- Occupant classification ECU circuit malfunction

- Occupant classification ECU malfunction

- Occupant classification ECU receives short circuit to ground signal in passenger side buckle switch circuit for 2 seconds

| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000VJSB |

| Model Year Start: 2016 | Model: Sienna | Prod Date Range: [12/2015 - ] |

| Title: SUPPLEMENTAL RESTRAINT SYSTEMS: OCCUPANT CLASSIFICATION SYSTEM: B1794; Open in Occupant Classification ECU Battery Positive Line; 2016 - 2020 MY Sienna [12/2015 - ] | ||

|

DTC |

B1794 |

Open in Occupant Classification ECU Battery Positive Line |

DESCRIPTION

DTC B1794 is stored when a malfunction is detected in the occupant classification ECU.

|

DTC Code |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

B1794 |

One of following conditions is met: |

|

HINT:

- When DTC B1650/32 is detected as a result of troubleshooting the airbag system, perform troubleshooting for DTC B1794 of the occupant classification system.

- Use the Techstream to check for DTCs of the occupant classification ECU, otherwise the DTCs cannot be read.

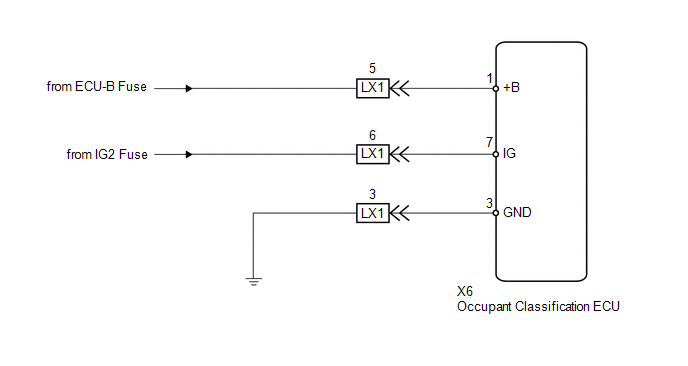

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK FOR DTC |

(a) Turn the ignition switch to ON, and wait for at least 60 seconds.

(b) Clear any DTCs stored in the memory (See page

![2016 - 2020 MY Sienna [12/2015 - ]; SUPPLEMENTAL RESTRAINT SYSTEMS: OCCUPANT CLASSIFICATION SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif) ).

).

HINT:

- First clear DTCs stored in the occupant classification ECU and then in the center airbag sensor assembly.

- Use the Techstream to clear the DTCs of the occupant classification ECU, otherwise the DTCs cannot be cleared.

(c) Turn the ignition switch off.

(d) Turn the ignition switch to ON, and wait for at least 60 seconds.

(e) Using the Techstream, check for DTCs of the occupant classification ECU (See page

![2016 - 2020 MY Sienna [12/2015 - ]; SUPPLEMENTAL RESTRAINT SYSTEMS: OCCUPANT CLASSIFICATION SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif) ).

).

OK:

DTC B1794 is not output.

HINT:

DTCs other than DTC B1794 may be output at this time, but they are not related to this check.

| OK |

|

|

|

2. |

CHECK CONNECTION OF CONNECTOR |

(a) Turn the ignition switch off.

(b) Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

(c) Check that the connector are properly connected to the occupant classification ECU. Also check that the connectors that link the front seat wire RH and No. 2 floor wire are properly connected.

OK:

Connectors are properly connected.

| NG |

|

CONNECT CONNECTORS PROPERLY |

|

|

3. |

CHECK CONNECTOR |

(a) Check that the connectors (on the occupant classification ECU side, front seat wire RH side and No. 2 floor wire side) are not damaged.

OK:

Connectors are not deformed or damaged.

| NG |

|

REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK HARNESS AND CONNECTOR (SOURCE VOLTAGE) |

|

(a) Turn the ignition switch off. |

|

(b) Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

(c) Disconnect the front seat wire RH connector from the No. 2 floor wire.

(d) Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

(e) Turn the ignition switch to ON, and wait for at least 60 seconds.

(f) Measure the resistance and voltage according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

LX1-3 (GND) - Body ground |

Always |

Below 1 Ω |

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

LX1-5 (+B) - Body ground |

Ignition switch ON |

11 to 14 V |

|

LX1-6 (IG) - Body ground |

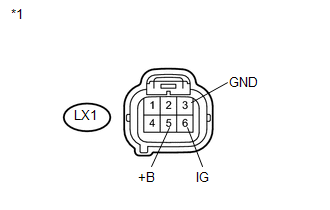

Text in Illustration

|

*1 |

Front view of wire harness connector (to Front Seat Wire RH) |

| NG |

|

REPLACE HARNESS OR CONNECTOR |

|

|

5. |

CHECK FRONT SEAT WIRE RH (SOURCE VOLTAGE) |

|

(a) Turn the ignition switch off. |

|

(b) Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

(c) Connect the front seat wire RH connector from the No. 2 floor wire.

(d) Disconnect the X6 occupant classification ECU connector.

(e) Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

(f) Turn the ignition switch to ON, and wait for at least 60 seconds.

(g) Measure the resistance and voltage according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

X6-3 (GND) - Body ground |

Always |

Below 1 Ω |

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

X6-1 (+B) - Body ground |

Ignition switch ON |

11 to 14 V |

|

X6-7 (IG) - Body ground |

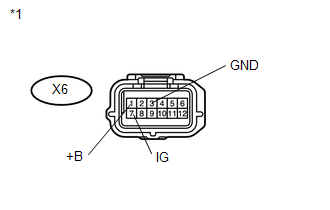

Text in Illustration

|

*1 |

Front view of wire harness connector (to Occupant Classification ECU) |

| NG |

|

REPLACE FRONT SEAT WIRE RH |

|

|

6. |

CHECK FOR DTC |

(a) Turn the ignition switch off.

(b) Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

(c) Connect the connectors to the occupant classification ECU.

(d) Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

(e) Turn the ignition switch to ON, and wait for at least 60 seconds.

(f) Clear any DTCs stored in the memory (See page

![2016 - 2020 MY Sienna [12/2015 - ]; SUPPLEMENTAL RESTRAINT SYSTEMS: OCCUPANT CLASSIFICATION SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif) ).

).

HINT:

- First clear DTCs stored in the occupant classification ECU and then in the center airbag sensor assembly.

- Use the Techstream to clear the DTCs of the occupant classification ECU, otherwise the DTCs cannot be cleared.

(g) Turn the ignition switch off.

(h) Turn the ignition switch to ON, and wait for at least 60 seconds.

(i) Using the Techstream, check for DTCs of the occupant classification ECU (See page

![2016 - 2020 MY Sienna [12/2015 - ]; SUPPLEMENTAL RESTRAINT SYSTEMS: OCCUPANT CLASSIFICATION SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif) ).

).

OK:

DTC B1794 is not output.

HINT:

DTCs other than DTC B1794 may be output at this time, but they are not related to this check.

| OK |

|

|

|

7. |

REPLACE OCCUPANT CLASSIFICATION ECU |

(a) Turn the ignition switch off.

(b) Disconnect the cable from the negative (-) battery terminal, and wait for at least 90 seconds.

(c) Replace the occupant classification ECU (See page

![2016 - 2020 MY Sienna [12/2015 - ]; SUPPLEMENTAL RESTRAINT SYSTEMS: OCCUPANT CLASSIFICATION ECU: REMOVAL](/t3Portal/stylegraphics/info.gif) ).

).

HINT:

Perform the inspection using parts from a normal vehicle when possible.

|

|

8. |

PERFORM ZERO POINT CALIBRATION |

(a) Connect the cable to the negative (-) battery terminal, and wait for at least 2 seconds.

(b) Connect the Techstream to the DLC3.

(c) Turn the ignition switch to ON, and wait for at least 60 seconds.

(d) Using the Techstream, perform the zero point calibration (See page

![2016 - 2020 MY Sienna [12/2015 - ]; SUPPLEMENTAL RESTRAINT SYSTEMS: OCCUPANT CLASSIFICATION SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif) ).

).

|

|

9. |

PERFORM SENSITIVITY CHECK |

(a) Using the Techstream, perform the sensitivity check (See page

![2016 - 2020 MY Sienna [12/2015 - ]; SUPPLEMENTAL RESTRAINT SYSTEMS: OCCUPANT CLASSIFICATION SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif) ).

).

Standard range:

27 to 33 kg (59.5 to 72.8 lb)

| NEXT |

|

END |

|

|

|