- DTC judgment completed

- System normal

| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000001DL28 |

| Model Year Start: 2019 | Model: Sienna | Prod Date Range: [08/2018 - ] |

| Title: UA80E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: P07407E; Torque Converter Clutch Actuator Stuck On; 2019 - 2020 MY Sienna [08/2018 - ] | ||

|

DTC |

P07407E |

Torque Converter Clutch Actuator Stuck On |

DESCRIPTION

The ECM uses signals from the throttle position sensor, mass air flow meter, transmission revolution sensor (NT), transmission revolution sensor (NC) and crankshaft position sensor to help determine the engagement timing of the lock-up clutch. The ECM monitors the engagement of the clutch using the transmission revolution sensor (NT), transmission revolution sensor (NC) and crankshaft position sensor.

Then the ECM compares the engagement condition of the lock-up clutch with the lock-up schedule in the ECM memory to detect shift solenoid valve SL, transmission valve body assembly and torque converter assembly mechanical problems.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

Note |

|---|---|---|---|---|---|---|

|

P07407E |

Torque Converter Clutch Actuator Stuck On |

1. Diagnosis Condition, 2. Malfunction Status, 3. Malfunction Time, 4. Other

|

|

Comes on |

DTC stored |

SAE Code: P0741 |

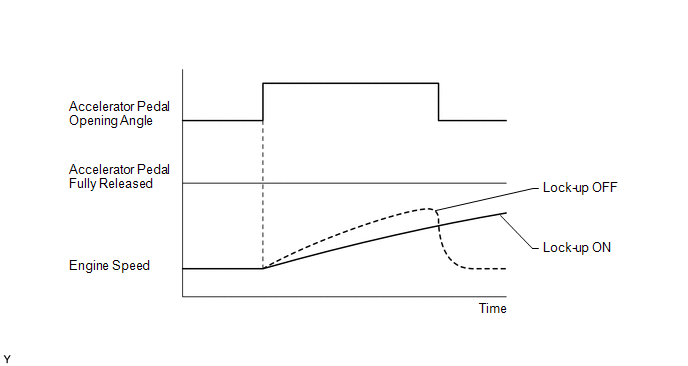

MONITOR DESCRIPTION

Torque converter lock-up is controlled by the ECM based on the transmission revolution sensor (NT), transmission revolution sensor (NC), engine speed, engine load, engine temperature, vehicle speed, transmission fluid temperature, and gear selection. The ECM determines the lock-up status of the torque converter by comparing the engine speed (NE) to the input turbine speed (NT). The ECM calculates the actual transmission gear by comparing the input turbine speed (NT) to the output shaft speed (NC). When conditions are appropriate, the ECM requests "lock-up" by applying control voltage to shift solenoid valve SL. When shift solenoid valve SL is turned on, it applies pressure to the lock-up relay valve and locks the torque converter.

If the ECM detects no lock-up after lock-up has been requested or if it detects lock-up when it is not requested, the ECM interprets this as a fault in shift solenoid valve SL or lock-up system performance. The ECM will illuminate the MIL and store the DTC.

HINT:

Example:

When any of the following is met, the system judges it as a malfunction.

-

There is a difference in rotation speed between the input side (engine speed) and output side (input turbine speed) of the torque converter when the ECM commands lock-up.

(Engine speed is at least 120 rpm more than the input turbine speed.)

-

There is no difference in rotation speed between the input side (engine speed) and output side (input turbine speed) of the torque converter when the ECM commands lock-up off.

(The difference between engine speed and input turbine speed is less than 35 rpm.)

MONITOR STRATEGY

|

Related DTCs |

P0741: Shift solenoid valve SL ON malfunction |

|

Required sensors/Components |

Shift solenoid valve SL, Transmission revolution sensor (NT), Transmission revolution sensor (NC), Crankshaft position sensor (NE), Throttle position sensor (VPA1), Mass air flow meter (MAF), ATF temperature sensor (THO1), Engine coolant temperature sensor (ECT) |

|

Frequency of operation |

Continuous |

|

Duration |

ON malfunction (A): 3.5 sec. ON malfunction (B): 0.5 sec. ON malfunction (C): - |

|

MIL operation |

2 driving cycles |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

All:

|

The monitor will run whenever the following DTCs are not stored present (Not circuit malfunction) (MIL illuminated by following codes) |

P0712, P0713 (TFT (ATF temperature) sensor circuit) P0117, P0118 (ECT (Engine coolant temperature) sensor circuit) P0717, P07BF, P07C0 (Turbine speed sensor circuit) P07C5, P07C6, P0793 (Intermediate Shaft Speed Sensor circuit) P0962, P0963 (Shift solenoid valve SL1 circuit) P0966, P0967 (Shift solenoid valve SL2 circuit) P0970, P0971 (Shift solenoid valve SL3 circuit) P2814, P2815 (Shift solenoid valve SL4 circuit) P281D, P281E (Shift solenoid valve SL5 circuit) P08C1, P08C2 (Shift solenoid valve SL6 circuit) P2764, P2763 (Shift solenoid valve SLU circuit) P2720, P2721 (Shift solenoid valve SLT circuit) P2769, P2770 (Shift solenoid valve SL circuit) P0335, P0337, P0338 (Crankshaft Position Sensor circuit) P0327, P0328, P0332, P0333 (KCS (Knock control sensor) circuit) P0121, P0122, P0123, P0222, P0223, P0604, P0606, P060A, P060B, P060D, P060E, P061E, P0657, P0658, P2102, P2103, P2111, P2112, P2119, P2135 (ETCS (Electronic throttle control system)) U0100 (CAN communication system) |

|

Transmission range |

"D", "not R" and "not N" |

|

Duration time from shifting "N" to "D" |

4 sec. or more |

|

TFT (ATF temperature) |

-10°C (14°F) or higher |

|

Engine |

Running |

ON malfunction (A)

|

Failsafe does not active due to followings malfunction; |

- |

|

Shift solenoid valve SLT (P2714) |

ON malfunction |

|

Shift solenoid valve SLU (P2757) |

OFF or ON malfunction |

|

Shift solenoid valve SL (P0741) |

ON malfunction |

|

ECT (Engine coolant temperature) |

40°C (104°F) or higher |

|

Spark advance from Max. retard timing by KCS control |

0°CA or more |

|

ECM selected gear |

1st, 2nd, 3rd, 4th, 5th, 6th, 7th or 8th |

|

Vehicle speed |

10 km/h (6.2 mph) or more |

|

ECM indicate SL |

OFF |

|

ECM indicate pressure value of SLU |

- |

|

when A/C off |

515 kPa (5.25 kgf/cm2, 74.7 psi) or more |

|

when A/C on |

515 kPa (5.25 kgf/cm2, 74.7 psi) or more |

ON malfunction (B)

|

Fail-safe function does not operate due to the following malfunctions: |

- |

|

Solenoid (SL1) valve |

OFF or ON malfunction (P0746) |

|

Solenoid (SL2) valve |

OFF or ON malfunction (P0776) |

|

Solenoid (SL3) valve |

OFF or ON malfunction (P0796) |

|

Solenoid (SL4) valve |

OFF or ON malfunction (P2808) |

|

Solenoid (SL5) valve |

OFF or ON malfunction (P2817) |

|

Solenoid (SL6) valve |

OFF or ON malfunction (P08BB) |

|

Solenoid (SLT) valve |

OFF malfunction (P2714) |

|

Solenoid (SLU) valve |

ON malfunction (P2757) |

|

Solenoid (SL) valve |

ON malfunction (P0741) |

|

All shift solenoid |

Not being stopped |

|

Neutral command flag |

Not met |

|

Vehicle stop check |

Fixed |

|

ECM selected gear |

3rd, 4th, 6th or 7th |

ON malfunction (C)

|

ECM selected gear |

3rd, 4th, 6th or 7th |

HINT:

Actual gear:

-

1st gear

Any of the following conditions are met

(a) or (b)

(a) Turbine speed / Output speed (NT/NO)

4.7 or more and 9.5 or less

(When output speed less than 50 rpm)

(b) NT-NO x 1st gear ratio

-50 rpm or more and 50 rpm or less

(When output speed 50 rpm or more)

2nd gear

Any of the following conditions are met

(a) or (b)

(a) Turbine speed / Output speed (NT/NO)

2.9 or more and 3.5 or less

(When output speed less than 180 rpm)

(b) NT-NO x 2nd gear ratio

-50 rpm or more and 50 rpm or less

(When output speed 180 rpm or more)

3rd gear

Any of the following conditions are met

(a) or (b)

(a) Turbine speed / Output speed (NT/NO)

1.9 or more and 2.2 or less

(When output speed less than 350 rpm)

(b) NT-NO x 3rd gear ratio

-50 rpm or more and 50 rpm or less

(When output speed 350 rpm or more)

4th gear

Any of the following conditions are met

(a) or (b)

(a) Turbine speed / Output speed (NT/NO)

1.4 or more and 1.581 or less

(When output speed less than 350 rpm)

(b) NT-NO x 4th gear ratio

-50 rpm or more and 50 rpm or less

(When output speed 350 rpm or more)

5th gear

Any of the following conditions are met

(a) or (b)

(a) Turbine speed / Output speed (NT/NO)

1.142 or more and 1.323 or less

(When output speed less than 550 rpm)

(b) NT-NO x 5th gear ratio

-50 rpm or more and 50 rpm or less

(When output speed 550 rpm or more)

6th gear

Any of the following conditions are met

(a) or (b)

(a) Turbine speed / Output speed (NT/NO)

0.934 or more and 1.065 or less

(When output speed less than 750 rpm)

(b) NT-NO x 6th gear ratio

-50 rpm or more and 50 rpm or less

(When output speed 750 rpm or more)

7th gear

Any of the following conditions are met

(a) or (b)

(a) Turbine speed / Output speed (NT/NO)

0.737 or more and 0.867 or less

(When output speed less than 750 rpm)

(b) NT-NO x 7th gear ratio

-50 rpm or more and 50 rpm or less

(When output speed 750 rpm or more)

8th gear

Any of the following conditions are met

(a) or (b)

(a) Turbine speed / Output speed (NT/NO)

0.621 or more and 0.725 or less

(When output speed less than 950 rpm)

(b) NT-NO x 8th gear ratio

-50 rpm or more and 50 rpm or less

(When output speed 950 rpm or more)

Neutral command flag:

|

Engine speed |

7200 rpm or more |

|

Turbine speed |

7200 rpm or more |

-

Any of the following conditions are met: Condition (a) or (b)

-

Condition (a)

ECM selected gear

6th, 7th or 8th

Output speed x 5th gear ratio

7200 rpm or more

Condition (b)

ECM selected gear

4th or 5th

Output speed x 3rd gear ratio

7200 rpm or more

-

Condition (a)

Vehicle stop check:

|

Vehicle speed |

0 km/h (0 mph) or less |

TYPICAL MALFUNCTION THRESHOLDS

Any of the following conditions are met: ON malfunction (A), (B) or (C)

ON malfunction (A):

|

Engine speed - Turbine speed |

120 rpm or more |

ON malfunction (B):

|

Neutral state flag |

ON |

ON malfunction (C):

|

Shift solenoid valve SLT |

ON malfunction |

Neutral state flag:

|

Turbine speed - output speed x (ECM selected gear) |

1000 rpm or more |

CONFIRMATION DRIVING PATTERN

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

- Connect the Techstream to the DLC3.

- Turn the ignition switch to ON and turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

- Turn the ignition switch to ON and turn the Techstream on.

- Start the engine.

-

Perform the Lock-up Function inspection in Road Test. [*1]

HINT:

[*1] : Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Stop the vehicle.

- Enter the following menus: Powertrain / Transmission / Utility / All Readiness.

- Input the DTC: P07407E.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

WIRING DIAGRAM

Refer to DTC P074011.

CAUTION / NOTICE / HINT

NOTICE:

ACTIVE TEST

HINT:

Using the Techstream to perform Active Tests allows relays, VSVs, actuators and other items to be operated without removing any parts. This non-intrusive functional inspection can be very useful because intermittent operation may be discovered before parts or wiring is disturbed. Performing Active Tests early in troubleshooting is one way to save diagnostic time. Data List information can be displayed while performing Active Tests.

(a) Warm up the engine.

(b) Turn the ignition switch off.

(c) Connect the Techstream to the DLC3.

(d) Turn the ignition switch to ON.

(e) Turn the Techstream on.

(f) Enter the following menus: Powertrain / Transmission / Active Test.

(g) According to the display on the Techstream, perform the Active Test.

Transmission

|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Activate the Lock Up Solenoid |

Controls the shift solenoid valves SLU and SL to set the automatic transmission to the lock-up condition. |

ON/OFF |

Can be used to check shift solenoid valves SLU and SL operation. [Vehicle Condition] Vehicle speed: 60 km/h (36 mph) or more |

HINT:

- This test can be conducted when the vehicle speed is 80 km/h (50 mph) or more.

(h) Lightly depress the accelerator pedal and check that the engine speed does not change abruptly.

HINT:

- When changing the accelerator pedal opening angle while driving, if the engine speed does not change, lock-up is on.

- Slowly release the accelerator pedal in order to decelerate, but do not fully release the pedal. (Fully releasing the pedal will close the throttle valve and lock-up may be turned off.)

PROCEDURE

|

1. |

CHECK OTHER DTCS OUTPUT (IN ADDITION TO DTC P07407E) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Transmission / Trouble Codes.

(e) Read the DTCs using the Techstream.

|

Result |

Proceed to |

|---|---|

|

Only DTC P07407E is output |

A |

|

P07407E and other DTCs are output |

B |

HINT:

If any other codes besides P07407E are output, perform the troubleshooting for those DTCs first.

| B |

|

|

|

2. |

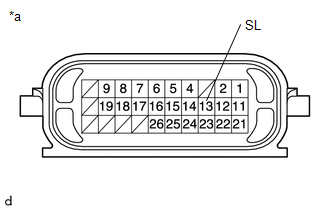

INSPECT TRANSMISSION WIRE (SHIFT SOLENOID VALVE SL) |

|

(a) Disconnect the B65 transmission wire connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

13 (SL) - Body ground |

20°C (68°F) |

11 to 15 Ω |

| NG |

|

|

|

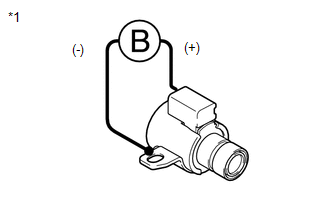

3. |

INSPECT SHIFT SOLENOID VALVE SL (OPERATION) |

|

(a) Remove the shift solenoid valve SL. |

|

(b) Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating sound.

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Valve moves and makes an operating sound |

| NG |

|

|

|

4. |

INSPECT TRANSMISSION VALVE BODY ASSEMBLY |

(a) Check the transmission valve body assembly.

OK:

There is no foreign matter on each valve and they operate smoothly.

| NG |

|

|

|

5. |

INSPECT TORQUE CONVERTER ASSEMBLY |

(a) Check the torque converter assembly.

OK:

The torque converter operates normally.

| OK |

|

| NG |

|

|

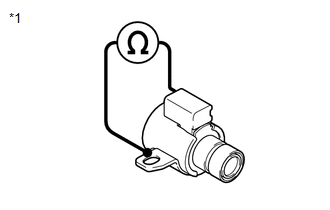

6. |

INSPECT SHIFT SOLENOID VALVE SL (RESISTANCE) |

|

(a) Remove the shift solenoid valve SL. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Shift solenoid valve SL connector terminal - Shift solenoid valve SL body |

20°C (68°F) |

11 to 15 Ω |

| OK |

|

| NG |

|

|

|

|

![2017 - 2020 MY Sienna [08/2016 - ]; UA80E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)