

Always |

Below 1 Ω |

| NG |

|

|

|

9. |

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

|

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

- |

- |

(a) Remove the instrument panel junction block assembly.

(b) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3A-37 - MB-26 (FSPT) |

Always |

Below 1 Ω |

| OK |

|

| NG |

|

|

10. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY) |

(a) Disconnect the 3F instrument panel junction block assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3F-1 - Body ground |

Always |

11 to 14 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

11. |

CHECK INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

|

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

- |

- |

(a) Disconnect the 3B instrument panel junction block assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3B-27 - 3F-1 |

Always |

Below 1 Ω |

|

3B-25 - 3F-1 |

Always |

Below 1 Ω |

| NG |

|

|

|

12. |

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

|

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

- |

- |

(a) Remove the instrument panel junction block assembly.

(b) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3A-36 - MB-26 (FSPT) |

Always |

Below 1 Ω |

|

3A-37 - MB-26 (FSPT) |

Always |

Below 1 Ω |

| OK |

|

| NG |

|

|

|

|

![2018 - 2019 MY Camry [03/2017 - 09/2019]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function): REGISTRATION](/t3Portal/stylegraphics/info.gif)