| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000VKA3 |

| Model Year Start: 2016 | Model: Sienna | Prod Date Range: [12/2015 - ] |

| Title: DOOR / HATCH: BACK DOOR CLOSER SYSTEM: Back Door Closer does not Operate; 2016 - 2020 MY Sienna [12/2015 - ] | ||

|

Back Door Closer does not Operate |

DESCRIPTION

When the back door closer does not operate, one of the following may be the cause: 1) improper fit of the back door, or a foreign object is stuck in the back door, 2) initialization of the power back door ECU (power back door motor unit), 3) a malfunction in the power back door ECU (power back door motor unit) power source circuit, 4) back door lock circuit, 5) power back door ECU (power back door motor unit) or 6) touch sensor circuit.

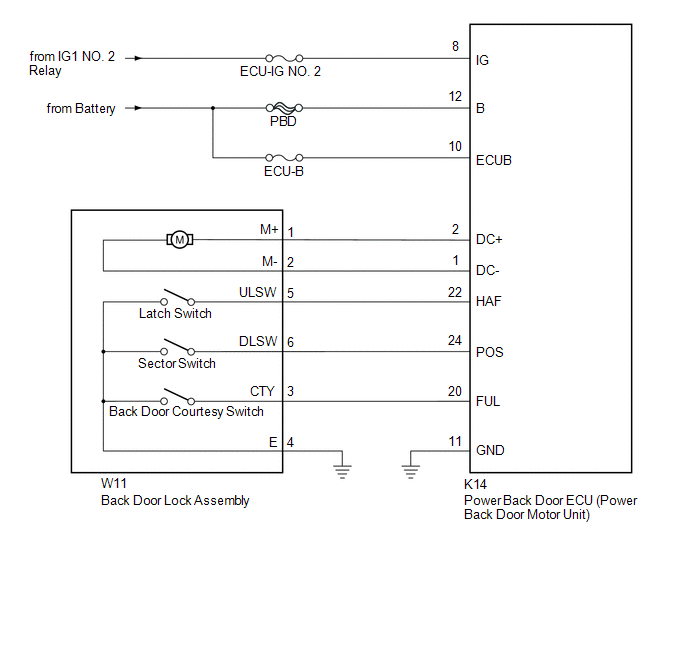

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK BACK DOOR LOCK FUNCTION |

(a) Check if the back door is fully closed by hand.

OK:

The back door is fully closed.

| NG |

|

IMPROPER FIT OF BACK DOOR, OR A FOREIGN OBJECT IS STUCK IN BACK DOOR |

|

|

2. |

INITIALIZE POWER BACK DOOR ECU |

(a) Perform the initialization of the power back door ECU (power back door motor unit) (See page

![2016 - 2020 MY Sienna [12/2015 - ]; DOOR / HATCH: BACK DOOR CLOSER SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif) ).

).

|

|

3. |

CHECK BACK DOOR CLOSER SYSTEM |

(a) Check back door closer system operation.

OK:

Back door closer system operates normally.

| OK |

|

END |

|

|

4. |

READ VALUE USING TECHSTREAM (POWER BACK DOOR TOUCH SENSOR) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Back Door / Data List.

(e) Check the Data List to determine if the power back door touch sensor functions properly.

Back Door (Power Back Door ECU)

|

Tester Display |

Measurement Item/Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|

|

PBD Touch Sensor (Right) |

Power back door touch sensor RH signal / ON or OFF |

ON: Power back door touch sensor RH pressed OFF: Power back door touch sensor RH not pressed |

- |

|

PBD Touch Sensor (Left) |

Power back door touch sensor LH signal / ON or OFF |

ON: Power back door touch sensor LH pressed OFF: Power back door touch sensor LH not pressed |

- |

OK:

The power back door sensors function as specified in the normal condition column.

| NG |

|

|

|

5. |

CHECK DTC OUTPUT |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Back Door / DTC.

(e) Check for DTCs.

Result

|

Result |

Proceed to |

|---|---|

|

DTC is not output |

A |

|

B2250 is output |

B |

|

B2251 is output |

C |

| B |

|

| C |

|

|

|

6. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE) |

|

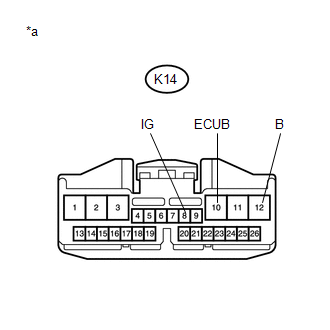

(a) Disconnect the K14 power back door ECU connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

K14-8 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

|

K14-10 (ECUB) - Body ground |

Always |

11 to 14 V |

|

K14-12 (B) - Body ground |

Always |

11 to 14 V |

Text in Illustration

|

*a |

Front view of wire harness connector (to Power Back Door ECU) |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

7. |

CHECK HARNESS AND CONNECTOR (BODY GROUND) |

|

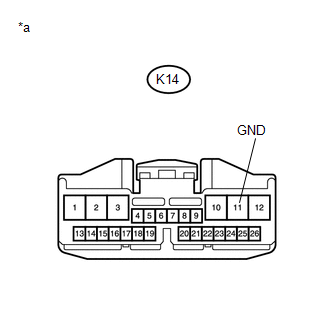

(a) Disconnect the K14 power back door ECU connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

K14-11 (GND) - Body ground |

Always |

Below 1 Ω |

Text in Illustration

|

*a |

Front view of wire harness connector (to Power Back Door ECU) |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

8. |

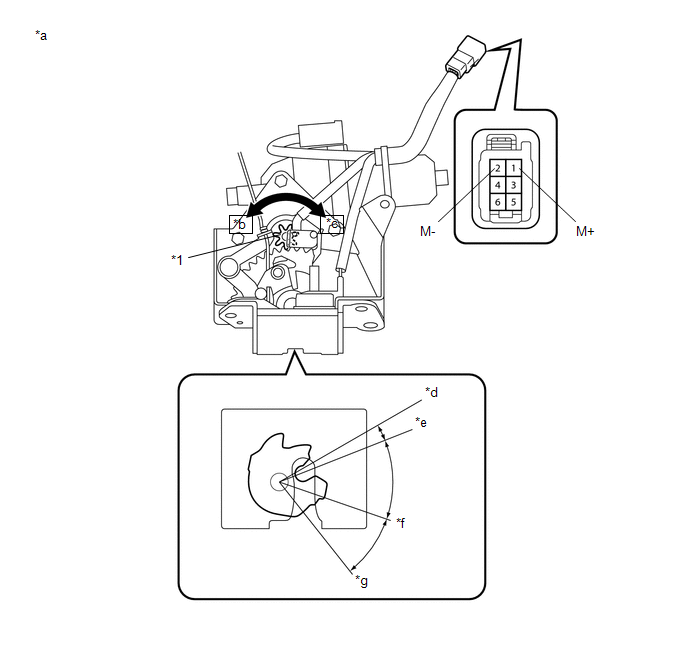

INSPECT BACK DOOR LOCK ASSEMBLY |

(a) Remove the back door lock assembly (See page

![2016 - 2020 MY Sienna [12/2015 - ]; DOOR LOCK: BACK DOOR LOCK: REMOVAL](/t3Portal/stylegraphics/info.gif) ).

).

(b) Check the operation of the back door closer motor.

(1) Apply battery voltage and check the operation of the door lock motor.

Text in Illustration

|

*1 |

Drive Gear |

- |

- |

|

*a |

Component without harness connected (Back Door Lock Assembly) |

*b |

Release |

|

*c |

Close |

*d |

Over-latch |

|

*e |

Full-latch |

*f |

Half-latch |

|

*g |

Open-latch |

- |

- |

OK:

|

Measurement Condition |

Specified Condition |

|---|---|

|

Battery positive (+) → Terminal 1 (M+) Battery negative (-) → Terminal 2 (M-) |

Latch turns to full-latch position |

|

Battery positive (+) → Terminal 2 (M-) Battery negative (-) → Terminal 1 (M+) |

Latch turns to open-latch position |

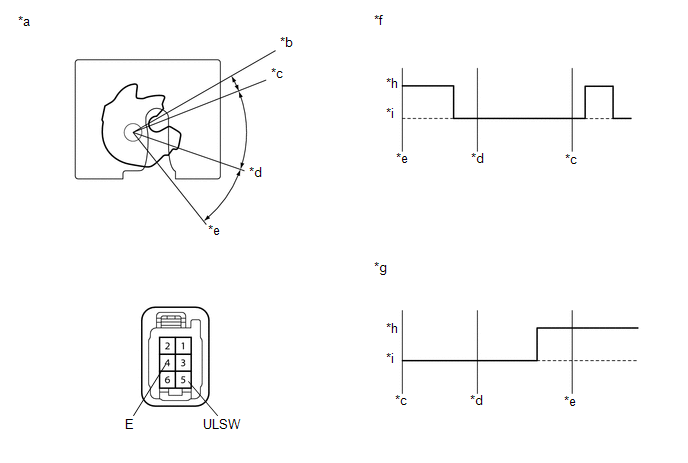

(c) Check the operation of the latch switch.

Text in Illustration

|

*a |

Component without harness connected (Back Door Lock Assembly) |

*b |

Over-latch |

|

*c |

Full-latch |

*d |

Half-latch |

|

*e |

Open-latch |

*f |

Latch Switch (Close Operation) |

|

*g |

Latch Switch (Open Operation) |

*h |

ON |

|

*i |

OFF |

- |

- |

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

Close Operation

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

5 (ULSW) - 4 (E) |

Open-latch |

Below 1 Ω |

|

Open-latch → Half-latch |

Below 1 Ω → 10 kΩ or higher |

|

|

Half-latch |

10 kΩ or higher |

|

|

Full-latch |

10 kΩ or higher |

|

|

Over-latch |

10 kΩ or higher → Below 1 Ω → 10 kΩ or higher |

Open Operation

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

5 (ULSW) - 4 (E) |

Full-latch |

10 kΩ or higher |

|

Half-latch |

10 kΩ or higher |

|

|

Half-latch → Open-latch |

10 kΩ or higher → Below 1 Ω |

|

|

Open-latch |

Below 1 Ω |

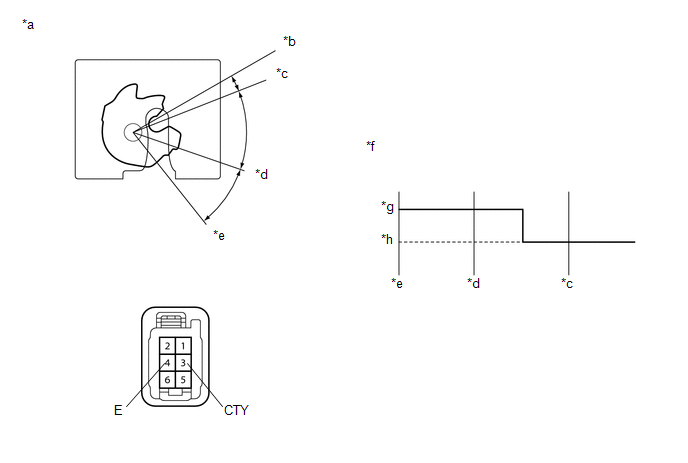

(d) Check the operation of the back door courtesy switch.

Text in Illustration

|

*a |

Component without harness connected (Back Door Lock Assembly) |

*b |

Over-latch |

|

*c |

Full-latch |

*d |

Half-latch |

|

*e |

Open-latch |

*f |

Back Door Courtesy Switch |

|

*g |

ON |

*h |

OFF |

(1) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3 (CTY) - 4 (E) |

Open-latch |

Below 1 Ω |

|

Half-latch |

Below 1 Ω |

|

|

Full-latch |

10 kΩ or higher |

|

|

Over-latch |

10 kΩ or higher |

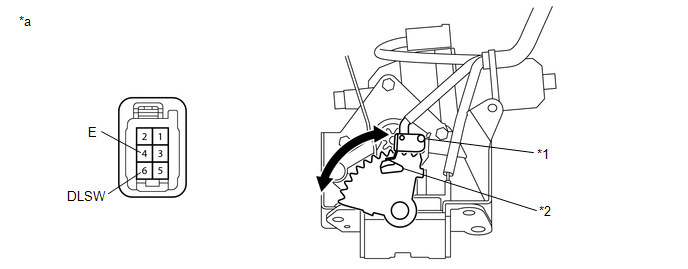

(e) Check the operation of the sector switch.

Text in Illustration

|

*1 |

Sector Switch |

*2 |

Sector Gear |

|

*a |

Component without harness connected (Back Door Lock Assembly) |

- |

- |

(1) Measure the resistance according to the value(s) in the below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

6 (DLSW) - 4 (E) |

Sector gear in neutral position (sector switch on) |

Below 1 Ω |

|

Sector gear not in neutral position (sector switch off) |

10 kΩ or higher |

| NG |

|

|

|

9. |

CHECK HARNESS AND CONNECTOR (BACK DOOR LOCK ASSEMBLY - POWER BACK DOOR ECU) |

(a) Disconnect the W11 back door lock assembly connector and K14 power back door ECU connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

W11-1 (M+) - K14-2 (DC+) |

Always |

Below 1 Ω |

|

W11-2 (M-) - K14-1 (DC-) |

Always |

Below 1 Ω |

|

W11-5 (ULSW) - K14-22 (HAF) |

Always |

Below 1 Ω |

|

W11-6 (DLSW) - K14-24 (POS) |

Always |

Below 1 Ω |

|

W11-3 (CTY) - K14-20 (FUL) |

Always |

Below 1 Ω |

|

W11-4 (E) - Body ground |

Always |

Below 1 Ω |

|

W11-1 (M+) - Body ground |

Always |

10 kΩ or higher |

|

W11-2 (M-) - Body ground |

Always |

10 kΩ or higher |

|

W11-5 (ULSW) - Body ground |

Always |

10 kΩ or higher |

|

W11-6 (DLSW) - Body ground |

Always |

10 kΩ or higher |

|

W11-3 (CTY) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|