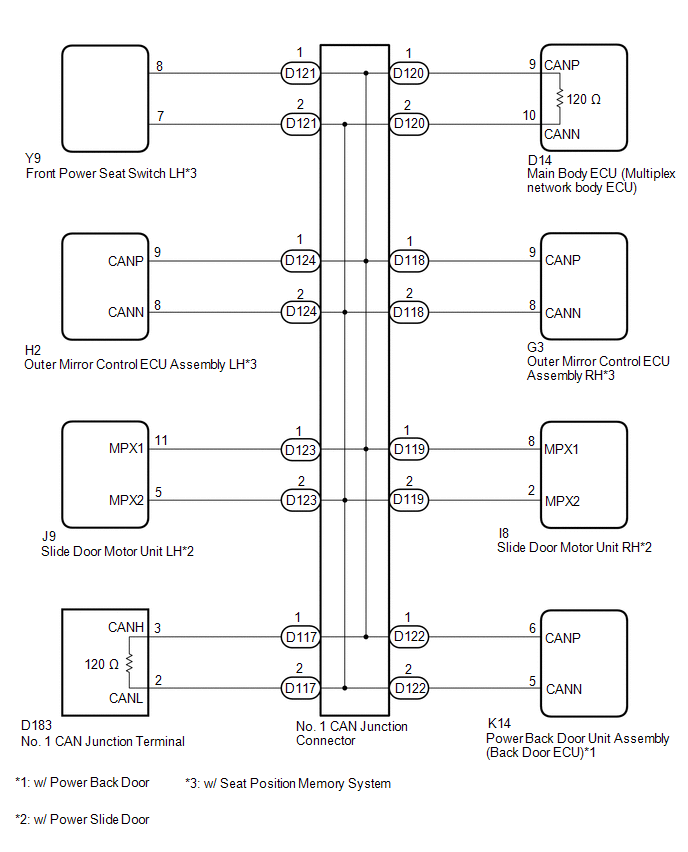

- Sub bus 1 circuit

- Main body ECU (multiplex network body ECU) main wire or connector

- Junction terminal main wire or connector

- Outer mirror control ECU Assembly LH branch wire or connector*1

- Outer mirror control ECU Assembly RH branch wire or connector*1

- Power back door unit assembly (back door ECU) branch wire or connector*2

- Front power seat switch LH branch wire or connector*1

- Slide door motor unit LH branch wire or connector*3

- Slide door motor unit RH branch wire or connector*3

- Main body ECU (multiplex network body ECU)

- No. 1 Junction terminal

- Outer mirror control ECU Assembly LH*1

- Outer mirror control ECU Assembly RH*1

- Power back door unit assembly (back door ECU)*2

- Front power seat switch LH*1

- Slide door motor unit LH*3

- Slide door motor unit RH*3

- Instrument panel junction block assembly

- No. 1 CAN junction connector

| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM1000000018DNX |

| Model Year Start: 2018 | Model: Sienna | Prod Date Range: [11/2017 - 08/2018] |

| Title: NETWORKING: CAN COMMUNICATION SYSTEM: U1002; Lost Communication with Gateway Module; 2018 MY Sienna [11/2017 - 08/2018] | ||

|

DTC |

U1002 |

Lost Communication with Gateway Module |

DESCRIPTION

If 2 or more DTCs are output during the DTC check, one side of the CAN branch wire may be open (One side of the CANH (branch wire)/CANL (branch wire) of the ECU and/or sensor is open).

|

DTC Code |

Symptom |

Trouble Area |

|---|---|---|

|

U1002 |

Lost communication with the gateway module (main body ECU). |

|

- *1: w/ Seat Position Memory System

- *2: w/ Power Back Door

- *3: w/ Power Slide Door

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

NOTICE:

- Because the order of diagnosis is important to allow correct diagnosis, make sure to begin troubleshooting using How to Proceed with Troubleshooting when CAN communication system related DTCs are output.

- Before measuring the resistance of the CAN bus, turn the engine switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

- After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

- Some parts must be initialized and set when replacing or removing and installing parts.

-

After performing repairs, perform the DTC check procedure and confirm that the DTCs are not output again.

DTC check procedure: Turn the ignition switch to ON and wait for 1 minute or more. Then operate the suspected malfunctioning system and drive the vehicle at 60 km/h (37 mph) or more for 5 minutes or more.

- After the repair, perform the CAN bus check and check that all the ECUs and sensors connected to the CAN communication system are displayed as normal.

HINT:

- Before disconnecting related connectors for inspection, push in on each connector body to check that the connector is not loose or disconnected.

- When a connector is disconnected, check that the terminals and connector body are not cracked, deformed or corroded.

PROCEDURE

|

1. |

CHECK CAN BUS WIRE (MAIN WIRE FOR DISCONNECTION, BUS LINE FOR SHORT CIRCUIT) |

(a) Disconnect the cable from the negative (-) battery terminal.

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

Text in Illustration

Result

|

|

| B |

|

| C |

|

|

|

2. |

CHECK FOR OPEN IN MAIN BUS WIRE (NO. 1 CAN JUNCTION CONNECTOR - MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

|

(a) Disconnect the No. 1 CAN junction connector connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

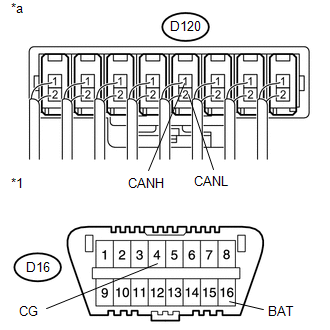

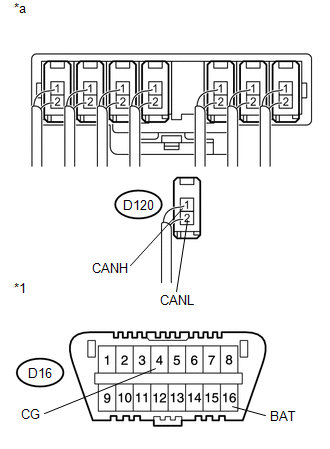

D120-1 (CANH) - D120-2 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

Text in Illustration

|

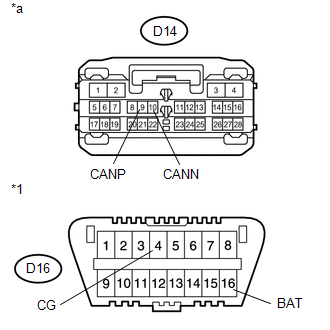

*a |

Rear view of wire harness connector (to No. 1 CAN Junction Connector) |

| NG |

|

|

|

3. |

CHECK FOR OPEN IN CAN BUS MAIN WIRE (NO. 1 CAN JUNCTION CONNECTOR - NO. 1 CAN JUNCTION TERMINAL) |

|

(a) Disconnect the No. 1 CAN junction connector connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

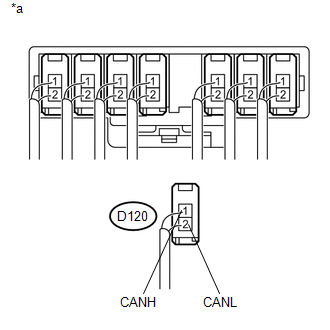

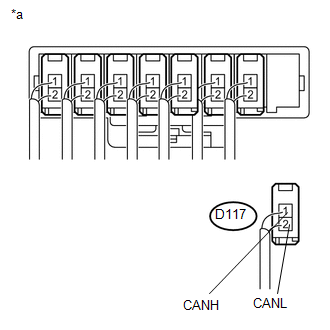

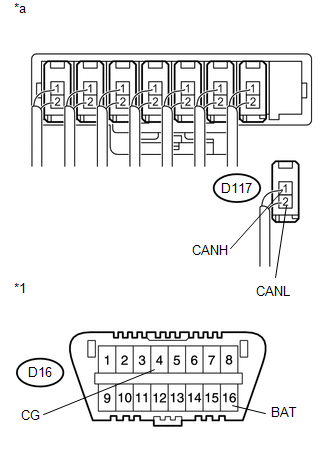

D117-1 (CANH) - D117-2 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

Text in Illustration

|

*a |

Rear view of wire harness connector (to No. 1 CAN Junction Connector) |

| OK |

|

REPAIR OR REPLACE NO. 1 CAN JUNCTION CONNECTOR |

| NG |

|

|

4. |

CONNECT CONNECTOR |

(a) Reconnect the D120 No. 1 CAN junction connector connector.

|

|

5. |

CHECK FOR OPEN IN CAN BUS MAIN WIRE (MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) - NO. 1 CAN JUNCTION CONNECTOR) |

|

(a) Disconnect the main body ECU (multiplex network body ECU) connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

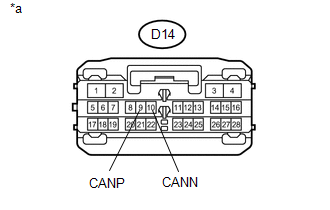

D14-9 (CANP) - D14-10 (CANN) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

Text in Illustration

|

*a |

Front view of wire harness connector (to Main Body ECU (Multiplex Network Body ECU)) |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE CONNECTED TO MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

|

6. |

CONNECT CONNECTOR |

(a) Reconnect the D117 and D120 No. 1 CAN junction connector connectors.

|

|

7. |

CHECK FOR OPEN IN CAN BUS MAIN WIRE (NO. 1 CAN JUNCTION TERMINAL - NO. 1 CAN JUNCTION CONNECTOR) |

|

(a) Disconnect the No. 1 CAN junction terminal connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

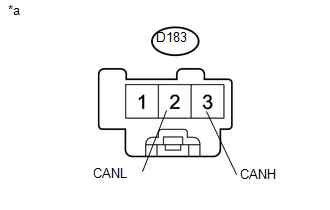

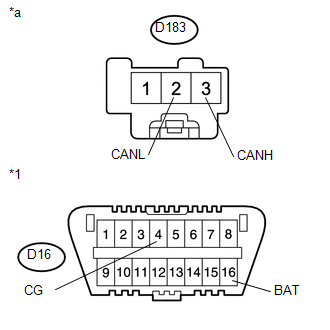

D183-3 (CANH) - D183-2 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

Text in Illustration

|

*a |

Front view of wire harness connector (to No. 1 CAN Junction Terminal) |

| OK |

|

REPLACE NO. 1 CAN JUNCTION TERMINAL |

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE CONNECTED TO NO. 1 CAN JUNCTION TERMINAL |

|

8. |

CHECK FOR SHORT IN CAN BUS WIRES (NO. 1 CAN JUNCTION CONNECTOR - NO. 1 CAN JUNCTION TERMINAL) |

|

(a) Disconnect the No. 1 CAN junction connector connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D117-1 (CANH) - D117-2 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

|

D117-1 (CANH) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D117-2 (CANL) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D117-1 (CANH) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

D117-2 (CANL) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Rear view of wire harness connector (to No. 1 CAN Junction Connector) |

| NG |

|

|

|

9. |

CONNECT CONNECTOR |

(a) Reconnect the D117 No. 1 CAN junction connector connector.

|

|

10. |

CHECK FOR SHORT IN CAN BUS WIRES (NO. 1 CAN JUNCTION CONNECTOR - OUTER MIRROR CONTROL ECU ASSEMBLY RH) |

HINT:

For vehicle without seat position memory system, go to step 14.

|

(a) Disconnect the No. 1 CAN junction connector connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

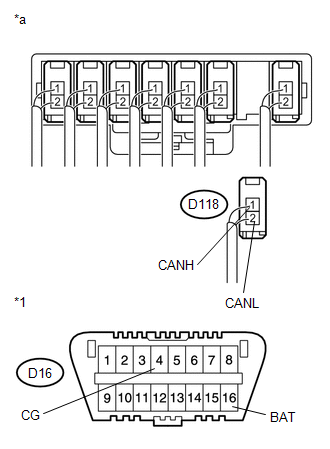

D118-1 (CANH) - D118-2 (CANL) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D118-1 (CANH) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D118-2 (CANL) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D118-1 (CANH) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

D118-2 (CANL) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Rear view of wire harness connector (to No. 1 CAN Junction Connector) |

| NG |

|

|

|

11. |

CONNECT CONNECTOR |

(a) Reconnect the D118 No. 1 CAN junction connector connector.

|

|

12. |

CHECK FOR SHORT IN CAN BUS WIRES (NO. 1 CAN JUNCTION CONNECTOR - SLIDE DOOR MOTOR UNIT RH) |

HINT:

For vehicle without power slide door, go to step 16.

|

(a) Disconnect the No. 1 CAN junction connector connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

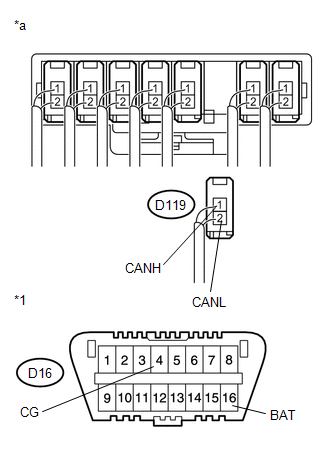

D119-1 (CANH) - D119-2 (CANL) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D119-1 (CANH) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D119-2 (CANL) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D119-1 (CANH) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

D119-2 (CANL) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Rear view of wire harness connector (to No. 1 CAN Junction Connector) |

| NG |

|

|

|

13. |

CONNECT CONNECTOR |

(a) Reconnect the D119 No. 1 CAN junction connector connector.

|

|

14. |

CHECK FOR SHORT IN CAN BUS WIRES (NO. 1 CAN JUNCTION CONNECTOR - FRONT POWER SEAT SWITCH LH) |

HINT:

For vehicle without seat position memory system, go to step 18.

|

(a) Disconnect the No. 1 CAN junction connector connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

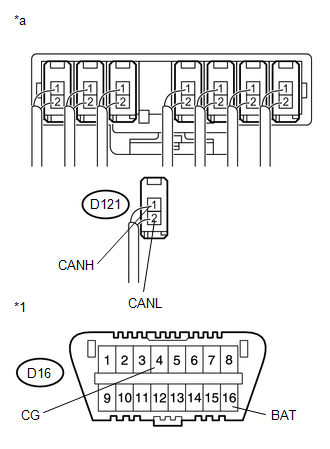

D121-1 (CANH) - D121-2 (CANL) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D121-1 (CANH) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D121-2 (CANL) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D121-1 (CANH) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

D121-2 (CANL) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Rear view of wire harness connector (to No. 1 CAN Junction Connector) |

| NG |

|

|

|

15. |

CONNECT CONNECTOR |

(a) Reconnect the D121 No. 1 CAN junction connector connector.

|

|

16. |

CHECK FOR SHORT IN CAN BUS WIRES (NO. 1 CAN JUNCTION CONNECTOR - POWER BACK DOOR UNIT ASSEMBLY (BACK DOOR ECU)) |

HINT:

For vehicle without power back door, go to step 20.

|

(a) Disconnect the No. 1 CAN junction connector connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

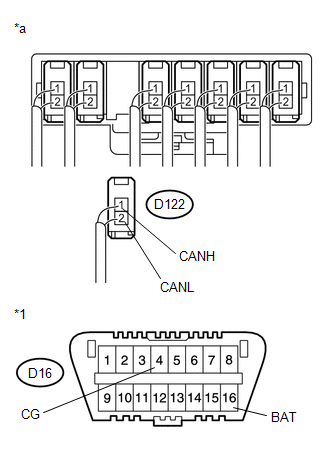

D122-1 (CANH) - D122-2 (CANL) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D122-1 (CANH) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D122-2 (CANL) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D122-1 (CANH) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

D122-2 (CANL) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Rear view of wire harness connector (to No. 1 CAN Junction Connector) |

| NG |

|

|

|

17. |

CONNECT CONNECTOR |

(a) Reconnect the D122 No. 1 CAN junction connector connector.

|

|

18. |

CHECK FOR SHORT IN CAN BUS WIRES (NO. 1 CAN JUNCTION CONNECTOR - SLIDE DOOR MOTOR UNIT LH) |

HINT:

For vehicle without power slide door, go to step 22.

|

(a) Disconnect the No. 1 CAN junction connector connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

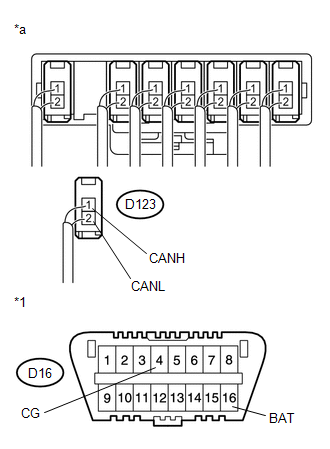

D123-1 (CANH) - D123-2 (CANL) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D123-1 (CANH) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D123-2 (CANL) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D123-1 (CANH) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

D123-2 (CANL) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Rear view of wire harness connector (to No. 1 CAN Junction Connector) |

| NG |

|

|

|

19. |

CONNECT CONNECTOR |

(a) Reconnect the D123 No. 1 CAN junction connector connector.

|

|

20. |

CHECK FOR SHORT IN CAN BUS WIRES (NO. 1 CAN JUNCTION CONNECTOR - OUTER MIRROR CONTROL ECU ASSEMBLY LH) |

HINT:

For vehicle without seat position memory system, go to step 24.

|

(a) Disconnect the No. 1 CAN junction connector connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

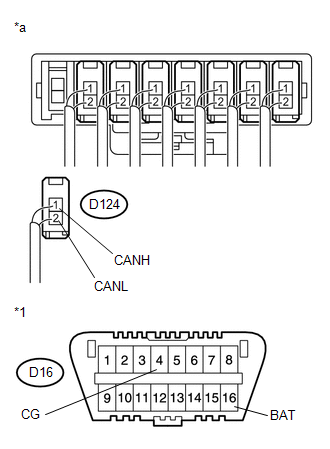

D124-1 (CANH) - D124-2 (CANL) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D124-1 (CANH) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D124-2 (CANL) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D124-1 (CANH) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

D124-2 (CANL) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Rear view of wire harness connector (to No. 1 CAN Junction Connector) |

| NG |

|

|

|

21. |

CONNECT CONNECTOR |

(a) Reconnect the D124 No. 1 CAN junction connector connector.

|

|

22. |

CHECK FOR SHORT IN CAN BUS WIRES (NO. 1 CAN JUNCTION CONNECTOR - MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

|

(a) Disconnect the No. 1 CAN junction connector connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D120-1 (CANH) - D120-2 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

|

D120-1 (CANH) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D120-2 (CANL) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D120-1 (CANH) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

D120-2 (CANL) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Rear view of wire harness connector (to No. 1 CAN Junction Connector) |

| OK |

|

REPAIR OR REPLACE NO. 1 CAN JUNCTION CONNECTOR |

| NG |

|

|

23. |

CONNECT CONNECTOR |

(a) Reconnect the D117 No. 1 CAN junction connector connector.

|

|

24. |

CHECK FOR SHORT IN CAN BUS WIRES (NO. 1 CAN JUNCTION TERMINAL) |

|

(a) Disconnect the No. 1 CAN junction terminal connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D183-3 (CANH) - D183-2 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

|

D183-3 (CANH) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D183-2 (CANL) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D183-3 (CANH) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

D183-2 (CANL) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Front view of wire harness connector (to No. 1 CAN Junction Terminal) |

| OK |

|

REPLACE NO. 1 CAN JUNCTION TERMINAL |

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE CONNECTED TO NO. 1 CAN JUNCTION TERMINAL (CAN-H, CAN-L) |

|

25. |

CONNECT CONNECTOR |

(a) Reconnect the D118 No. 1 CAN junction connector connector.

|

|

26. |

CHECK FOR SHORT IN CAN BUS WIRES (OUTER MIRROR CONTROL ECU ASSEMBLY RH) |

|

(a) Disconnect the outer mirror control ECU assembly RH connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

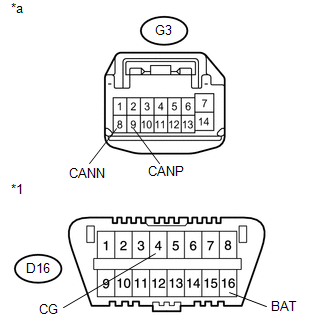

G3-9 (CANP) - G3-8 (CANN) |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

|

G3-9 (CANP) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

G3-8 (CANN) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

G3-9 (CANP) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

G3-8 (CANN) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Front view of wire harness connector (to Outer Mirror Control ECU Assembly RH) |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN BRANCH WIRE CONNECTED TO OUTER MIRROR CONTROL ECU ASSEMBLY RH (CAN-H, CAN-L) |

|

27. |

CONNECT CONNECTOR |

(a) Reconnect the D119 No. 1 CAN junction connector connector.

|

|

28. |

CHECK FOR SHORT IN CAN BUS WIRES (SLIDE DOOR MOTOR UNIT RH) |

|

(a) Disconnect the slide door motor unit RH connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

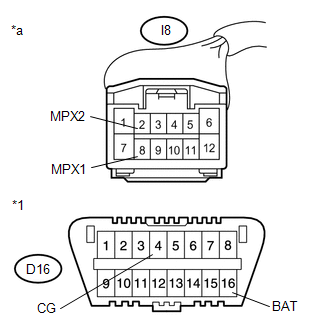

I8-8 (MPX1) - I8-2 (MPX2) |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

|

I8-8 (MPX1) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

I8-2 (MPX2) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

I8-8 (MPX1) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

I8-2 (MPX2) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Front view of wire harness connector (to Slide Door Motor Unit RH) |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN BRANCH WIRE CONNECTED TO SLIDE DOOR MOTOR UNIT RH (CAN-H, CAN-L) |

|

29. |

CONNECT CONNECTOR |

(a) Reconnect the D121 No. 1 CAN junction connector connector.

|

|

30. |

CHECK FOR SHORT IN CAN BUS WIRES (FRONT POWER SEAT SWITCH LH) |

|

(a) Disconnect the front power seat switch LH connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

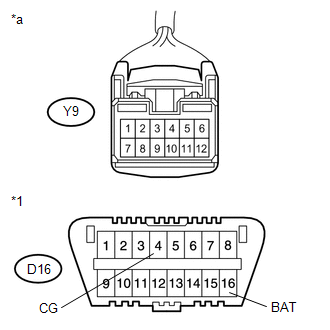

Y9-8 - Y9-7 |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

|

Y9-8 - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

Y9-7 - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

Y9-8 - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

Y9-7 - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Front view of wire harness connector (to Front Power Seat Switch LH) |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN BRANCH WIRE CONNECTED TO FRONT POWER SEAT SWITCH LH (CAN-H, CAN-L) |

|

31. |

CONNECT CONNECTOR |

(a) Reconnect the D122 No. 1 CAN junction connector connector.

|

|

32. |

CHECK FOR SHORT IN CAN BUS WIRES (POWER BACK DOOR UNIT ASSEMBLY (BACK DOOR ECU)) |

|

(a) Disconnect the power back door unit assembly (back door ECU) connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

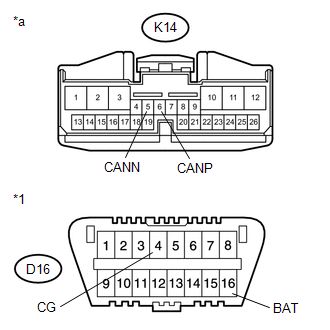

K14-6 (CANP) - K14-5 (CANN) |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

|

K14-6 (CANP) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

K14-5 (CANN) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

K14-6 (CANP) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

K14-5 (CANN) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Front view of wire harness connector (to Power Back Door Unit Assembly (Back Door ECU)) |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN BRANCH WIRE CONNECTED TO POWER BACK DOOR UNIT ASSEMBLY (BACK DOOR ECU) (CAN-H, CAN-L) |

|

33. |

CONNECT CONNECTOR |

(a) Reconnect the D123 No. 1 CAN junction connector connector.

|

|

34. |

CHECK FOR SHORT IN CAN BUS WIRES (SLIDE DOOR MOTOR UNIT LH) |

|

(a) Disconnect the slide door motor unit LH connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

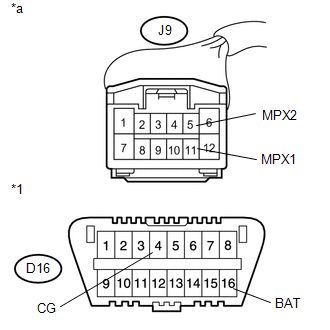

J9-11 (MPX1) - J9-5 (MPX2) |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

|

J9-11 (MPX1) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

J9-5 (MPX2) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

J9-11 (MPX1) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

J9-5 (MPX2) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Front view of wire harness connector (to Slide Door Motor Unit LH) |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN BRANCH WIRE CONNECTED TO SLIDE DOOR MOTOR UNIT LH (CAN-H, CAN-L) |

|

35. |

CONNECT CONNECTOR |

(a) Reconnect the D124 No. 1 CAN junction connector connector.

|

|

36. |

CHECK FOR SHORT IN CAN BUS WIRES (OUTER MIRROR CONTROL ECU ASSEMBLY LH) |

|

(a) Disconnect the outer mirror control ECU assembly LH connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

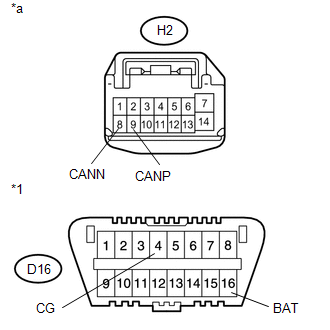

H2-9 (CANP) - H2-8 (CANN) |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

|

H2-9 (CANP) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

H2-8 (CANN) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

H2-9 (CANP) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

H2-8 (CANN) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Front view of wire harness connector (to Outer Mirror Control ECU Assembly LH) |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN BRANCH WIRE CONNECTED TO OUTER MIRROR CONTROL ECU ASSEMBLY LH (CAN-H, CAN-L) |

|

37. |

CONNECT CONNECTOR |

(a) Reconnect the D120 No. 1 CAN junction connector connector.

|

|

38. |

CHECK FOR SHORT IN CAN BUS WIRES (MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

|

(a) Disconnect the main body ECU (multiplex network body ECU) connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D14-9 (CANP) - D14-10 (CANN) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

|

D14-9 (CANP) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D14-10 (CANN) - D16-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

D14-9 (CANP) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

D14-10 (CANN) - D16-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Text in Illustration

|

*1 |

DLC3 |

|

*a |

Front view of wire harness connector (to Main Body ECU (Multiplex Network Body ECU)) |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE CONNECTED TO MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) (CAN-H, CAN-L) |

|

39. |

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY - POWER SOURCE) |

|

(a) Disconnect the instrument panel junction block assembly connectors. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2D-28 - Body ground |

Cable disconnected from negative (-) battery terminal |

Below 1 Ω |

(c) Reconnect the cable to the negative (-) battery terminal.

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected (See page

![2018 - 2020 MY Sienna [11/2017 - ]; INTRODUCTION: REPAIR INSTRUCTION: INITIALIZATION](/t3Portal/stylegraphics/info.gif) ).

).

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2K-1 - Body ground |

Always |

11 to 14 V |

Text in Illustration

|

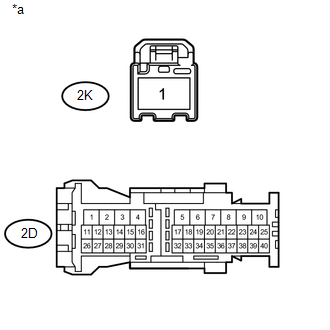

*a |

Front view of wire harness connector (to Instrument Panel Junction Block Assembly) |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

40. |

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

(a) Remove the instrument panel junction block assembly (See page

![2016 - 2020 MY Sienna [12/2015 - ]; POWER DISTRIBUTION: MAIN BODY ECU: REMOVAL](/t3Portal/stylegraphics/info.gif) ).

).

(b) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly (See page

![2016 - 2020 MY Sienna [12/2015 - ]; POWER DISTRIBUTION: MAIN BODY ECU: REMOVAL](/t3Portal/stylegraphics/info.gif) ).

).

(c) Measure the resistance according to the value(s) in the table below.

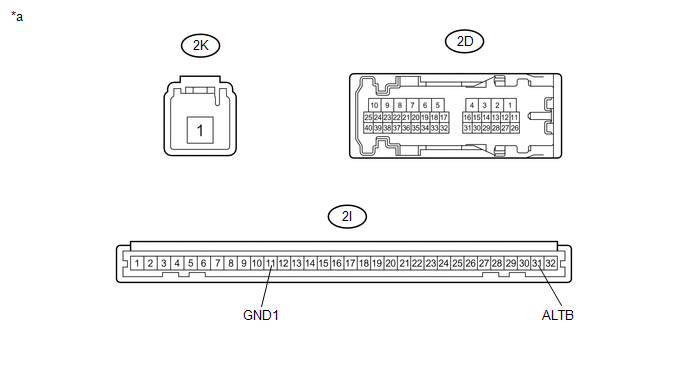

Text in Illustration

|

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

- |

- |

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2K-1 - 2I-31 (ALTB) |

Always |

Below 1 Ω |

|

2D-28 - 2I-11 (GND1) |

Always |

Below 1 Ω |

| OK |

|

| NG |

|

|

|

|