| Last Modified: 11-20-2023 | 6.11:8.1.0 | Doc ID: RM1000000012T2J |

| Model Year Start: 2018 | Model: Camry | Prod Date Range: [03/2017 - ] |

| Title: A25A-FKS (ENGINE MECHANICAL): CYLINDER HEAD: INSPECTION; 2018 - 2024 MY Camry [03/2017 - ] | ||

INSPECTION

PROCEDURE

1. INSPECT CYLINDER HEAD SUB-ASSEMBLY

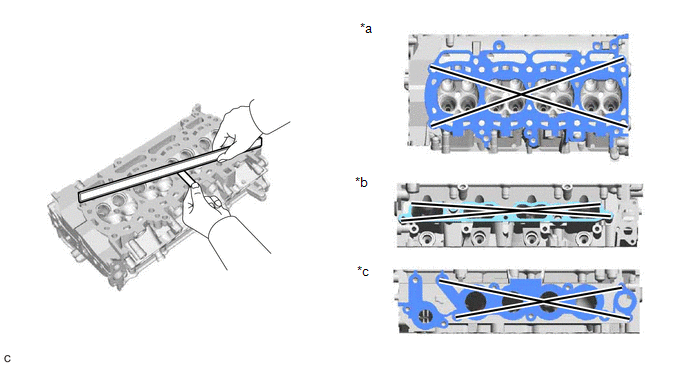

(a) Using a precision straightedge and feeler gauge, measure the warpage of the contact surfaces where the cylinder head sub-assembly contacts the cylinder block sub-assembly, intake manifold and exhaust manifold (TWC: Front Catalyst).

|

*a |

Bottom Side |

*b |

Intake Manifold Side |

|

*c |

Exhaust Manifold (TWC: Front Catalyst) Side |

- |

- |

Maximum Warpage:

|

Item |

Specified Condition |

|---|---|

|

Bottom side |

0.05 mm (0.00197 in.) |

|

Intake manifold side |

0.10 mm (0.00394 in.) |

|

Exhaust manifold (TWC: Front Catalyst) side |

0.10 mm (0.00394 in.) |

HINT:

If the warpage is more than the maximum, replace the cylinder head sub-assembly.

|

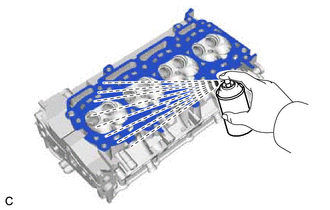

(b) Using a dye penetrant, check the intake ports, exhaust ports and cylinder head sub-assembly surface for cracks. HINT: If cracks are found, replace the cylinder head sub-assembly. |

|

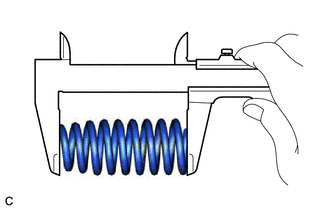

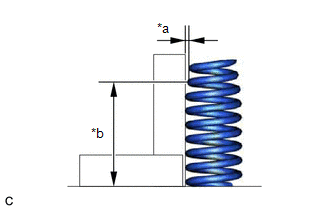

2. INSPECT COMPRESSION SPRING

(a) Intake Side:

|

(1) Using a vernier caliper, measure the free length of the compression spring. Standard Free Length: 53.71 mm (2.11 in.) HINT: If the free length is not as specified, replace the compression spring. |

|

|

(2) Using a steel square, measure the deviation of the compression spring. Maximum Deviation (Reference): 1.0 mm (0.0394 in.) HINT: If the deviation is more than the maximum, replace the compression spring. |

|

(b) Exhaust Side:

|

(1) Using a vernier caliper, measure the free length of the compression spring. Standard Free Length: 55.11 mm (2.17 in.) HINT: If the free length is not as specified, replace the compression spring. |

|

|

(2) Using a steel square, measure the deviation of the compression spring. Maximum Deviation (Reference): 1.0 mm (0.0394 in.) HINT: If the deviation is more than the maximum, replace the compression spring. |

|

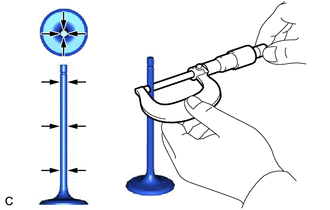

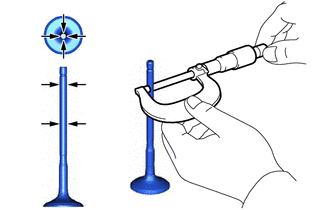

3. INSPECT INTAKE VALVE

|

(a) Using a micrometer, measure the diameter of the valve stem. Standard Valve Stem Diameter: 5.470 to 5.485 mm (0.215 to 0.216 in.) HINT: If the valve stem diameter is not as specified, check the intake valve guide bush oil clearance. |

|

|

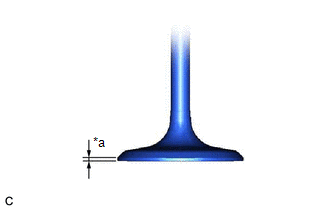

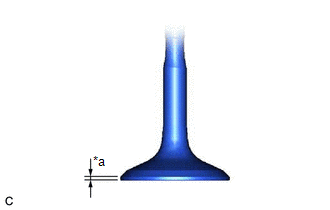

(b) Using a vernier caliper, measure the valve head margin thickness. Standard Margin Thickness: 1.0 mm (0.0394 in.) Minimum Margin Thickness: 0.5 mm (0.0197 in.) HINT: If the margin thickness is less than the minimum, replace the intake valve. |

|

|

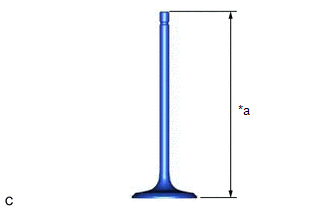

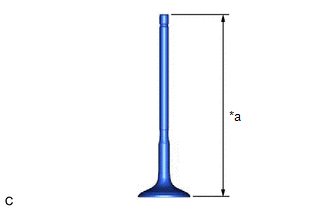

(c) Using a vernier caliper, measure the overall length of the intake valve. Standard Overall Length: 104.45 mm (4.11 in.) Minimum Overall Length: 103.95 mm (4.09 in.) HINT: If the overall length is less than the minimum, replace the intake valve. |

|

4. INSPECT EXHAUST VALVE

|

(a) Using a micrometer, measure the diameter of the valve stem. Standard Valve Stem Diameter: 5.465 to 5.480 mm (0.215 to 0.216 in.) HINT: If the valve stem diameter is not as specified, check the exhaust valve guide bush oil clearance. |

|

|

(b) Using a vernier caliper, measure the valve head margin thickness. Standard Margin Thickness: 1.0 mm (0.0394 in.) Minimum Margin Thickness: 0.5 mm (0.0197 in.) HINT: If the margin thickness is less than the minimum, replace the exhaust valve. |

|

|

(c) Using a vernier caliper, measure the overall length of the exhaust valve. Standard Overall Length: 108.7 mm (4.28 in.) Minimum Overall Length: 108.2 mm (4.26 in.) HINT: If the overall length is less than the minimum, replace the exhaust valve. |

|

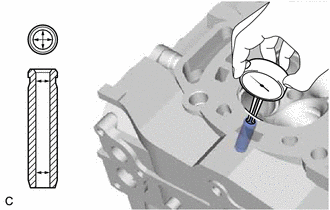

5. INSPECT VALVE GUIDE BUSH OIL CLEARANCE

|

(a) Using a caliper gauge, measure the inside diameter of the valve guide bush. Standard Valve Guide Bush Inside Diameter: 5.51 to 5.53 mm (0.217 to 0.218 in.) |

|

(b) Subtract the valve stem diameter measurement from the valve guide bush inside diameter measurement.

Standard Oil Clearance:

|

Item |

Specified Condition |

|---|---|

|

Intake Side |

0.025 to 0.060 mm (0.000984 to 0.00236 in.) |

|

Exhaust Side |

0.030 to 0.065 mm (0.00118 to 0.00256 in.) |

Maximum Oil Clearance:

|

Item |

Specified Condition |

|---|---|

|

Intake Side |

0.080 mm (0.00315 in.) |

|

Exhaust Side |

0.10 mm (0.00394 in.) |

HINT:

- Oil clearance = Valve guide bush inside diameter - Valve stem diameter

- If the oil clearance is more than the maximum, replace the valve and valve guide bush.

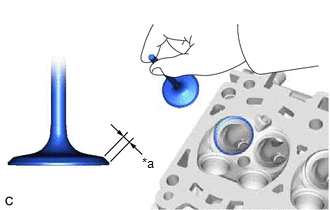

6. INSPECT INTAKE VALVE SEAT

(a) Apply a light coat of Prussian blue to the valve face.

|

(b) Lightly press the valve face against the intake valve seat. NOTICE: Do not rotate the valve while pressing it. |

|

(c) Check the valve face and intake valve seat by using the following procedure:

(1) If Prussian blue appears 360° around the entire intake valve face, the valve face is concentric.

HINT:

If the valve face is not concentric, replace the intake valve.

(2) If Prussian blue appears 360° around the entire intake valve seat, the intake valve seat and valve face are concentric.

HINT:

If the valve face is not concentric, replace the cylinder head sub-assembly.

(3) Measure the width of the contact area of the intake valve seat and valve face.

Standard Width:

1.0 to 1.4 mm (0.0394 to 0.0551 in.)

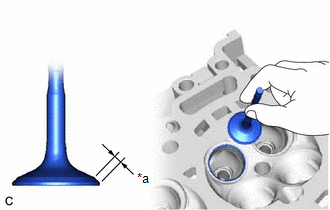

7. INSPECT EXHAUST VALVE SEAT

(a) Apply a light coat of Prussian blue to the valve face.

|

(b) Lightly press the valve face against the exhaust valve seat. NOTICE: Do not rotate the valve while pressing it. |

|

(c) Check the valve face and exhaust valve seat by using the following procedure:

(1) If Prussian blue appears 360° around the entire exhaust valve face, the valve face is concentric.

HINT:

If the valve face is not concentric, replace the exhaust valve.

(2) If Prussian blue appears 360° around the entire exhaust valve seat, the exhaust valve seat and valve face are concentric.

HINT:

If the valve face is not concentric, resurface the exhaust valve seat.

(3) Measure the width of the contact area of the exhaust valve seat and valve face.

Standard Width:

1.3 to 1.7 mm (0.0512 to 0.0669 in.)

8. INSPECT CAMSHAFT THRUST CLEARANCE

(a) Clean the No. 1 camshaft bearing cap, No. 2 camshaft bearing cap, 2 No. 3 camshaft bearing caps, No. 4 camshaft bearing cap, camshaft housing sub-assembly and camshaft journals.

(b) Place the camshaft and No. 2 camshaft on the camshaft housing sub-assembly on the cylinder head sub-assembly.

(c) Install the camshaft bearing caps.

(d) Install the camshaft housing sub-assembly.

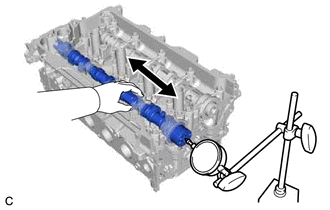

|

(e) Using a dial indicator, measure the thrust clearance while moving the camshaft and No. 2 camshaft back and forth. Standard Thrust Clearance:

Maximum Thrust Clearance:

HINT: If the thrust clearance is more than the maximum, replace the camshaft housing sub-assembly. If the thrust surface is damaged, replace the camshaft. |

|

|

|

|

![2018 - 2019 MY Camry [03/2017 - 09/2019]; A25A-FKS (ENGINE MECHANICAL): ENGINE UNIT: REASSEMBLY+](/t3Portal/stylegraphics/info.gif)