- ON: Shift lever in S, "+" or "-"

- OFF: Shift lever not in S, "+" or "-"

| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000YIZL |

| Model Year Start: 2017 | Model: Sienna | Prod Date Range: [08/2016 - ] |

| Title: UA80E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: Transmission Control Switch Circuit; 2017 - 2020 MY Sienna [08/2016 - ] | ||

|

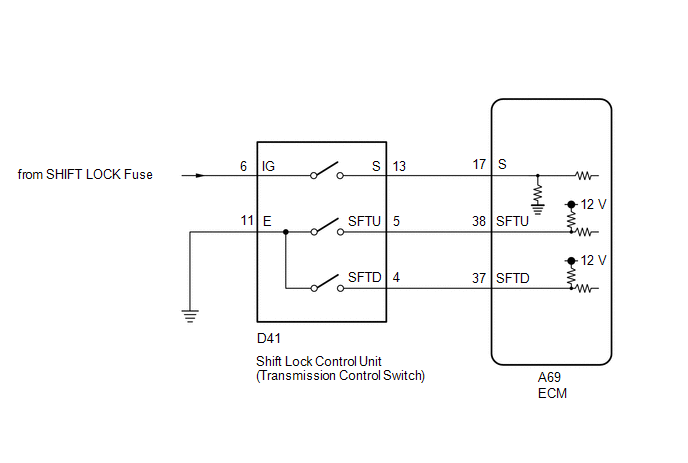

Transmission Control Switch Circuit |

DESCRIPTION

When the shift lever is in S and moved toward "-" or "+", it is possible to select different shift ranges (S1 to S8).

Moving the shift lever toward "+" increases the shift range by one, and moving the shift lever toward "-" decreases the shift range by one.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (SHIFT SW STATUS (S RANGE)) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Transmission / Data List

(e) Read the Data List according to the display on the Techstream.

Transmission

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Shift SW Status (S Range) |

Sport (S) mode select switch status |

ON or OFF |

|

- |

|

Result |

Proceed to |

|---|---|

|

Data List values are normal |

A |

|

Data List values are not normal |

B |

| B |

|

|

|

2. |

READ VALUE USING TECHSTREAM (SPORT SHIFT UP SW AND SPORT SHIFT DOWN SW) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Data List

(e) Read the Data List according to the display on the Techstream.

Engine

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Sport Shift Up SW |

Sport shift up switch status |

ON or OFF |

|

- |

|

Sport Shift Down SW |

Sport shift down switch status |

ON or OFF |

|

- |

|

Result |

Proceed to |

|---|---|

|

Data List values are normal |

A |

|

Data List values are not normal |

B |

| A |

|

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

3. |

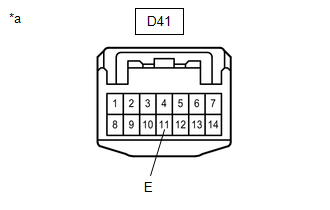

INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY (TRANSMISSION CONTROL SWITCH) |

(a) Disconnect the D41 transmission control switch connector.

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |

|

REPLACE SHIFT LOCK CONTROL UNIT ASSEMBLY (TRANSMISSION CONTROL SWITCH) |

|

|

4. |

CHECK HARNESS AND CONNECTOR (TRANSMISSION CONTROL SWITCH - BODY GROUND) |

|

(a) Disconnect the transmission control switch connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D41-11 (E) - Body ground |

Always |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

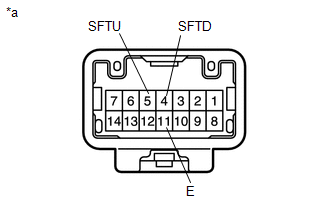

CHECK HARNESS AND CONNECTOR (TRANSMISSION CONTROL SWITCH - ECM) |

(a) Connect the D41 transmission control switch connector.

(b) Disconnect the A69 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A69-38 (SFTU) - Body ground |

Shift lever held in "+" (Up shift) |

Below 1 Ω |

|

Shift lever not held in "+" (Up shift) |

10 kΩ or higher |

|

|

A69-37 (SFTD) - Body ground |

Shift lever held in "-" (Down shift) |

Below 1 Ω |

|

Shift lever not held in "-" (Down shift) |

10 kΩ or higher |

| OK |

|

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (TRANSMISSION CONTROL SWITCH - ECM) |

|

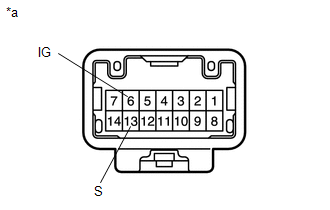

6. |

INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY (TRANSMISSION CONTROL SWITCH) |

|

(a) Disconnect the D41 transmission control switch connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

6 (IG) - 13 (S) |

Shift lever in S, "+" or "-" |

Below 1 Ω |

|

Shift lever not in S, "+" or "-" |

10 kΩ or higher |

| NG |

|

REPLACE SHIFT LOCK CONTROL UNIT ASSEMBLY (TRANSMISSION CONTROL SWITCH) |

|

|

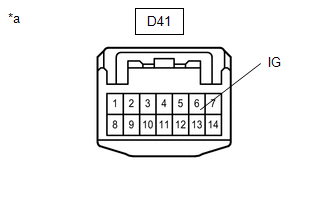

7. |

CHECK HARNESS AND CONNECTOR (TRANSMISSION CONTROL SWITCH (POWER SOURCE)) |

|

(a) Disconnect the transmission control switch connector. |

|

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

D41-6 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

8. |

CHECK HARNESS AND CONNECTOR (TRANSMISSION CONTROL SWITCH - ECM) |

(a) Disconnect the D41 transmission control switch connector.

(b) Disconnect the A69 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

D41-13 (S) - A69-17 (S) |

Always |

Below 1 Ω |

|

D41-13 (S) or A69-17 (S) - Body ground and other terminals |

Always |

10 kΩ or higher |

| OK |

|

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|