| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000ZQO4 |

| Model Year Start: 2017 | Model: Sienna | Prod Date Range: [08/2016 - 11/2017] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: VEHICLE STABILITY CONTROL SYSTEM: Brake Warning Light Remains ON; 2017 MY Sienna [08/2016 - 11/2017] | ||

|

Brake Warning Light Remains ON |

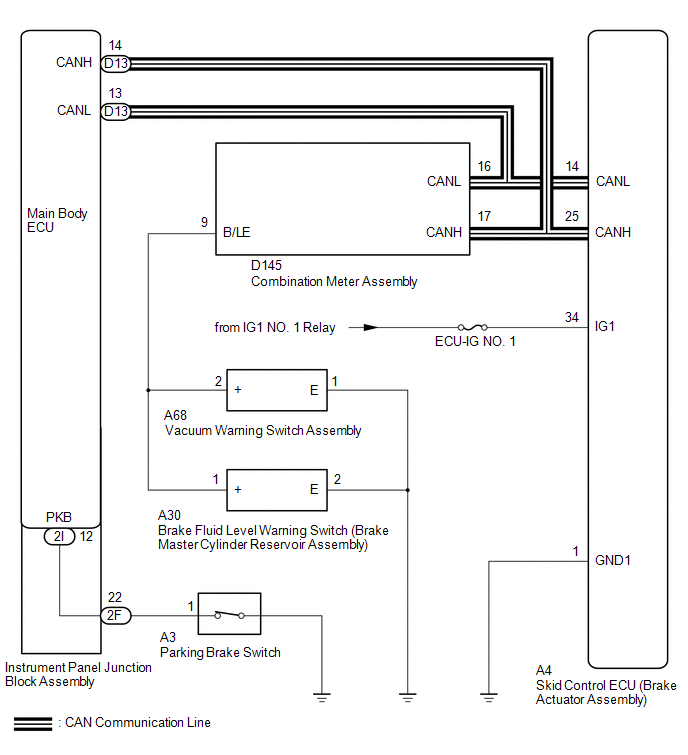

DESCRIPTION

The skid control ECU is connected to the combination meter via CAN communication.

If any of the following is detected, the brake warning light remains on:

- The skid control ECU connector is disconnected from the skid control ECU.

- The brake fluid level is insufficient.

- The parking brake is applied.

- EBD operation has been disabled.

- The vacuum inside the brake booster decreases.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

When replacing the brake actuator assembly, perform zero point calibration and store system information (See page

![2016 - 2017 MY Sienna [12/2015 - 11/2017]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: VEHICLE STABILITY CONTROL SYSTEM: CALIBRATION](/t3Portal/stylegraphics/info.gif) ).

).

PROCEDURE

|

1. |

CHECK CAN COMMUNICATION SYSTEM |

(a) Check if a CAN communication system DTC is output (See page

![2017 MY Sienna [08/2016 - 11/2017]; NETWORKING: CAN COMMUNICATION SYSTEM: DIAGNOSIS SYSTEM](/t3Portal/stylegraphics/info.gif) ).

).

Result

|

Result |

Proceed to |

|---|---|

|

DTC is not output |

A |

|

DTC is output |

B |

| B |

|

|

|

2. |

CHECK IF SKID CONTROL ECU CONNECTOR IS SECURELY CONNECTED |

(a) Check if the skid control ECU connector is securely connected.

OK:

The connector is securely connected.

| NG |

|

CONNECT CONNECTOR TO ECU CORRECTLY |

|

|

3. |

INSPECT BATTERY |

(a) Check the battery voltage.

Standard voltage:

11 to 14 V

| NG |

|

|

|

4. |

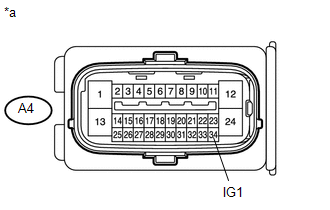

INSPECT SKID CONTROL ECU (IG1 TERMINAL) |

|

(a) Disconnect the skid control ECU connector. |

|

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

A4-34 (IG1) - Body ground |

Ignition switch ON |

11 to 14 V |

Text in Illustration

|

*a |

Front view of wire harness connector (to Skid Control ECU) |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (IG1 CIRCUIT) |

|

|

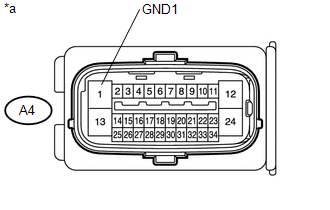

5. |

INSPECT SKID CONTROL ECU (GND1 TERMINAL) |

|

(a) Turn the ignition switch off. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A4-1 (GND1) - Body ground |

Always |

Below 1 Ω |

Text in Illustration

|

*a |

Front view of wire harness connector (to Skid Control ECU) |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (GND1 CIRCUIT) |

|

|

6. |

READ VALUE USING TECHSTREAM (PARKING BRAKE SWITCH) |

(a) Reconnect the skid control ECU connector.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the Techstream on.

(e) Enter the following menus: Chassis / ABS/VSC/ TRAC / Data List.

(f) Select the Data List on the Techstream (See page

![2017 MY Sienna [08/2016 - 11/2017]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: VEHICLE STABILITY CONTROL SYSTEM: DATA LIST / ACTIVE TEST](/t3Portal/stylegraphics/info.gif) ).

).

ABS/VSC/TRAC

|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

Parking Brake SW |

Parking brake switch / ON or OFF |

ON: Parking brake applied OFF: Parking brake released |

- |

(g) Using the Techstream, check the switch condition on the Techstream changes according to parking brake pedal operation.

OK:

The Techstream displays ON or OFF according to parking brake pedal operation.

| NG |

|

|

|

7. |

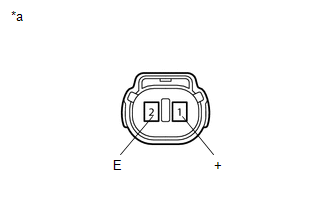

INSPECT BRAKE FLUID LEVEL WARNING SWITCH |

|

(a) Turn the ignition switch off. |

|

(b) Remove the reservoir filler cap and strainer.

(c) Disconnect the brake fluid level warning switch connector.

(d) Measure the resistance according to the value(s) in the table below.

HINT:

A float is located inside the reservoir. Its position can be changed by increasing or decreasing the level of brake fluid.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

1 (+) - 2 (E) |

Brake fluid level warning switch OFF (Float up) |

1.9 to 2.1 kΩ |

|

1 (+) - 2 (E) |

Brake fluid level warning switch ON (Float down) |

Below 1 Ω |

HINT:

If there is no problem after finishing the above check, adjust the brake fluid level to the MAX level.

Text in Illustration

|

*a |

Component without harness connected (Brake Fluid Level Warning Switch) |

| NG |

|

REPLACE BRAKE MASTER CYLINDER RESERVOIR ASSEMBLY (BRAKE FLUID LEVEL WARNING SWITCH) |

|

|

8. |

INSPECT VACUUM WARNING SWITCH ASSEMBLY |

(a) Inspect the vacuum warning switch assembly.

OK:

The vacuum warning switch assembly is normal.

| NG |

|

|

|

9. |

CHECK HARNESS AND CONNECTOR (BRAKE WARNING LIGHT CIRCUIT) |

(a) Disconnect the combination meter connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D145-9 (B/LE) - A30-1 (+) |

Always |

Below 1 Ω |

|

D145-9 (B/LE) - Body ground |

Always |

10 kΩ or higher |

|

A30-2 (E) - Body ground |

Always |

Below 1 Ω |

|

D145-9 (B/LE) - A68-2 (+) |

Always |

Below 1 Ω |

|

A68-1 (E) - Body ground |

Always |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

10. |

PERFORM ACTIVE TEST USING TECHSTREAM (BRAKE WARNING LIGHT) |

(a) Reconnect the skid control ECU connector.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON.

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / Combination Meter / Active Test.

(f) Select the Active Test on the Techstream.

Combination Meter

|

Tester Display |

Test Part |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Indicat. Lamp Brake |

Brake warning light |

OFF or ON |

Operate with IG ON and the vehicle is stopped. |

(g) Check that the brake warning light on the combination meter turns on or off in accordance with the Techstream operation.

OK:

The brake warning light turns on or off in accordance with the Techstream operation.

HINT:

If troubleshooting has been carried out according to Problem Symptoms Table, refer back to the table and proceed to the next step before replacing the part (See page ).

| OK |

|

| NG |

|

|

11. |

INSPECT PARKING BRAKE SWITCH |

|

(a) Turn the ignition switch off. |

|

(b) Disconnect the parking brake switch connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

1 - Body ground |

Parking brake switch ON (Switch pin free) |

Below 1 Ω |

|

1 - Body ground |

Parking brake switch OFF (Switch pin pushed in) |

10 kΩ or higher |

Text in Illustration

|

*a |

Component without harness connected (Parking Brake Switch) |

| NG |

|

|

|

12. |

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK - PARKING BRAKE SWITCH) |

(a) Disconnect the instrument panel junction block assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2F-22 - A3-1 |

Always |

Below 1 Ω |

|

2F-22 - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

13. |

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK - MAIN BODY ECU) |

(a) Remove the main body ECU from the instrument panel junction block assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2I-12 - 2F-22 |

Always |

Below 1 Ω |

|

2I-12 - Body ground |

Always |

10 kΩ or higher |

HINT:

If troubleshooting has been carried out according to Problem Symptoms Table, refer back to the table and proceed to the next step before replacing the part (See page

![2017 MY Sienna [08/2016 - 11/2017]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: VEHICLE STABILITY CONTROL SYSTEM: PROBLEM SYMPTOMS TABLE](/t3Portal/stylegraphics/info.gif) ).

).

| OK |

|

| NG |

|

REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

|

|

|