- Gas leak from exhaust system is repaired

- Replacement of air fuel ratio sensor

| Last Modified: 11-20-2023 | 6.11:8.1.0 | Doc ID: RM1000000012VDJ |

| Model Year Start: 2018 | Model: Camry | Prod Date Range: [03/2017 - 06/2017] |

| Title: A25A-FKS (ENGINE MECHANICAL): REAR CRANKSHAFT OIL SEAL: REMOVAL; 2018 MY Camry [03/2017 - 06/2017] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rear crankshaft oil seal removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane departure alert system (w/ Steering Control) |

|

|

Pre-collision system |

|||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

||

|

Replacement of ECM |

Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

||

|

|

Inspection After Repair |

|

|

|

Replacement of automatic transaxle assembly |

|

|

|

|

Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) |

|

||

|

Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) |

|

||

|

Replacement of ECM*1 |

Code registration (Smart key System (for Start Function)) |

|

|

|

Replacement of ECM*2 |

Code registration (Immobiliser system (w/o Smart Key System)) |

|

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Rear television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

Front wheel alignment adjustment |

Perform system variant learning and acceleration sensor zero point calibration. |

|

- *1: w/ Smart Key System

- *2: w/o Smart Key System

- *3: When the ECM is replaced with a new one, reset memory is unnecessary.

NOTICE:

This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

PROCEDURE

1. REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

2. REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

(a) Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat level surface.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly level.

- To prevent the No. 2 oil pan sub-assembly from deforming, do not place any attachments under the No. 2 oil pan sub-assembly of the engine assembly.

- Using an engine sling device and engine lift, secure the engine assembly before servicing.

|

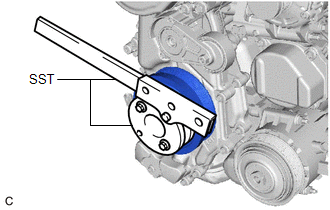

(b) Using SST, hold the crankshaft pulley assembly. SST: 09213-54015 SST: 09330-00021 |

|

|

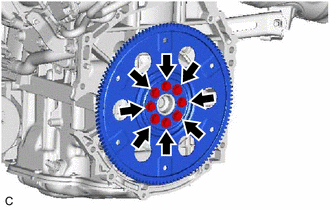

(c) Remove the 8 bolts, rear drive plate spacer, drive plate and ring gear sub-assembly. |

|

3. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

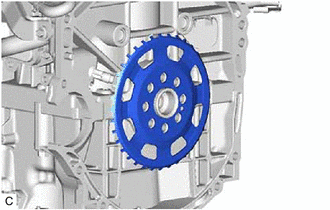

(a) Type A:

|

(1) Remove the No. 1 crankshaft position sensor plate. |

|

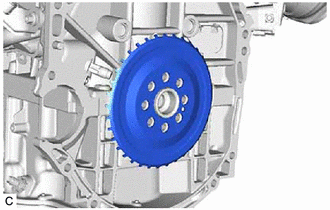

(b) Type B:

|

(1) Remove the No. 1 crankshaft position sensor plate. |

|

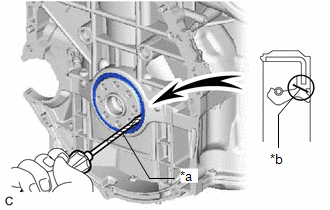

4. REMOVE REAR ENGINE OIL SEAL

|

(a) Using a knife, cut off the lip of the rear engine oil seal. |

|

(b) Using a screwdriver, pry out the rear engine oil seal.

NOTICE:

Do not damage the surface of the rear engine oil seal press fit hole or the crankshaft.

HINT:

Tape the screwdriver tip before use.

|

|

|

![2018 - 2020 MY Camry [03/2017 - 10/2020]; PRE-COLLISION: PRE-COLLISION SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)