| Last Modified: 11-20-2023 | 6.11:8.1.0 | Doc ID: RM1000000014SZN |

| Model Year Start: 2018 | Model: Camry | Prod Date Range: [06/2017 - 09/2019] |

| Title: HEATING / AIR CONDITIONING: AIR CONDITIONING UNIT: INSTALLATION; 2018 - 2019 MY Camry [06/2017 - 09/2019] | ||

INSTALLATION

PROCEDURE

1. TEMPORARILY INSTALL AIR CONDITIONER UNIT ASSEMBLY

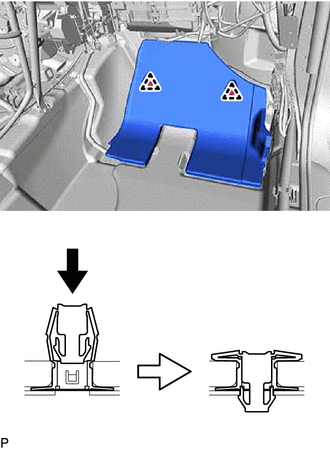

(a) w/ Claw:

(1) Engage the 2 claws.

(b) Temporarily install the air conditioner unit assembly to the instrument panel reinforcement assembly with the 3 bolts.

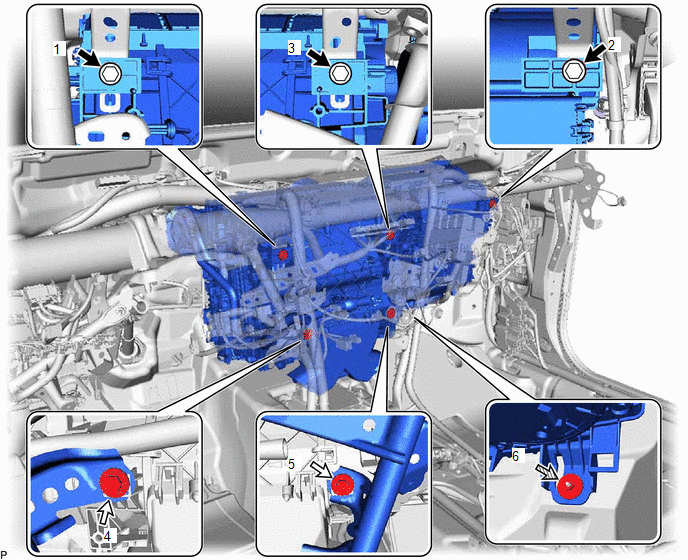

2. INSTALL INSTRUMENT PANEL REINFORCEMENT ASSEMBLY WITH AIR CONDITIONER UNIT ASSEMBLY

NOTICE:

- Be sure to support the air conditioner unit assembly when installing it. Failure to do so may cause the bracket of the air conditioner unit assembly to break.

- When installing the air conditioner unit assembly, eliminate static electricity by touching the vehicle body to prevent the components from being damaged.

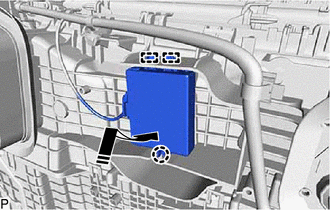

(a) Engage the 2 guides and claw to connect the ID code box (immobiliser code ECU) as shown in the illustration.

|

Install in this Direction |

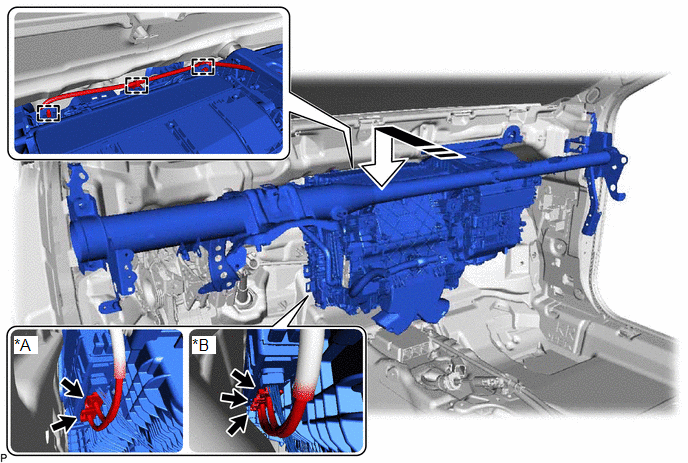

(b) Connect each connector.

|

*A |

w/o Seat Heater |

*B |

w/ Seat Heater |

|

Install in this Direction |

- |

- |

(c) Engage each clamp.

(d) Temporarily install the instrument panel reinforcement assembly with air conditioner unit assembly as shown in the illustration.

(e) Install the 4 bolts (A).

Torque:

25 N·m {255 kgf·cm, 18 ft·lbf}

(f) Connect the brake pedal assembly with the bolt (B).

Torque:

15 N·m {153 kgf·cm, 11 ft·lbf}

(g) Temporarily install the nut.

(h) Install the 3 bolts.

Torque:

25 N·m {255 kgf·cm, 18 ft·lbf}

(i) Install the 2 hole plugs.

|

(j) Install a new cooler unit drain hose grommet. NOTICE:

|

|

(k) Connect the drain cooler hose.

|

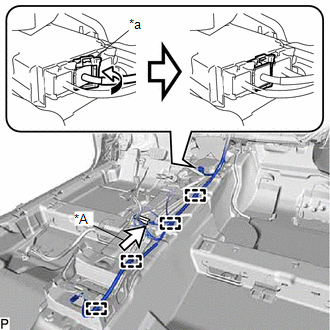

(l) Install the front floor mat to its original position as shown in the illustration. |

|

(m) Engage each clamp.

|

*A |

w/ Smart Key System |

|

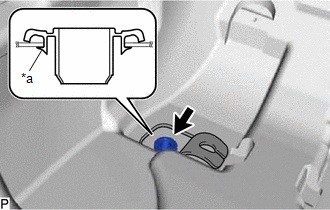

*a |

Lock Lever |

|

Move in this Direction |

(n) Temporarily connect the connector and then move the lock lever as shown in the illustration to securely connect the connector.

NOTICE:

When connecting any airbag connector, take care not to damage the airbag wire harness.

(o) Check that there is no looseness in the installed parts of the airbag sensor assembly.

(p) w/ Smart Key System:

(1) Connect the connector.

(q) Engage each clamp.

(r) Connect the connector holder with the 2 nuts.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

(s) Connect the 3 earth wires with the 3 bolts.

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

(t) Connect the connector.

3. INSTALL INSTRUMENT PANEL TO PEDAL BRACKET (for Pedal Type Parking Brake)

(a) Engage the guide to install the instrument panel to pedal bracket with the bolt and nut.

Torque:

Bolt :

15 N·m {153 kgf·cm, 11 ft·lbf}

Nut :

18 N·m {184 kgf·cm, 13 ft·lbf}

4. INSTALL NO. 2 AIR DUCT SUB-ASSEMBLY

(a) Engage the 4 claws to install the No. 2 air duct sub-assembly.

5. INSTALL INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY WITH MAIN BODY ECU

6. INSTALL NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY

(a) Install the No. 3 instrument panel to cowl brace sub-assembly with the bolt and nut.

Torque:

Bolt :

10 N·m {102 kgf·cm, 7 ft·lbf}

Nut :

10 N·m {102 kgf·cm, 7 ft·lbf}

(b) Engage each clamp.

7. INSTALL NO. 2 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

(a) Install the No. 2 instrument panel brace sub-assembly with the bolt and nut.

Torque:

Bolt :

20 N·m {204 kgf·cm, 15 ft·lbf}

Nut :

18 N·m {184 kgf·cm, 13 ft·lbf}

(b) Temporarily install the screw.

HINT:

Do not fully tighten the screw.

(c) Engage each clamp.

(d) Connect the relay block assembly with the bolt (B).

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

(e) Connect the earth wire with the bolt (A).

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

8. INSTALL NO. 1 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

(a) Install the No. 1 instrument panel brace sub-assembly with the bolt and nut.

Torque:

Bolt :

20 N·m {204 kgf·cm, 15 ft·lbf}

Nut :

18 N·m {184 kgf·cm, 13 ft·lbf}

(b) Temporarily install the screw.

HINT:

Do not fully tighten the screw.

(c) Engage each clamp.

(d) Connect the earth wire with the bolt.

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

9. INSTALL AIR CONDITIONER UNIT ASSEMBLY

(a) Tighten the 3 bolts, 2 screws and nut to install the air conditioner unit assembly.

|

Bolt |

|

Screw |

|

Nut |

- |

- |

Torque:

Bolt :

9.8 N·m {100 kgf·cm, 87 in·lbf}

Nut :

9.8 N·m {100 kgf·cm, 87 in·lbf}

NOTICE:

Tighten the bolts, screws and nut in the order shown in the illustration.

10. INSTALL NO. 3 DASH PANEL INSULATOR PAD

|

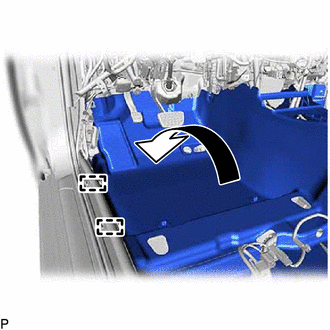

(a) Install the No. 3 dash panel insulator pad with 2 new clips as shown in the illustration. |

|

11. INSTALL NO. 1 CONSOLE BOX DUCT (for Dual Type)

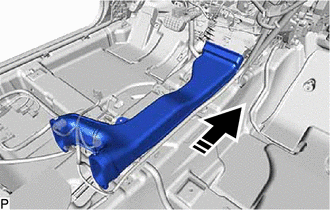

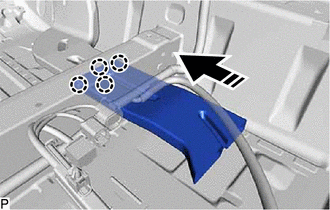

(a) Install the No. 1 console box duct as shown in the illustration.

|

Install in this Direction |

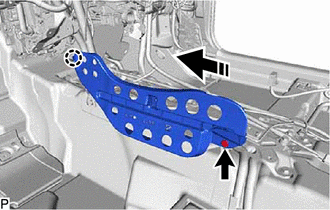

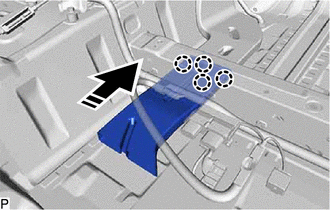

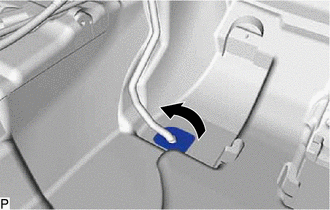

12. INSTALL FLOOR CARPET BRACKET LH

(a) Engage the claw as shown in the illustration.

|

Install in this Direction |

(b) Install the floor carpet bracket LH with the clip.

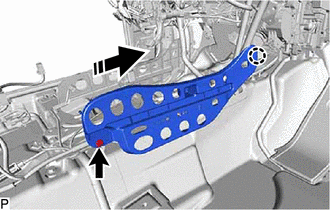

13. INSTALL FLOOR CARPET BRACKET RH

(a) Engage the claw as shown in the illustration.

|

Install in this Direction |

(b) Install the floor carpet bracket RH with the clip.

14. INSTALL REAR NO. 3 AIR DUCT

(a) Engage the 2 claws to install the rear No. 3 air duct.

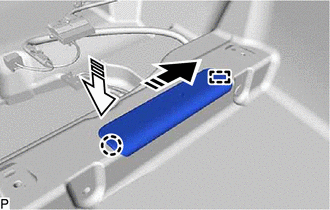

15. INSTALL REAR NO. 4 AIR DUCT

(a) Engage the 4 claws to install the rear No. 4 air duct as shown in the illustration.

|

Install in this Direction |

|

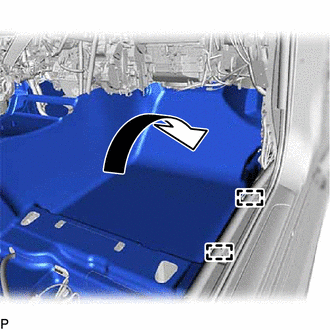

(b) Install the front floor carpet assembly to its original position as shown in the illustration. |

|

(c) Engage the 2 guides.

(d) Install the 2 front floor carpet clips.

16. INSTALL REAR NO. 1 AIR DUCT

(a) Engage the 2 claws to install the rear No. 1 air duct.

17. INSTALL REAR NO. 2 AIR DUCT

(a) Engage the 4 claws to install the rear No. 2 air duct as shown in the illustration.

|

Install in this Direction |

|

(b) Install the front floor carpet assembly to its original position as shown in the illustration. |

|

(c) Engage the 2 guides.

(d) Install the 2 front floor carpet clips.

18. INSTALL FRONT FLOOR CAUTION PLATE COVER (for TMC Made)

(a) Engage the guide and claw to install the front floor caution plate cover as indicated by the arrows, in the order shown in the illustration.

|

Install in this Direction (1) |

|

Install in this Direction (2) |

19. INSTALL ACCELERATOR PEDAL

for A25A-FKS:

for 2GR-FKS:

20. INSTALL ACCELERATOR PEDAL PAD

for A25A-FKS:

for 2GR-FKS:

21. INSTALL COOLER (ROOM TEMP. SENSOR) THERMISTOR

(a) Connect the aspirator and connector to install the cooler (room temp. sensor) thermistor.

22. INSTALL NO. 1 CLEARANCE WARNING BUZZER (w/ Intuitive Parking Assist System)

23. INSTALL DCM (TELEMATICS TRANSCEIVER) (w/ Manual (SOS) Switch)

24. INSTALL CENTRAL GATEWAY ECU (NETWORK GATEWAY ECU) (w/o Smart Key System)

25. INSTALL ECU INTEGRATION BOX RH (w/ Smart Key System)

26. INSTALL INSTRUMENT PANEL SAFETY PAD SUB-ASSEMBLY

27. INSTALL STEERING COLUMN ASSEMBLY

28. INSTALL TRANSMISSION FLOOR SHIFT ASSEMBLY

for UB80E Automatic Transmission / Transaxle:

for UA80E Automatic Transmission / Transaxle:

29. INSTALL FRONT SEAT ASSEMBLY LH (for Manual Seat)

for TMMK Made:

30. INSTALL FRONT SEAT ASSEMBLY RH (for Manual Seat)

for TMC Made:

for TMMK Made:

HINT:

Use the same procedure as for the LH side.

31. INSTALL FRONT SEAT ASSEMBLY LH (for Power Seat)

for TMC Made:

for TMMK Made:

32. INSTALL FRONT SEAT ASSEMBLY RH (for Power Seat)

for TMMK Made:

HINT:

Use the same procedure as for the LH side.

33. CONNECT AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY (w/o Sub-cool Accelerator)

(a) Remove the vinyl tape from the air conditioning tube and accessory assembly.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the air conditioning tube and accessory assembly.

|

Refrigerant |

Compressor Oil |

|---|---|

|

HFC-134a (R134a) |

ND-OIL 8 or equivalent |

|

HFO-1234yf (R1234yf) |

ND-OIL 12 or equivalent |

(c) Install the O-ring to the air conditioning tube and accessory assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(d) Connect the air conditioning tube and accessory assembly.

34. CONNECT SUCTION PIPE SUB-ASSEMBLY (w/o Sub-cool Accelerator)

(a) Remove the vinyl tape from the suction pipe sub-assembly.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the suction pipe sub-assembly.

|

Refrigerant |

Compressor Oil |

|---|---|

|

HFC-134a (R134a) |

ND-OIL 8 or equivalent |

|

HFO-1234yf (R1234yf) |

ND-OIL 12 or equivalent |

(c) Install the O-ring to the suction pipe sub-assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(d) Connect the suction pipe sub-assembly.

|

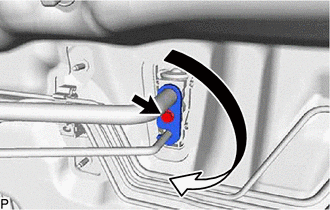

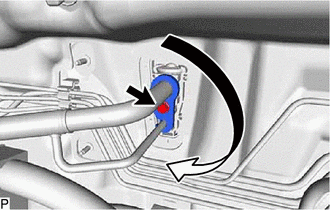

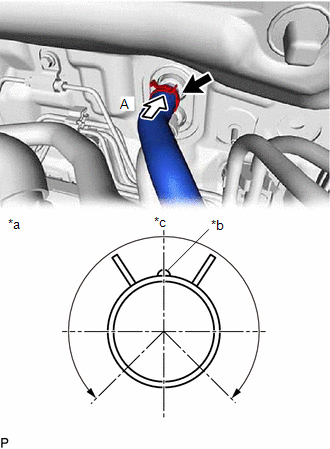

(e) Rotate the hook connector as shown in the illustration. |

|

(f) Insert the tube joint into the fitting hole securely and install the bolt.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

35. CONNECT NO. 2 AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY (w/ Sub-cool Accelerator)

(a) Remove the vinyl tape from the No. 2 air conditioning tube and accessory assembly.

(b) Sufficiently apply compressor oil to 2 new O-rings and the fitting surfaces of the No. 2 air conditioning tube and accessory assembly.

Compressor Oil:

ND-OIL 12 or equivalent

(c) Install the 2 O-rings to the No. 2 air conditioning tube and accessory assembly.

NOTICE:

Keep the O-rings and O-ring fitting surfaces free of foreign matter.

(d) Connect the No. 2 air conditioning tube and accessory assembly.

|

(e) Rotate the hook connector as shown in the illustration. |

|

(f) Insert the tube joint into the fitting hole securely and install the bolt.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

36. CONNECT INLET HEATER WATER HOSE (for A25A-FKS)

|

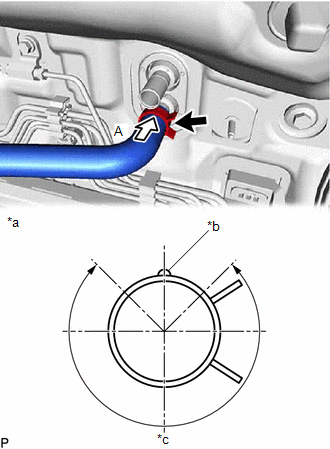

(a) Connect the inlet heater water hose with the marking facing up and engage the clip within the area shown in the illustration. NOTICE: Do not apply excessive force to the inlet heater water hose. |

|

37. CONNECT INLET HEATER WATER HOSE (for 2GR-FKS)

|

(a) Connect the inlet heater water hose with the marking facing up and engage the clip within the area shown in the illustration. NOTICE: Do not apply excessive force to the inlet heater water hose. |

|

38. CONNECT OUTLET HEATER WATER HOSE (for A25A-FKS)

|

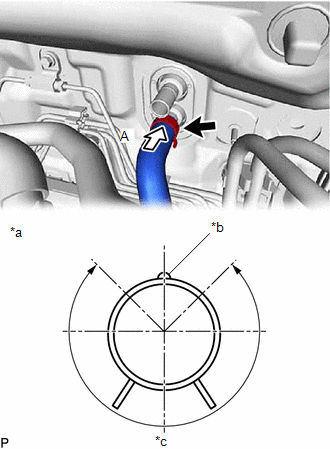

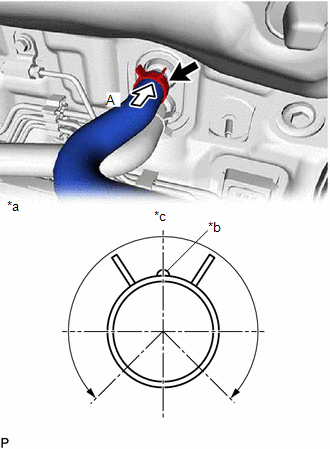

(a) Connect the outlet heater water hose with the marking facing up and engage the clip within the area shown in the illustration. NOTICE: Do not apply excessive force to the outlet heater water hose. |

|

39. CONNECT OUTLET HEATER WATER HOSE A (for 2GR-FKS)

|

(a) Connect the outlet heater water hose A with the marking facing up and engage the clip within the area shown in the illustration. NOTICE: Do not apply excessive force to the outlet heater water hose A. |

|

40. INSTALL FRONT CENTER UPPER SUSPENSION BRACE SUB-ASSEMBLY

41. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

42. ADD ENGINE COOLANT

for A25A-FKS:

for 2GR-FKS:

43. INSPECT FOR COOLANT LEAK

for A25A-FKS:

for 2GR-FKS:

44. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

for HFC-134a (R134a):

for HFO-1234yf (R1234yf):

45. WARM UP ENGINE

for HFC-134a (R134a):

for HFO-1234yf (R1234yf):

46. INSPECT FOR REFRIGERANT LEAK

for HFC-134a (R134a):

for HFO-1234yf (R1234yf):

|

|

|

![2018 - 2024 MY Camry [03/2017 - ]; POWER DISTRIBUTION: MAIN BODY ECU: INSTALLATION+](/t3Portal/stylegraphics/info.gif)