- Receiver dryer oversaturated

- Moisture in refrigeration system freezes at expansion valve orifice and blocks refrigerant circulation

| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000VK1U |

| Model Year Start: 2016 | Model: Sienna | Prod Date Range: [12/2015 - ] |

| Title: HEATING / AIR CONDITIONING: REFRIGERANT: ON-VEHICLE INSPECTION; 2016 - 2020 MY Sienna [12/2015 - ] | ||

ON-VEHICLE INSPECTION

PROCEDURE

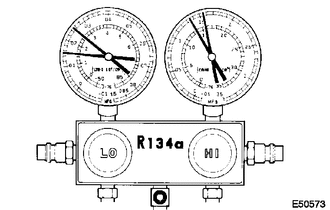

1. CHECK REFRIGERANT PRESSURE USING MANIFOLD GAUGE SET

(a) This is a method to identify trouble areas by using a manifold gauge set. Read the manifold gauge pressure under the following conditions.

Test conditions:

- Engine warm.

- All doors fully open.

- A/C switch is on.

- Blower speed control switch at HI.

- Engine running at 1500 rpm.

- Air inlet mode damper set at RECIRC.

- Temperature control switch in MAX. COLD position.

- Air temperature at air inlet 30 to 35°C (86 to 95°F).

|

(1) When the refrigerant volume is correct, the gauge reading indicates as follows: Gauge Reading:

HINT: Pressure varies in accordance with certain conditions (outside air temperature, sunlight and wind). |

|

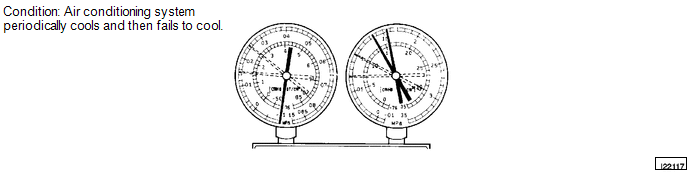

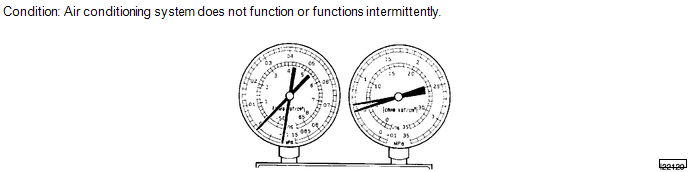

(2) When there is moisture in the refrigeration system:

|

Symptom |

Probable Cause |

Diagnosis |

Corrective Action |

|---|---|---|---|

|

During operation, pressure on low pressure side cycles between normal and vacuum |

Moisture in refrigeration system freezes at expansion valve orifice, causing temporary interruption of cycle However, when melted, returns to normal condition |

|

|

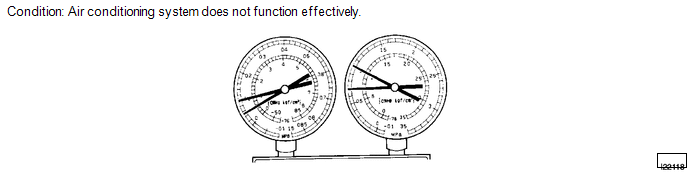

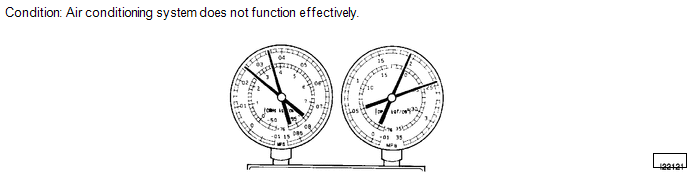

(3) When cooling is insufficient:

|

Symptom |

Probable Cause |

Diagnosis |

Corrective Action |

|---|---|---|---|

|

Gas leakage from refrigeration system |

|

|

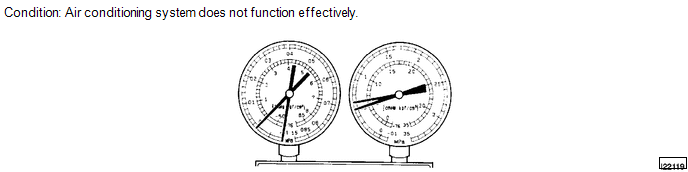

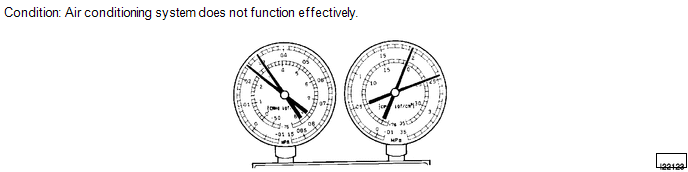

(4) When the circulation of the refrigerant is poor:

|

Symptom |

Probable Cause |

Diagnosis |

Corrective Action |

|---|---|---|---|

|

Refrigerant flow obstructed by dirt in condenser |

Condenser clogged |

Replace condenser |

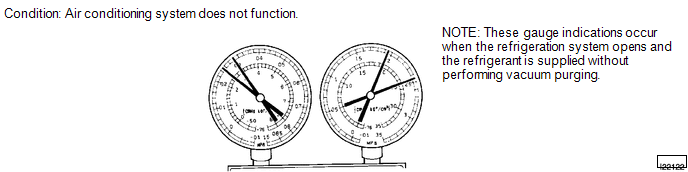

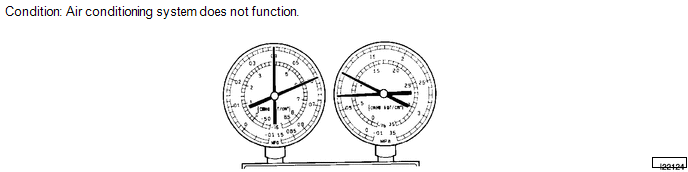

(5) When the refrigerant does not circulate:

|

Symptom |

Probable Cause |

Diagnosis |

Corrective Action |

|---|---|---|---|

|

|

Refrigerant does not circulate |

|

(6) When the refrigerant is overcharged or cooling of condenser is insufficient:

|

Symptom |

Probable Cause |

Diagnosis |

Corrective Action |

|---|---|---|---|

|

|

|

|

(7) When there is air in the refrigeration system:

|

Symptom |

Probable Cause |

Diagnosis |

Corrective Action |

|---|---|---|---|

|

Air in refrigeration system |

|

|

(8) When the expansion valve malfunctions:

|

Symptom |

Probable Cause |

Diagnosis |

Corrective Action |

|---|---|---|---|

|

Expansion valve malfunction |

|

Replace expansion valve |

(9) When the compressor is defective:

|

Symptom |

Probable Cause |

Diagnosis |

Corrective Action |

|---|---|---|---|

|

Internal leakage in compressor |

|

Repair or replace compressor |

2. INSPECT IDLING SPEED

(a) Warm up the engine.

(b) Inspect idling speed when these conditions are established.

- Check the idle speed with the cooling fans off.

- Turn off all the electrical systems.

- When checking the idle speed, the transaxle should be in neutral or park.

Standard:

|

Condition |

Idling Speed |

|---|---|

|

A/C switch is off |

600 to 700 rpm |

|

A/C switch is on (A/C Lo → Hi) |

650 → 800 rpm |

If the idling speed is not as specified, check the idle control system.

|

|

|