| Last Modified: 09-09-2025 | 6.11:8.1.0 | Doc ID: RM1000000012SY0 |

| Model Year Start: 2018 | Model: Camry | Prod Date Range: [03/2017 - 06/2017] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: VEHICLE STABILITY CONTROL SYSTEM: C1237; Speed Sensor Rotor Faulty; 2018 MY Camry [03/2017 - 06/2017] | ||

|

DTC |

C1237 |

Speed Sensor Rotor Faulty |

DESCRIPTION

The skid control ECU (brake actuator assembly) measures the speed of each wheel by receiving signals from each speed sensor.

These signals are used for recognizing that all four wheels are operating properly.

Therefore, signals from all wheels must be equal.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

C1237 |

Speed Sensor Rotor Faulty |

Any of the following is detected:

|

|

DTC Detection Conditions: C1237

|

Vehicle Condition |

|||||

|---|---|---|---|---|---|

|

Pattern 1 |

Pattern 2 |

Pattern 3 |

Pattern 4 |

||

|

Diagnosis Condition |

- |

- |

- |

- |

- |

|

Malfunction Status |

Discrepancy among four wheel speed sensor output. |

○ |

- |

- |

- |

|

Abnormal pulse signals from 3 or more sensors. |

- |

○ |

- |

- |

|

|

Continuous ABS control is performed. |

- |

- |

○ |

- |

|

|

VSC control is performed. |

- |

- |

- |

○ |

|

|

Detection Time |

- |

- |

60 seconds or more |

5 seconds or more |

|

|

Number of Trips |

1 trip |

1 trip |

1 trip |

1 trip |

|

HINT:

DTC will be output when conditions for either of the patterns in the table above are met.

WIRING DIAGRAM

Refer to DTCs C1330, C1331, C1332, C1333, C1464, C1465, C1466 and C1467.

CAUTION / NOTICE / HINT

NOTICE:

When replacing the skid control ECU (brake actuator assembly), perform system variant learning and acceleration sensor zero point calibration.

HINT:

When C1330, C1331, C1332, C1333, C1464, C1465, C1466 and/or C1467 is output together with C1237, inspect and repair the trouble areas indicated by C1330, C1331, C1332, C1333, C1464, C1465, C1466 and/or C1467 first.

PROCEDURE

PROCEDURE

|

1. |

CHECK DTC |

(a) Check the DTCs that are output.

Chassis > ABS/VSC/TRAC > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

C1237 and C1330, C1331, C1332, C1333, 1464, C1465, C1466, C1467 are output simultaneously |

A |

|

C1237 is output |

B |

| A |

|

GO TO DTCS (C1330, C1331, C1332, C1333, 1464, C1465, C1466 and/or C1467) |

| B |

|

|

2. |

CHECK TIRES |

(a) Check the size and condition of all four tires.

HINT:

The DTC is output when tire deformation or a difference in tire size is detected.

OK:

The diameter and tire pressure of all four tires are the same.

| NG |

|

REPLACE TIRES SO THAT ALL FOUR TIRES ARE THE SAME SIZE |

|

|

3. |

READ VALUE USING TECHSTREAM (SPEED SENSOR) |

(a) Connect the Techstream to the DLC3.

(b) Start the engine.

(c) Enter the following menus: Chassis / ABS/VSC/TRAC / Data List.

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

FR Wheel Speed |

Front wheel speed sensor RH reading |

Min.: 0 km/h (0 mph), Max.: 326.4 km/h (203 mph) |

Vehicle stopped: 0 km/h (0 mph) |

When driving at constant speed: No large fluctuations |

|

FL Wheel Speed |

Front wheel speed sensor LH reading |

Min.: 0 km/h (0 mph), Max.: 326.4 km/h (203 mph) |

Vehicle stopped: 0 km/h (0 mph) |

When driving at constant speed: No large fluctuations |

|

RR Wheel Speed |

Rear wheel speed sensor RH reading |

Min.: 0 km/h (0 mph), Max.: 326.4 km/h (203 mph) |

Vehicle stopped: 0 km/h (0 mph) |

When driving at constant speed: No large fluctuations |

|

RL Wheel Speed |

Rear wheel speed sensor LH reading |

Min.: 0 km/h (0 mph), Max.: 326.4 km/h (203 mph) |

Vehicle stopped: 0 km/h (0 mph) |

When driving at constant speed: No large fluctuations |

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

|---|

|

FR Wheel Speed |

|

FL Wheel Speed |

|

RR Wheel Speed |

|

RL Wheel Speed |

(d) Check the speed sensor output value.

OK:

The output value changes in accordance with the vehicle speed.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (The output value for front speed sensor RH does not change in accordance with the vehicle speed) |

B |

|

NG (The output value for front speed sensor LH does not change in accordance with the vehicle speed) |

C |

|

NG (The output value for rear speed sensor RH (rear axle hub and bearing assembly RH) does not change in accordance with the vehicle speed) |

D |

|

NG (The output value for rear speed sensor LH (rear axle hub and bearing assembly LH) does not change in accordance with the vehicle speed) |

E |

|

NG (The output value of 2 or more sensors does not change in accordance with the vehicle speed) |

F |

| F |

|

| B |

|

| C |

|

| D |

|

| E |

|

|

|

4. |

PERFORM TEST MODE INSPECTION (SIGNAL CHECK) |

(a) Turn the ignition switch off.

(b) Enter the following menus: Chassis / ABS/VSC/TRAC / Utility / Signal Check.

(c) Perform the sensor check using Test Mode (Signal Check) Procedure.

Chassis > ABS/VSC/TRAC > Utility

|

Tester Display |

|---|

|

Signal Check |

OK:

All Test Mode (Signal Check) inspection items change from incomplete to complete.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (The Test Mode (Signal Check) inspection item for front speed sensor RH does not change from incomplete to complete) |

B |

|

NG (The Test Mode (Signal Check) inspection item for front speed sensor LH does not change from incomplete to complete) |

C |

|

NG (The Test Mode (Signal Check) inspection item for rear speed sensor RH (rear axle hub and bearing assembly RH) does not change from incomplete to complete) |

D |

|

NG (The Test Mode (Signal Check) inspection item for rear speed sensor LH (rear axle hub and bearing assembly LH) does not change from incomplete to complete) |

E |

|

NG (The Test Mode (Signal Check) inspection item for 2 or more sensors does not change from incomplete to complete) |

F |

| A |

|

| B |

|

| C |

|

| D |

|

| E |

|

| F |

|

|

5. |

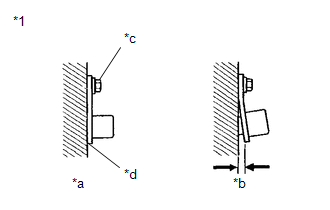

CHECK FRONT SPEED SENSOR RH INSTALLATION |

|

(a) Turn the ignition switch off. |

|

(b) Check the front speed sensor RH installation.

OK:

There is no clearance between the front speed sensor RH and the front steering knuckle RH.

The installation bolt is tightened properly.

Torque

8.5 N*m (87 kgf*cm, 75 in.*lbf)

| NG |

|

|

|

6. |

CHECK FRONT SPEED SENSOR RH (CHECK FOR FOREIGN MATTER) |

(a) Remove the front speed sensor RH.

(b) Check the front speed sensor RH tip.

OK:

The front speed sensor RH tip is free of scratches, oil, and foreign matter.

NOTICE:

| NG |

|

CLEAN OR REPLACE FRONT SPEED SENSOR RH |

|

|

7. |

CHECK FRONT SPEED SENSOR ROTOR RH (CHECK FOR FOREIGN MATTER) |

(a) Remove the front speed sensor rotor RH (front axle hub sub-assembly RH).

(b) Check the front speed sensor rotor RH.

OK:

The front speed sensor rotor RH is free of scratches, oil, and foreign matter.

NOTICE:

HINT:

- The front speed sensor rotor RH is incorporated into the front axle hub sub-assembly RH.

- If the front speed sensor rotor RH needs to be replaced, replace it together with the front axle hub sub-assembly RH.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (The front speed sensor rotor RH is damaged.) |

B |

|

NG (There is foreign matter on the front speed sensor rotor RH.) |

C |

| B |

|

| C |

|

CLEAN FRONT SPEED SENSOR ROTOR RH |

|

|

8. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - FRONT SPEED SENSOR RH) |

(a) Turn the ignition switch off.

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(c) Disconnect the A33 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A33-4 (FR-) - A35-2 (FR-) |

Always |

Below 1 Ω |

|

A33-16 (FR+) - A35-1 (FR+) |

Always |

Below 1 Ω |

|

A33-4 (FR-) or A35-2 (FR-) - Body ground |

Always |

10 kΩ or higher |

|

A33-16 (FR+) or A35-1 (FR+) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

9. |

CHECK FRONT SPEED SENSOR LH INSTALLATION |

|

(a) Turn the ignition switch off. |

|

(b) Check the front speed sensor LH installation.

OK:

There is no clearance between the front speed sensor LH and the front steering knuckle LH.

The installation bolt is tightened properly.

Torque

8.5 N*m (87 kgf*cm, 75 in.*lbf)

| NG |

|

|

|

10. |

CHECK FRONT SPEED SENSOR LH (CHECK FOR FOREIGN MATTER) |

(a) Remove the front speed sensor LH.

(b) Check the front speed sensor LH tip.

OK:

The front speed sensor LH tip is free of scratches, oil, and foreign matter.

NOTICE:

| NG |

|

CLEAN OR REPLACE FRONT SPEED SENSOR LH |

|

|

11. |

CHECK FRONT SPEED SENSOR ROTOR LH (CHECK FOR FOREIGN MATTER) |

(a) Remove the front speed sensor rotor LH (front axle hub sub-assembly LH).

(b) Check the front speed sensor rotor LH.

OK:

The front speed sensor rotor LH is free of scratches, oil, and foreign matter.

NOTICE:

HINT:

- The front speed sensor rotor LH is incorporated into the front axle hub sub-assembly LH.

- If the front speed sensor rotor LH needs to be replaced, replace it together with the front axle hub sub-assembly LH.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (The front speed sensor rotor LH is damaged.) |

B |

|

NG (There is foreign matter on the front speed sensor rotor LH.) |

C |

| B |

|

| C |

|

CLEAN FRONT SPEED SENSOR ROTOR LH |

|

|

12. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - FRONT SPEED SENSOR LH) |

(a) Turn the ignition switch off.

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(c) Disconnect the A33 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A33-8 (FL-) - A36-2 (FL-) |

Always |

Below 1 Ω |

|

A33-19 (FL+) - A36-1 (FL+) |

Always |

Below 1 Ω |

|

A33-8 (FL-) or A36-2 (FL-) - Body ground |

Always |

10 kΩ or higher |

|

A33-19 (FL+) or A36-1 (FL+) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

13. |

CHECK REAR SPEED SENSOR RH INSTALLATION |

|

(a) Turn the ignition switch off. |

|

(b) Check the rear speed sensor RH installation.

OK:

There is no clearance between the rear speed sensor RH and the rear axle hub RH.

HINT:

Because the rear axle hub and bearing assembly RH cannot be disassembled, if the rear speed sensor RH needs replacement, replace the rear axle hub and bearing assembly RH.

| NG |

|

|

|

14. |

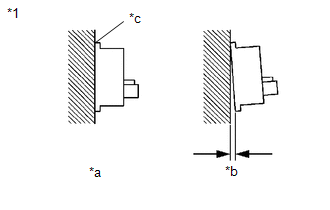

INSPECT SKID CONTROL SENSOR WIRE RH |

|

(a) Turn the ignition switch off. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(c) Remove the skid control sensor wire RH.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

f1-1 (RR-) - fR1-2 (RR-) |

Always |

Below 1 Ω |

|

f1-2 (RR+) - fR1-1 (RR+) |

Always |

Below 1 Ω |

|

f1-1 (RR-) - fR1-1 (RR+) |

Always |

10 kΩ or higher |

|

f1-1 (RR-) or fR1-2 (RR-) - Body ground |

Always |

10 kΩ or higher |

|

f1-2 (RR+) or fR1-1 (RR+) - Body ground |

Always |

10 kΩ or higher |

NOTICE:

Check the rear speed sensor RH signal after replacement.

| NG |

|

REPLACE SKID CONTROL SENSOR WIRE RH |

|

|

15. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - SKID CONTROL SENSOR WIRE RH) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the A33 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A33-29 (RR-) - fR1-2 (RR-) |

Always |

Below 1 Ω |

|

A33-17 (RR+) - fR1-1 (RR+) |

Always |

Below 1 Ω |

|

A33-29 (RR-) or fR1-2 (RR-) - Body ground |

Always |

10 kΩ or higher |

|

A33-17 (RR+) or fR1-1 (RR+) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

16. |

CHECK REAR SPEED SENSOR LH INSTALLATION |

|

(a) Turn the ignition switch off. |

|

(b) Check the rear speed sensor LH installation.

OK:

There is no clearance between the rear speed sensor LH and the rear axle hub LH.

HINT:

Because the rear axle hub and bearing assembly LH cannot be disassembled, if the rear speed sensor LH needs replacement, replace the rear axle hub and bearing assembly LH.

| NG |

|

|

|

17. |

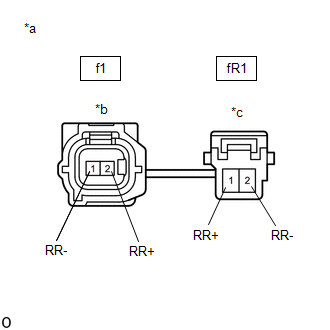

INSPECT SKID CONTROL SENSOR WIRE LH |

|

(a) Turn the ignition switch off. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(c) Remove the skid control sensor wire LH.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

g1-1 (RL-) - gR1-2 (RL-) |

Always |

Below 1 Ω |

|

g1-2 (RL+) - gR1-1 (RL+) |

Always |

Below 1 Ω |

|

g1-1 (RL-) - gR1-1 (RL+) |

Always |

10 kΩ or higher |

|

g1-1 (RL-) or gR1-2 (RL-) - Body ground |

Always |

10 kΩ or higher |

|

g1-2 (RL+) or gR1-1 (RL+) - Body ground |

Always |

10 kΩ or higher |

NOTICE:

Check the rear speed sensor LH signal after replacement.

| NG |

|

REPLACE SKID CONTROL SENSOR WIRE LH |

|

|

18. |

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - SKID CONTROL SENSOR WIRE LH) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the A33 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A33-18 (RL-) - gR1-2 (RL-) |

Always |

Below 1 Ω |

|

A33-31 (RL+) - gR1-1 (RL+) |

Always |

Below 1 Ω |

|

A33-18 (RL-) or gR1-2 (RL-) - Body ground |

Always |

10 kΩ or higher |

|

A33-31 (RL+) or gR1-1 (RL+) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2018 MY Camry [03/2017 - 06/2017]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: VEHICLE STABILITY CONTROL SYSTEM: C1330-C1333,C1464-C1467; Open in Front Speed Sensor RH](/t3Portal/stylegraphics/info.gif)