| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000YW9Z |

| Model Year Start: 2017 | Model: Sienna | Prod Date Range: [08/2016 - ] |

| Title: 2GR-FKS (ENGINE MECHANICAL): ENGINE ASSEMBLY: INSTALLATION; 2017 - 2020 MY Sienna [08/2016 - ] | ||

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

Perform "Inspection After Repair" after replacing the engine assembly.

PROCEDURE

1. INSTALL REAR ENGINE MOUNTING INSULATOR ASSEMBLY (for AWD)

HINT:

Perform this procedure only when replacement of the rear engine mounting insulator assembly is necessary.

(a) Install the rear engine mounting insulator assembly to the front frame assembly with the 2 nuts.

Torque:

58 N·m {591 kgf·cm, 43 ft·lbf}

(b) Install the 2 hole plugs.

2. INSTALL ENGINE MOUNTING INSULATOR RH

HINT:

Perform this procedure only when replacement of the engine mounting insulator RH is necessary.

(a) Install the engine mounting insulator RH to the front frame assembly with the 3 nuts.

Torque:

99 N·m {1010 kgf·cm, 73 ft·lbf}

(b) Install the 2 hole plugs.

3. INSTALL ENGINE MOUNTING INSULATOR LH

HINT:

Perform this procedure only when replacement of the engine mounting insulator LH is necessary.

(a) Install the engine mounting insulator LH to the front frame assembly with the 3 nuts.

Torque:

99 N·m {1010 kgf·cm, 73 ft·lbf}

(b) Install the 2 hole plugs.

4. INSTALL FRONT ENGINE MOUNTING INSULATOR ASSEMBLY

HINT:

Perform this procedure only when replacement of the front engine mounting insulator assembly is necessary.

(a) Install the front engine mounting insulator assembly to the front frame assembly with the 3 nuts.

Torque:

58 N·m {591 kgf·cm, 43 ft·lbf}

(b) Install the hole plug.

5. INSTALL ENGINE HANGERS

6. REMOVE ENGINE ASSEMBLY FROM ENGINE STAND

(a) Remove the engine assembly from the engine stand.

7. INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

8. INSTALL ENGINE MOUNTING BRACKET RH

(a) Install the engine mounting bracket RH to the cylinder block sub-assembly with the 3 bolts.

Torque:

54 N·m {551 kgf·cm, 40 ft·lbf}

9. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY (for 2WD)

10. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY (for AWD)

11. INSTALL TRANSFER STIFFENER PLATE RH (for AWD)

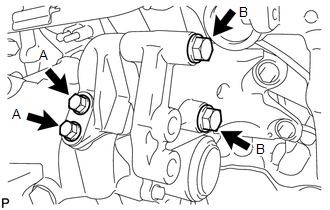

|

(a) Install the transfer stiffener plate RH to the rear engine mounting bracket and transfer assembly with the 4 bolts. Torque: Bolt A : 34 N·m {347 kgf·cm, 25 ft·lbf} Bolt B : 78 N·m {795 kgf·cm, 58 ft·lbf} |

|

12. INSTALL MANIFOLD STAY

(a) Install the manifold stay to the automatic transaxle assembly and exhaust manifold sab-assembly with the bolt and nut.

Torque:

Bolt :

34 N·m {347 kgf·cm, 25 ft·lbf}

Nut :

35 N·m {357 kgf·cm, 26 ft·lbf}

13. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH (for AWD)

14. INSTALL REAR ENGINE MOUNTING INSULATOR ASSEMBLY (for AWD)

(a) Install the rear engine mounting insulator assembly to the transfer assembly with the 2 bolts.

Torque:

75 N·m {765 kgf·cm, 55 ft·lbf}

15. INSTALL ENGINE MOUNTING INSULATOR RH

(a) Install the engine mounting insulator RH to the engine mounting bracket RH with the nut.

Torque:

95 N·m {969 kgf·cm, 70 ft·lbf}

16. INSTALL ENGINE MOUNTING INSULATOR LH

(a) Install the engine mounting insulator LH to the engine mounting bracket LH with the nut.

Torque:

95 N·m {969 kgf·cm, 70 ft·lbf}

17. INSTALL FRONT ENGINE MOUNTING INSULATOR ASSEMBLY

(a) Install the front engine mounting insulator assembly to the front engine mounting bracket with the bolt.

Torque:

87 N·m {887 kgf·cm, 64 ft·lbf}

18. INSTALL STEERING GEAR ASSEMBLY (for AWD)

19. INSTALL FRONT STABILIZER BAR (for AWD)

20. INSTALL NO. 1 FRONT STABILIZER BRACKET LH (for AWD)

21. INSTALL NO. 1 FRONT STABILIZER BRACKET RH (for AWD)

HINT:

Perform the same procedure as for the LH side.

22. INSTALL ENGINE WIRE

(a) Connect all the connectors and clamps, and install the engine wire to the engine assembly with transaxle.

23. INSTALL STARTER ASSEMBLY

24. INSTALL W/PULLEY COMPRESSOR ASSEMBLY

25. INSTALL GENERATOR ASSEMBLY

26. INSTALL FAN AND GENERATOR V BELT

27. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

(a) Set the engine assembly with transaxle on the engine lifter.

NOTICE:

- Install a height adjustment attachment and plate lift attachment onto the engine assembly with transaxle.

- Do not position a height adjustment attachment or plate lift attachment onto the front frame assembly.

(b) Remove the 4 bolts, No. 1 engine hanger and No. 2 engine hanger.

(c) Operate the engine lifter and install the engine assembly with transaxle to the vehicle.

CAUTION:

Do not raise the engine assembly with transaxle more than necessary. If the engine is raised excessively, the vehicle may also be lifted up.

NOTICE:

- Make sure that the engine assembly with transaxle is clear of all wiring and hoses.

- While raising the engine assembly with transaxle into the vehicle, do not allow it to contact the vehicle.

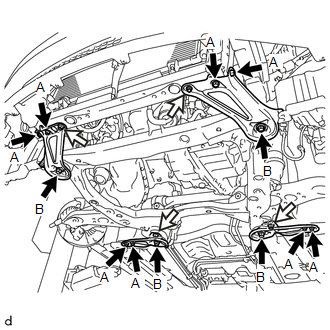

(d) Install the frame side rail plates RH and LH with the 6 bolts and 2 nuts.

|

Bolt |

|

Nut |

Torque:

Nut :

32.3 N·m {329 kgf·cm, 24 ft·lbf}

Bolt A :

32.3 N·m {329 kgf·cm, 24 ft·lbf}

Bolt B :

85 N·m {867 kgf·cm, 63 ft·lbf}

(e) Install the front suspension member rear braces RH and LH with the 6 bolts and 2 nuts.

Torque:

Nut :

32.3 N·m {329 kgf·cm, 24 ft·lbf}

Bolt A :

32.3 N·m {329 kgf·cm, 24 ft·lbf}

Bolt B :

85 N·m {867 kgf·cm, 63 ft·lbf}

(f) Engage the 2 clamps to connect the front fender liner LH and RH to the frame side rail plates LH and RH.

28. INSTALL DRIVE PLATE AND TORQUE CONVERTER SETTING BOLT

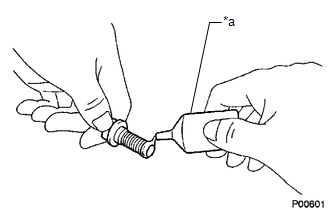

(a) Remove any adhesive remaining the 6 drive plate and torque converter assembly setting bolts.

|

(b) Apply a few drops of adhesive to 2 or 3 threads at the tip of each of the 6 drive plate and torque converter assembly setting bolts. Adhesive: Toyota Genuine Adhesive 1324, Three Bond 1324 or equivalent NOTICE: Make sure to install the 6 drive plate and torque converter assembly setting bolts immediately after applying adhesive to prevent foreign matter from attaching to them. |

|

(c) Turn the crankshaft to gain access to the installation locations of the 6 drive plate and torque converter assembly setting bolts and install each drive plate and torque converter assembly setting bolt while holding the crankshaft pulley bolt with a wrench.

Torque:

41 N·m {418 kgf·cm, 30 ft·lbf}

NOTICE:

First install the black colored drive plate and torque converter assembly setting bolt, and then the remaining 5 silver colored drive plate and torque converter assembly setting bolts.

29. INSTALL FLYWHEEL HOUSING UNDER COVER

(a) Install the flywheel housing under cover to the automatic transaxle case sub-assembly with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

30. INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

31. INSTALL FRONT DRIVE SHAFT ASSEMBLY RH (for 2WD)

32. INSTALL FRONT LOWER SUSPENSION ARM LH

33. INSTALL FRONT LOWER SUSPENSION ARM RH

HINT:

Perform the same procedure as for the LH side.

34. CONNECT TIE ROD ASSEMBLY LH

35. CONNECT TIE ROD ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

36. CONNECT FRONT SPEED SENSOR LH

37. CONNECT FRONT SPEED SENSOR RH

HINT:

Perform the same procedure as for the LH side.

38. CONNECT FRONT STABILIZER LINK ASSEMBLY LH

39. CONNECT FRONT STABILIZER LINK ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

40. INSTALL FRONT AXLE SHAFT NUT LH

41. INSTALL FRONT AXLE SHAFT NUT RH

HINT:

Perform the same procedure as for the LH side.

42. CONNECT STEERING INTERMEDIATE SHAFT ASSEMBLY

43. INSTALL NO. 1 EXHAUST PIPE SUPPORT BRACKET

(a) Install the No. 1 exhaust pipe support bracket to the oil pan sub-assembly with the 2 bolts.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

44. INSTALL FRONT EXHAUST PIPE ASSEMBLY (for 2WD)

45. INSTALL FRONT EXHAUST PIPE ASSEMBLY (for AWD)

46. INSTALL PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY (for AWD)

47. CONNECT SUCTION HOSE SUB-ASSEMBLY

48. CONNECT DISCHARGE HOSE SUB-ASSEMBLY

49. INSTALL ENGINE MOVING CONTROL ROD

HINT:

Perform this procedure only when replacement of the engine moving control rod is necessary.

(a) Temporarily install the engine moving control rod to the engine moving control rod bracket with the bolt.

50. INSTALL ENGINE MOVING CONTROL ROD BRACKET

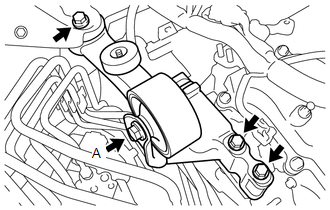

|

(a) When replacing the engine moving control rod: HINT: Perform this procedure only when replacement of the engine moving control rod is necessary. (1) Temporarily install the engine mounting control rod bracket together engine control rod to the front No. 1 engine mounting bracket RH and vehicle with the 3 bolts. (2) Tighten the bolts except A. Torque: 38 N·m {387 kgf·cm, 28 ft·lbf} (3) Tighten the bolt A. Torque: 52 N·m {530 kgf·cm, 38 ft·lbf} |

|

(b) When not replacing the engine moving control rod:

(1) Install the engine mounting control rod bracket together engine control rod to the front No. 1 engine mounting bracket RH and vehicle with the 3 bolts.

Torque:

38 N·m {387 kgf·cm, 28 ft·lbf}

51. INSTALL NO. 2 ENGINE MOUNTING STAY RH

(a) Install the No. 2 engine mounting stay RH to the front No. 1 engine mounting bracket RH with the bolt and 2 nuts.

Torque:

Bolt :

38 N·m {387 kgf·cm, 28 ft·lbf}

Nut :

23 N·m {235 kgf·cm, 17 ft·lbf}

52. INSTALL DUTY VACUUM SWITCHING VALVE

53. INSTALL TRANSMISSION OIL THERMOSTAT

54. CONNECT UNION TO CHECK VALVE HOSE

(a) Connect the union to check valve hose to the brake booster assembly and slide the clip to secure it.

55. CONNECT NO. 2 WATER HOSE SUB-ASSEMBLY

(a) Connect the No. 2 water hose sub-assembly to the water outlet and slide the clip to secure it.

56. CONNECT WATER HOSE SUB-ASSEMBLY

(a) Connect the water hose sub-assembly to the No. 2 water hose sub-assembly and slide the clip to secure it.

(b) Engage the clamp.

(c) Connect the water hose sub-assembly to the water outlet and slide the clip to secure it.

(d) Engage the clamp.

57. CONNECT NO. 1 RADIATOR HOSE

(a) Connect the No. 1 radiator hose to the water outlet and slide the clip to secure it.

58. CONNECT NO. 2 RADIATOR HOSE

(a) Connect the No. 2 radiator hose to the water inlet and slide the clip to secure it.

59. CONNECT NO. 1 FUEL HOSE

(a) Connect the fuel tube sub-assembly (for Port Injection).

(1) Connect the fuel tube sub-assembly to the fuel pipe.

(b) Connect the No. 2 fuel tube sub-assembly (for Direct Injection).

(1) Connect the No. 2 fuel tube sub-assembly to the fuel pipe.

(c) Install the No. 1 fuel pipe clamp to the fuel tube connector.

(d) Install the No. 2 fuel pipe clamp to the No. 1 fuel pipe clamp.

60. CONNECT FUEL VAPOR FEED HOSE ASSEMBLY

(a) Connect the fuel vapor feed hose assembly to the purge VSV (purge valve) and slide the clip to secure it.

(b) Connect the purge VSV (purge valve) connector.

61. CONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

62. CONNECT ENGINE WIRE

(a) Engage the 2 clamps and connect the engine wire to the vehicle.

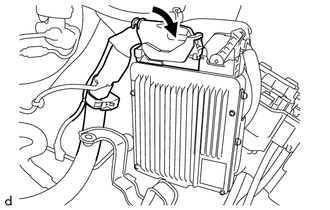

|

(b) Connect the ECM connector and lock with the lever. NOTICE:

|

|

(c) Engage the 2 claws to connect the engine wire to the engine room relay block.

(d) Engage the 2 clamps to connect the engine wire to the air cleaner support bracket and vehicle.

(e) Connect the engine wire to the vehicle with the bolt.

Torque:

8.4 N·m {86 kgf·cm, 74 in·lbf}

(f) Install the nut to the engine room relay block.

Torque:

8.4 N·m {86 kgf·cm, 74 in·lbf}

(g) Connect the 3 connectors.

(h) Install the engine room relay block cover to the engine room relay block.

63. INSTALL AIR CLEANER BRACKET

(a) Install the air cleaner bracket to the vehicle with the 2 bolts.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

(b) Engage the clamp.

64. INSTALL AIR CLEANER CASE SUB-ASSEMBLY

(a) Install the air cleaner case sub-assembly to the air cleaner bracket with the 2 bolts.

Torque:

5.0 N·m {51 kgf·cm, 44 in·lbf}

65. INSTALL AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

(a) Install the air cleaner filter element sub-assembly to the air cleaner case sub-assembly.

66. INSTALL AIR CLEANER CAP WITH AIR CLEANER HOSE

67. INSTALL AIR CLEANER INLET ASSEMBLY

(a) Install the air cleaner inlet assembly to the vehicle with the 2 bolts.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

(b) Engage the clamp.

68. INSTALL BATTERY

(a) Install the battery tray to the vehicle.

(b) Install the battery to the battery tray.

(c) Install the battery clamp with the bolt and nut.

Torque:

5.5 N·m {56 kgf·cm, 49 in·lbf}

(d) Connect the cable to the positive (+) battery terminal and tighten the nut.

Torque:

5.4 N·m {55 kgf·cm, 48 in·lbf}

69. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

70. INSTALL WINDSHIELD WIPER MOTOR AND LINK

71. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

72. INSTALL FRONT WHEEL

Torque:

103 N·m {1050 kgf·cm, 76 ft·lbf}

73. ADD ENGINE OIL

74. ADD ENGINE COOLANT

75. ADD TRANSFER OIL (for AWD)

76. INSPECT TRANSFER OIL (for AWD)

77. ADD AUTOMATIC TRANSAXLE FLUID (for 2WD)

78. ADD AUTOMATIC TRANSAXLE FLUID (for AWD)

79. WARM UP ENGINE

80. INSPECT ENGINE OIL LEVEL

81. INSPECT ENGINE COOLANT LEVEL IN RESERVOIR TANK

82. CHARGE REFRIGERANT

83. INSPECT FOR CHECK FUEL PUMP OPERATION AND INSPECT FOR FUEL LEAK

84. INSPECT FOR COOLANT LEAK

85. INSPECT FOR OIL LEAK

86. INSPECT FOR EXHAUST GAS LEAK

87. INSPECT IGNITION TIMING

88. INSPECT ENGINE IDLE SPEED

89. INSPECT CO/HC

90. CHECK FOR SPEED SENSOR SIGNAL

91. INSPECT SHIFT LEVER POSITION (for 2WD)

92. INSPECT SHIFT LEVER POSITION (for AWD)

93. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

94. INSTALL V-BANK COVER SUB-ASSEMBLY

(a) Engage the 4 clips in the order shown in the illustration to install the V-bank cover sub-assembly.

95. INSTALL FRONT FENDER APRON SEAL LH

(a) Install the front fender apron seal LH with the bolt and 2 clips.

96. INSTALL FRONT FENDER APRON SEAL RH

(a) Install the front fender apron seal RH with the 2 bolts and clip.

97. INSTALL NO. 2 ENGINE UNDER COVER (for AWD)

98. INSTALL NO. 1 ENGINE UNDER COVER

99. INSTALL INSTRUMENT PANEL FINISH PANEL END LH

|

|

|

![2017 MY Sienna [08/2016 - 11/2017]; 2GR-FKS (ENGINE CONTROL): SFI SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)