| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000YXOS |

| Model Year Start: 2017 | Model: Sienna | Prod Date Range: [08/2016 - ] |

| Title: 2GR-FKS (FUEL): FUEL TANK: INSTALLATION; 2017 - 2020 MY Sienna [08/2016 - ] | ||

INSTALLATION

PROCEDURE

1. INSTALL FUEL TANK BAND

(a) Install the 3 fuel tank bands with the 6 clips.

2. INSTALL FUEL TANK CUSHION

(a) Install the 6 fuel tank cushions.

3. INSTALL NO. 2 FUEL TANK CUSHION

(a) Install the 2 No. 2 fuel tank cushions.

4. INSTALL FUEL TANK SIDE PLATE

(a) Install the fuel tank side plate and fuel tank bracket sub-assembly with the nut and bolt.

Torque:

30 N·m {306 kgf·cm, 22 ft·lbf}

5. INSTALL NO. 1 FUEL SUCTION TUBE SET GASKET

(a) Ensure gasket groove is clean and free of foreign particles.

(b) Install a new gasket onto the fuel tank.

(c) Make sure that the gasket sits in the groove.

6. INSTALL FUEL TANK OVERFILL CHECK VALVE ASSEMBLY

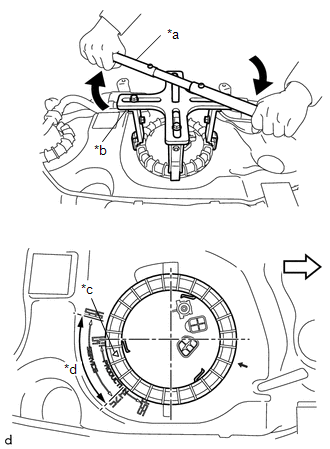

|

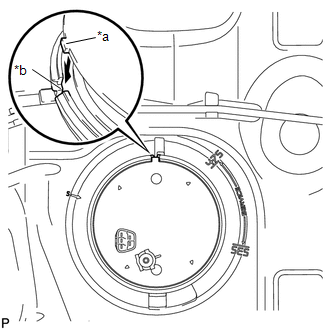

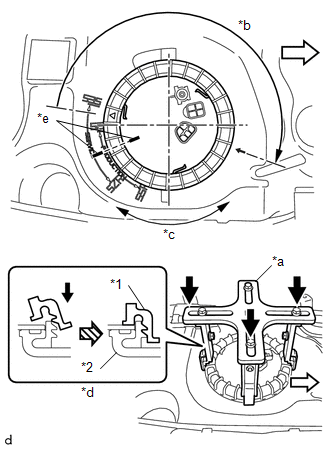

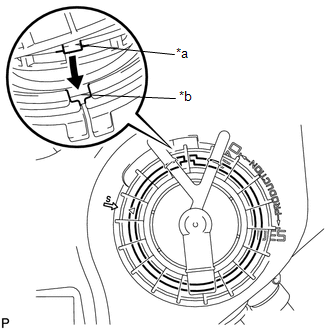

(a) Align the protrusion of the fuel tank overfill check valve assembly with the cutout of the tank suction tube support and install the fuel tank overfill check valve assembly. |

|

|

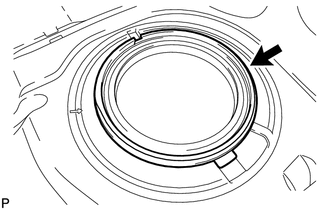

(b) Align marks on the fuel pump gauge retainer and the fuel tank. |

|

(c) Position the fuel pump gauge retainer on top of the fuel tank overfill check valve assembly flange while pushing down the flange on center.

(d) While holding the fuel tank overfill check valve assembly, tighten the fuel pump gauge retainer one complete turn by hand*1.

NOTICE:

- Make sure the fuel tank overfill check valve assembly anti-rotation tab is in the groove during above operation.

- "S" arrow on the fuel tank indicates 0 degrees position.

|

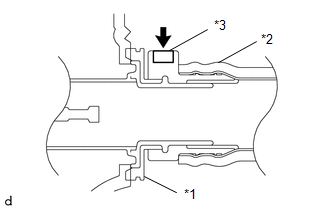

(e) Ensure that no cross threading occurred during installation by checking the gap between the fuel pump gauge retainer and the fuel tank. Confirm that the gap is even. If cross threading occurred, remove the fuel pump gauge retainer and repeat step*1. |

|

(f) Using SST, tighten the fuel pump gauge retainer.

SST: 09808-14031

09808-01080

09808-01090

09808-01100

NOTICE:

- No ratcheting effect allowed when tightening the fuel pump gauge retainer.

- No grease or lubrication allowed on parts during installation.

HINT:

- Align the ribs of the fuel pump gauge retainer with the tips of SST.

(g) Install the fuel pump gauge retainer by one and a half turns so that the start mark on the fuel pump gauge retainer is between 470° and 530° from the start position.

(h) If the start mark does not reach 470°, confirm that no cross threading occurred by measuring the gap between the fuel pump gauge retainer and the fuel tank.

If cross threading occurred, replace the fuel tank overfill check valve assembly, the gasket and the tank suction tube support.

(i) Replace the tank suction tube support.

|

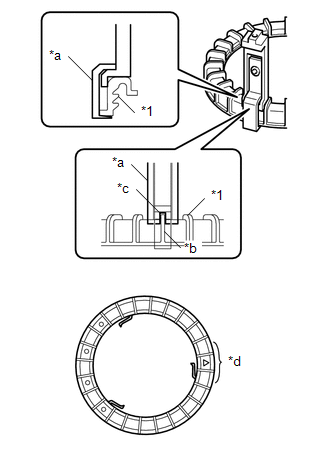

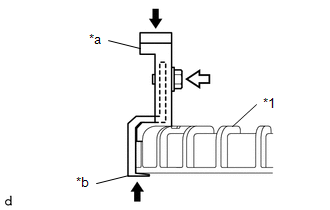

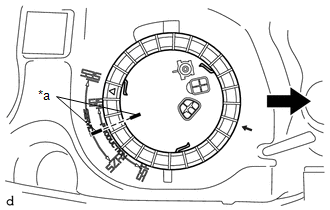

(1) Remove the tank suction tube support from the fuel tank. |

|

|

(2) Install the tank suction tube support to the fuel tank as shown in the illustration. |

|

|

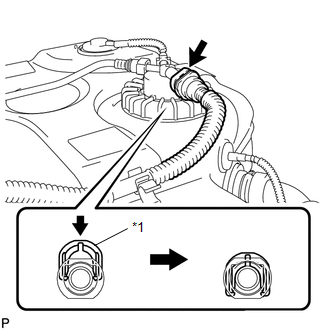

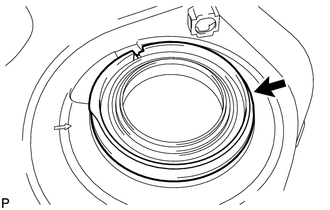

(j) Engage the hose clamp. |

|

|

(k) Put a mark on the fuel pump gauge retainer and the fuel tank with paint. This will be the evidence that the fuel pump gauge retainer has been removed. |

|

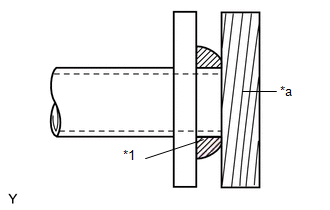

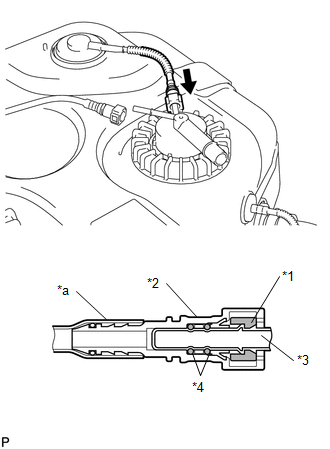

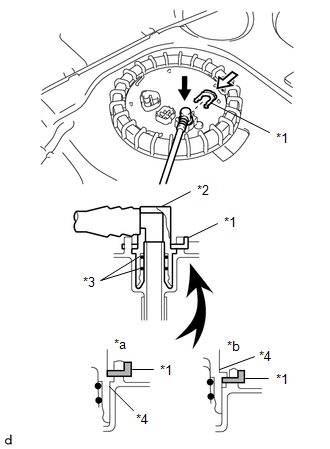

(l) Line up the pipe and connector and push them together until a "click" sound is heard.

|

*1 |

Retainer |

|

*2 |

Fuel Tube Connector |

|

*3 |

Fuel Pipe |

|

*4 |

O-ring |

|

*a |

Nylon Tube |

|

Push |

NOTICE:

- Check that there are no scratches or foreign objects on the connecting part.

- Check that the tube is inserted securely.

- Check that the tube is securely connected by pulling on it.

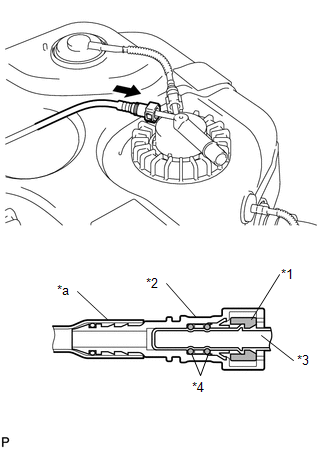

(m) Line up the pipe and connector and push them together until a "click" sound is heard.

|

*1 |

Retainer |

|

*2 |

Fuel Tube Connector |

|

*3 |

Fuel Pipe |

|

*4 |

O-ring |

|

*a |

Nylon Tube |

|

Push |

NOTICE:

- Check that there are no scratches or foreign objects on the connecting part.

- Check that the tube is inserted securely.

- Check that the tube is securely connected by pulling on it.

7. INSTALL FUEL SUCTION TUBE SET GASKET

(a) Ensure gasket groove is clean and free of foreign particles.

(b) Install a new gasket onto the fuel tank.

(c) Make sure that the gasket sits in the groove.

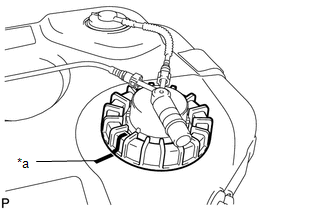

8. INSTALL FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY

|

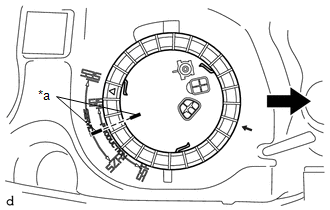

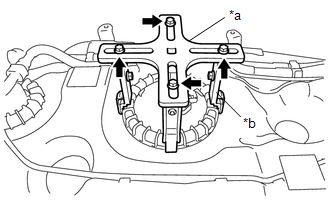

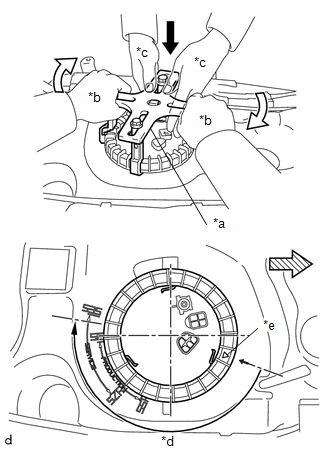

(a) Align the protrusion of the fuel suction with pump and gauge tube assembly with the cutout of the tank suction tube support and install the fuel suction with pump and gauge tube assembly. NOTICE: Do not bend the arm of the fuel sender gauge. |

|

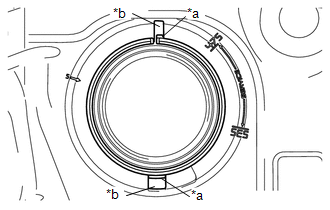

(b) Place a paint mark on the fuel suction tube with pump and gauge assembly as shown in the illustration.

|

*a |

Paint Mark |

|

Front Side of Vehicle |

HINT:

Perform this step only when replacing the fuel suction tube with pump and gauge assembly.

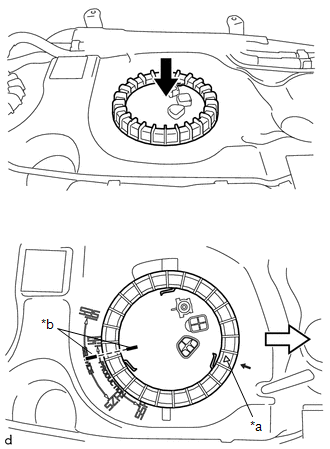

9. INSTALL FUEL PUMP GAUGE RETAINER

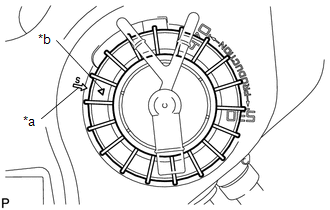

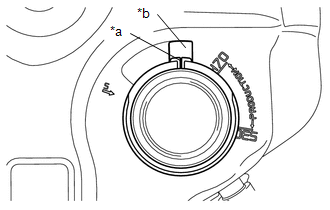

(a) Align the start of the threads of a new fuel pump gauge retainer with the start of threads mark while pushing down the fuel suction tube with pump and gauge assembly, attach the fuel pump gauge retainer.

|

*a |

Start of Threads of the Fuel Pump Gauge Retainer |

|

*b |

Align |

|

Press down |

|

Front Side of Vehicle |

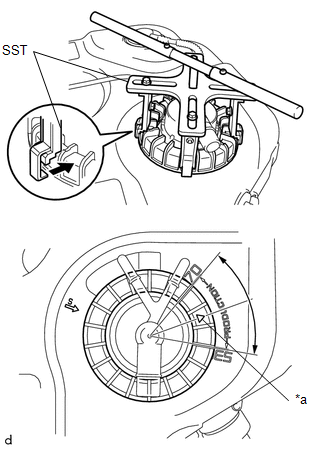

(b) Install SST to the fuel pump gauge retainer.

|

(1) Set 4 SST (claw set) to the fuel pump gauge retainer. SST: 09808-14031 09808-01080 09808-01090 09808-01100 NOTICE:

|

|

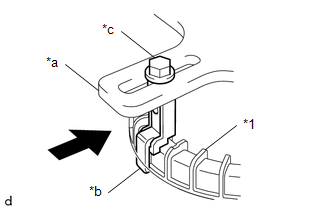

(2) Push SST (claw set) against the fuel pump gauge retainer and tighten SST (bolt).

|

*1 |

Fuel Pump Gauge Retainer |

|

*a |

SST (Claw Set) |

|

*b |

Hook |

|

Push |

|

SST (Bolt) |

(3) Temporarily install SST (plate) to SST (claw set) with 4 SST (bolt).

SST: 09808-14031

09808-01030

09808-01090

|

*a |

SST (Plate) |

|

*b |

SST (Claw Set) |

|

SST (Bolt) |

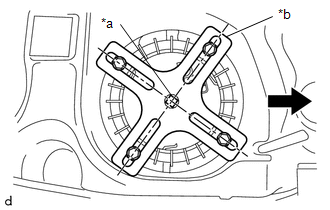

(4) Adjust the position of SST (claw set) so that the hole in SST (plate) for installing SST (handle) is in the center of the fuel pump gauge retainer.

|

*a |

Center Point of Fuel Pump Gauge Retainer |

|

*b |

SST (Plate) |

|

Front Side of Vehicle |

(5) Press SST (claw set) against the rib of the fuel pump gauge retainer and tighten SST (bolt).

|

*1 |

Fuel Pump Gauge Retainer |

|

*a |

SST (Plate) |

|

*b |

SST (Claw Set) |

|

*c |

SST (Bolt) |

|

Press |

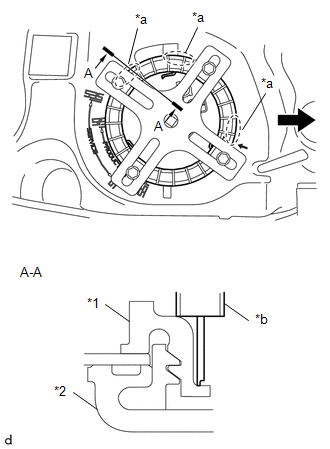

(c) While pressing down on the fuel suction tube with pump and gauge assembly, have another person firmly press the fuel pump gauge retainer against the threads of the fuel tank assembly, and tighten the fuel pump gauge retainer by approximately 180°.

|

*1 |

Fuel Pump Gauge Retainer |

|

*2 |

Fuel Tank Assembly |

|

*a |

SST (Plate) |

|

*b |

Tighten approximately 180° |

|

*c |

Fuel pump gauge retainer rises up |

|

*d |

Cross Section |

|

*e |

Paint Mark |

|

Press quickly and firmly |

|

Front Side of Vehicle |

NOTICE:

- To prevent damage to parts, do not turn SST too vigorously.

- Do not turn the fuel pump gauge retainer if the paint marks become misaligned.

(d) Quickly and firmly press down on the part of the fuel pump gauge retainer closest to the front of the vehicle to keep it from rising up.

HINT:

- If the fuel pump gauge retainer cannot be properly pressed down due to the position of SST, set SST in a different position.

- When fully pressing down the fuel pump gauge retainer, there will be a sound or tactile sensation of parts contacting each other, and at this point the fuel suction tube with pump and gauge assembly will stop rising up.

(e) While pressing down on the fuel suction tube with pump and gauge assembly, have another person slowly tighten the fuel pump gauge retainer by approximately 180°.

|

*a |

SST (Plate) |

|

*b |

One Person in Charge of Tightening |

|

*c |

One Person in Charge of Pressing Down |

|

*d |

Approximately 180° |

|

*e |

Fuel Pump Gauge Retainer Start of Threads Location |

|

Press Down |

|

Slowly Rotate |

|

Front Side of Vehicle |

(f) Check the tightening status of the fuel pump gauge retainer.

(1) Using a vernier caliper, measure the distance from the fuel tank assembly to the upper surface of the fuel pump gauge retainer at 3 positions as shown in the illustration.

|

*1 |

Fuel Pump Gauge Retainer |

|

*2 |

Fuel Tank Assembly |

|

*a |

Measurement Position |

|

*b |

Vernier Caliper |

|

Front Side of Vehicle |

Standard:

Difference between the 3 measured values is 3 mm (0.118 in.) or less.

NOTICE:

If the difference between measurements is approximately 6 mm (0.236 in.), the threads are cross-threaded by 1 row (6 mm (0.236 in.)), so remove and reinstall the fuel pump gauge retainer.

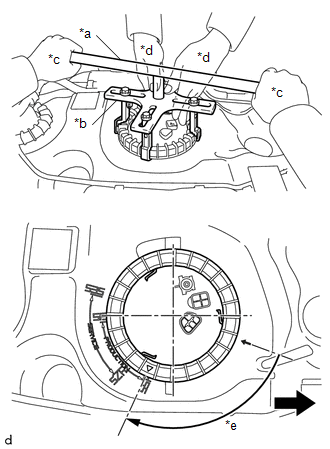

(g) Install SST (handle) to SST (plate).

SST: 09808-14031

09808-01010

09808-01020

|

*a |

SST (Handle) |

|

*b |

SST (Plate) |

|

*c |

One Person in Charge of Tightening |

|

*d |

One Person in Charge of Pressing Down |

|

*e |

Approximately 90° |

|

Front Side of Vehicle |

(h) While pressing down on the fuel suction tube with pump and gauge assembly, have another person use SST (handle) to slowly tighten the fuel pump gauge retainer approximately 90°.

|

*a |

SST (Handle) |

|

*b |

SST (Plate) |

|

*c |

Start of Threads of the Fuel Pump Gauge Retainer |

|

*d |

Fully Tightened Position |

|

Tighten |

|

Front Side of Vehicle |

(i) Slowly tighten the fuel pump gauge retainer until it reaches the fully tightened mark that was copied onto the vehicle body.

(j) If the start mark does not reach 475°, confirm that no cross threading occurred by measuring the gap between the fuel pump gauge retainer and the fuel tank.

If cross threading occurred, replace the fuel pump gauge retainer, the gasket and the tank suction tube support.

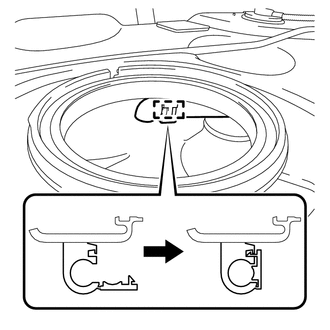

(k) Replace the tank suction tube support.

|

(1) Remove the tank suction tube support from the fuel tank. |

|

|

(2) Install the tank suction tube support to the fuel tank as shown in the illustration. |

|

(l) Put a mark on the fuel pump gauge retainer and the fuel tank with paint. This will be the evidence that the fuel pump gauge retainer has been removed.

|

*a |

Paint Mark |

|

Front Side of Vehicle |

10. INSTALL FUEL TANK VENT HOSE

(a) Engage the 4 clamps and install the fuel tank vent hose and hose clamp.

|

(b) Line up the pipe and connector and push them together until a "click" sound is heard. |

|

(c) Lock it by pushing in the retainer as shown in the illustration.

NOTICE:

- Check that there are no scratches or foreign objects on the connecting part.

- Check that the fuel tank vent hose is inserted securely.

- After installing the retainer, check that the fuel tank vent hose is securely connected by pulling on it.

HINT:

The quick connector cannot be locked when the tube is not inserted securely.

11. INSTALL CHARCOAL CANISTER OUTLET TUBE SUB-ASSEMBLY

(a) Engage the 4 clamps and install the charcoal canister outlet tube sub-assembly.

12. INSTALL FUEL TANK MAIN TUBE SUB-ASSEMBLY

(a) Engage the 4 guides and install the fuel tank main tube sub-assembly.

(b) Insert the fuel tank main tube into the fuel suction tube assembly plug and lock it with the tube joint clip.

|

*1 |

Tube Joint Clip |

|

*2 |

Fuel Tube Connector |

|

*3 |

O-ring |

|

*4 |

Collar |

|

*a |

Correct |

|

*b |

Incorrect |

|

Push Down |

|

Push |

NOTICE:

- Check that there are no scratches or foreign objects on the connecting part.

- Check that the fuel tank main tube is inserted securely.

- Check that the tube joint clip is on the collar of the main tube.

- After installing the tube joint clip, check that the fuel tank main tube assembly is securely connected by pulling on it.

13. INSTALL FUEL TANK ASSEMBLY

(a) Clean and degrease the bolt holes.

(b) Set the fuel tank and 3 fuel tank bands on the engine lifter.

(c) Slowly raise the engine lifter and install the fuel tank onto the vehicle.

NOTICE:

Make sure that the fuel tank does not fall.

(d) While operating the engine lifter, engage the 4 guides for the wire harness and connect the 2 fuel pump connectors, then install the fuel tank and the 3 fuel tank bands to the vehicle.

(e) Tighten the 6 set bolts of the 3 fuel tank bands.

Torque:

33 N·m {337 kgf·cm, 24 ft·lbf}

(f) Install the 2 wire harness clamps.

(g) Line up the pipe and connector and push them together until a "click" sound is heard.

NOTICE:

- Check if there is any damage or foreign objects on the connected part.

- After connecting, check if the connector and the pipe are securely connected by pulling on them.

(h) Connect the charcoal canister outlet tube.

NOTICE:

- Check that there are no scratches or foreign objects on the connecting part.

- Check that the charcoal canister outlet tube sub-assembly is inserted securely.

- Check that the charcoal canister outlet tube sub-assembly is securely connected by pulling on it.

14. CONNECT FUEL TANK INLET PIPE SUB-ASSEMBLY

|

(a) Connect the fuel tank inlet pipe sub-assembly to the fuel tank assembly and lock it by pushing in the retainer of quick connector. NOTICE:

|

|

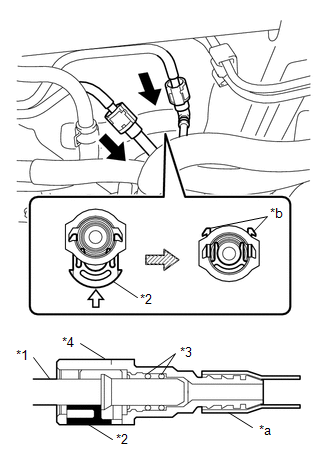

15. CONNECT FUEL TANK MAIN TUBE SUB-ASSEMBLY

NOTICE:

Check that there is no damage or foreign matter on the connecting parts of the fuel lines.

(a) Line up the pipe and connector and push them together until a "click" sound is heard.

|

*1 |

Fuel Pipe |

|

*2 |

Retainer |

|

*3 |

O-ring |

|

*4 |

Fuel Tube Connector |

|

*a |

Nylon Tube |

|

*b |

Claw |

|

Push |

|

Push in |

(b) Connect the fuel tank main tube sub-assembly to the fuel pipe.

(1) Align the fuel tube connector with the fuel pipe, and push them together until the fuel tube connector makes a "click" sound. If it is difficult to push the fuel pipe into the fuel tube connector, apply a small amount of clean gasoline to the tip of the fuel pipe and reinsert it.

(2) Connect the fuel lines and push in the retainer to engage the 2 claws. Check that the fuel pipe and fuel tube connector are securely connected by pulling on them.

16. CONNECT CHARCOAL CANISTER OUTLET TUBE SUB-ASSEMBLY

17. CONNECT FUEL TANK VENT HOSE

18. INSTALL NO. 1 FUEL TANK HEAT INSULATOR (for 2WD)

(a) Install the No. 1 fuel tank heat insulator with the 4 nuts.

Torque:

6.0 N·m {61 kgf·cm, 53 in·lbf}

19. INSTALL CENTER EXHAUST PIPE ASSEMBLY (for 2WD)

|

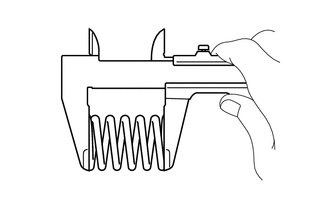

(a) Using a vernier caliper, measure the free length of the compression spring. Minimum Length: 38.86 mm (1.53 in.) If the length is not as specified, replace the compression spring. |

|

|

(b) Using a plastic hammer and a wooden block, tap in a new exhaust pipe gasket until its surface is flush with the front exhaust pipe assembly. NOTICE:

|

|

(c) Install a new gasket to the center exhaust pipe assembly.

(d) Hang the center exhaust pipe assembly with the 2 exhaust pipe supports.

(e) Install the 2 compression springs and 4 bolts.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

20. INSTALL PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY (for AWD)

21. ADD FUEL

22. INSPECT FOR FUEL LEAK

23. INSPECT FOR EXHAUST GAS LEAK

(a) Perform Inspection After Repair after repairing an exhaust gas leak.

24. INSTALL FUEL TANK FILLER HOSE COVER

(a) Install the 3 bolts and the fuel tank filler hose cover.

Torque:

5.0 N·m {51 kgf·cm, 44 in·lbf}

25. INSTALL REAR FLOOR NO. 2 CROSSMEMBER BRACE LH

(a) Install the rear floor No. 2 crossmember brace LH with 2 bolts.

Torque:

28 N·m {286 kgf·cm, 21 ft·lbf}

26. INSTALL CHARCOAL CANISTER PROTECTOR

|

|

|

![2017 - 2020 MY Sienna [08/2016 - ]; 2GR-FKS (FUEL): FUEL SYSTEM: PRECAUTION](/t3Portal/stylegraphics/info.gif)