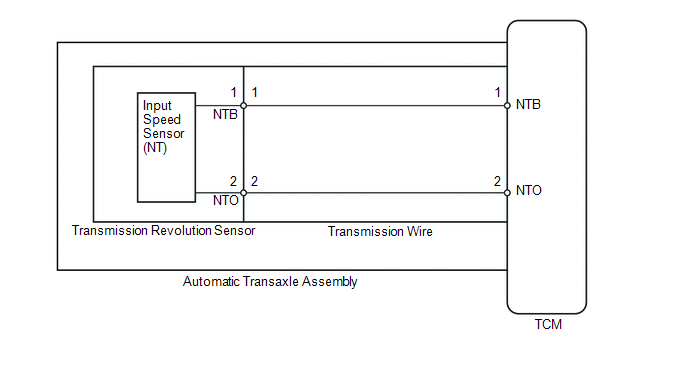

- Transmission revolution sensor (Input speed sensor NT)

- Transmission wire

- TCM

| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000VIKK |

| Model Year Start: 2016 | Model: Sienna | Prod Date Range: [12/2015 - 08/2016] |

| Title: U660E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: P0715,P0717; Input / Turbine Speed Sensor Circuit Malfunction; 2016 MY Sienna [12/2015 - 08/2016] | ||

|

DTC |

P0715 |

Input / Turbine Speed Sensor Circuit Malfunction |

|

DTC |

P0717 |

Input Speed Sensor Circuit No Signal |

DESCRIPTION

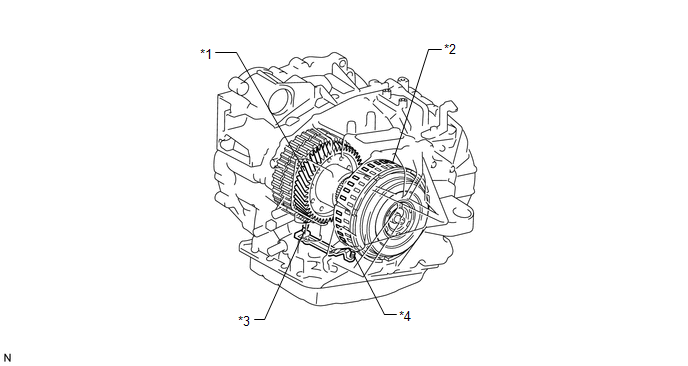

This sensor detects the rotation speed of the turbine which shows the input speed of the transaxle. By comparing the input speed signal (NT) with the output speed sensor signal (NC), the TCM detects the shift timing of the gears and appropriately controls the engine torque and hydraulic pressure according to various conditions, thus, providing smooth gear shifts.

Text in Illustration

|

*1 |

Counter Gear |

*2 |

Clutch Drum |

|

*3 |

Output Speed Sensor (NC) |

*4 |

Input Speed Sensor (NT) |

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

P0715 |

When the speed sensor input voltage is either more than 1.9 V or less than 0.1 V for 4.5 seconds or more (1 trip detection logic). |

|

|

P0717 |

All conditions below are detected for 5 seconds or more (1 trip detection logic). (a) Gear change is not being performed. (b) Gear position: 2nd, 3rd, 4th, 5th or 6th. (c) T/M output shaft speed: 1000 rpm or more. (d) Park/neutral position switch (NSW and R) is OFF (e) Park/neutral position switch and vehicle speed sensor are in normal operation. (f) T/M input shaft speed: Less than 300 rpm. |

MONITOR DESCRIPTION

The NT terminal of the TCM detects a revolution signal from the input speed sensor (NT). The TCM calculates gear shifts comparing the input speed sensor (NT) with the output speed sensor (NC).

While the vehicle is operating in 2nd, 3rd, 4th, 5th or 6th gear with the shift lever in D, if the input shaft speed is less than 300 rpm*1 although the output shaft speed is more than 1000 rpm, the TCM will turn on the MIL and store the DTC.

*1: Pulse is not output or is irregularly output.

MONITOR STRATEGY

|

Related DTCs |

P0715: Input Speed sensor (NT)/Range check P0717: Input Speed sensor (NT)/Verify pulse input |

|

Required sensors/Components |

Input Speed sensor (NT), Output Speed sensor (NC) |

|

Frequency of operation |

Continuous |

|

Duration |

P0715: 4.5 seconds P0717: 5 seconds |

|

MIL operation |

Immediate |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

P0715:

|

Battery voltage |

8 V or more |

|

Ignition switch |

ON |

|

Starter |

OFF |

P0717:

|

The monitor will run whenever this DTC is not present. |

P0746, P0748: Shift solenoid valve SL1 P0776, P0778: Shift solenoid valve SL2 P0796, P0798: Shift solenoid valve SL3 P2808, P2810: Shift solenoid valve SL2 |

|

Shift change |

Shift change is completed before starting next shift change operation |

|

TCM selected gear |

2nd, 3rd, 4th, 5th or 6th |

|

Output shaft speed |

1000 rpm or more |

|

Park/neutral position switch |

OFF |

|

R switch |

OFF |

|

Engine |

Running |

|

Transmission range switch fail (P0705) |

Not detected |

|

Turbine speed sensor range check fail (P0715) |

Not detected |

|

Battery voltage |

8 V or more |

|

Ignition switch |

ON |

|

Starter |

OFF |

TYPICAL MALFUNCTION THRESHOLDS

P0715:

|

Sensor voltage |

Less than 0.1 V, or more than 1.9 V |

P0717:

|

Turbine speed sensor revolution |

Less than 300 rpm |

COMPONENT OPERATING RANGE

|

Input speed sensor (NT) |

Turbine speed is equal to engine speed with lock-up ON |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Perform the universal trip to clear permanent DTCs (See page

![2016 MY Sienna [12/2015 - 08/2016]; U660E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif) ).

).

HINT:

Using the Techstream to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may be discovered before parts or wiring is disturbed. Reading the Data List information early in troubleshooting is one way to save diagnostic time.

NOTICE:

In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

- Warm up the engine.

- Turn the ignition switch off.

- Connect the Techstream to the DLC3.

- Turn the ignition switch to ON.

- Turn the Techstream on.

- Enter the following menus: Powertrain / ECT / Data List / All Data.

-

According to the display on the Techstream, read the Data List.

ECT

Tester Display

Measurement Item/Range

Normal Condition

Diagnostic Note

SPD (NT)

Input turbine speed/

Min.: 0 rpm, Max.: 12750 rpm

Lock-up is

-

ON (After warming up the engine):

Input turbine speed (NT) is equal to engine speed

-

OFF (idling with shift lever in N):

Input turbine speed (NT) is nearly equal to engine speed

Data is displayed in increments of 50 rpm

HINT:

- SPD (NT) is always 0 while driving: Open or short in the sensor or circuit.

- SPD (NT) is always more than 0 and less than 300 rpm while driving the vehicle at 50 km/h (31 mph) or more: Sensor trouble, improper installation, or intermittent connection trouble of the circuit.

-

ON (After warming up the engine):

PROCEDURE

|

1. |

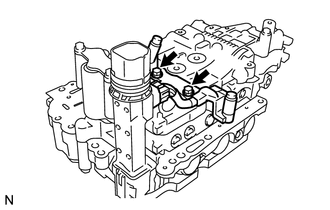

INSPECT TRANSMISSION REVOLUTION SENSOR (SENSOR INSTALLATION) |

(a) Remove the valve body assembly.

|

(b) Make sure that the connector is properly connected, and check the transmission revolution sensor installation. OK: The installation bolt is tightened properly and there is no clearance between the sensor and transmission valve body. |

|

| NG |

|

|

|

2. |

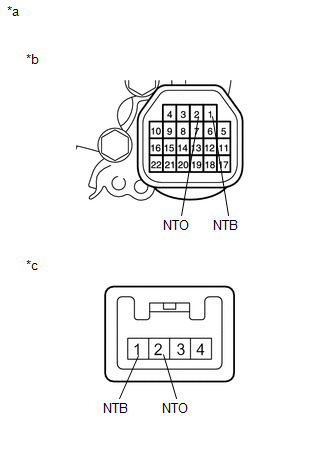

INSPECT TRANSMISSION WIRE |

|

(a) Remove the TCM. |

|

(b) Disconnect the speed sensor connector from the transmission wire.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (NTB) - 1 (NTB) |

Always |

Below 1 Ω |

|

2 (NTO) - 2 (NTO) |

Always |

Below 1 Ω |

|

1 (NTB) - Body ground |

Always |

10 kΩ or higher |

|

2 (NTO) - Body ground |

Always |

10 kΩ or higher |

|

1 (NTB) - All other terminals except 2 (NTO) |

Always |

10 kΩ or higher |

|

2 (NTO) - All other terminals except 1 (NTB) |

Always |

10 kΩ or higher |

Text in Illustration

|

*a |

Component without harness connected: (Transmission Wire) |

|

*b |

TCM Side: |

|

*c |

Sensor Side: |

| NG |

|

|

|

3. |

REPLACE TRANSMISSION REVOLUTION SENSOR |

(a) Replace transmission revolution sensor (See page

![2016 MY Sienna [12/2015 - 08/2016]; U660E (AUTOMATIC TRANSMISSION / TRANSAXLE): SPEED SENSOR(When Not Using the Engine Support Bridge): REMOVAL](/t3Portal/stylegraphics/info.gif) ).

).

|

|

4. |

CHECK DTC OUTPUT |

(a) Connect the Techstream to the DLC3.

(b) Start the engine and turn the Techstream on.

(c) Enter the following menus: Powertrain / ECT / Trouble Codes / Clear.

HINT:

Write down the currently output DTCs before clearing them.

(d) Perform the monitor drive pattern (See page

![2016 MY Sienna [12/2015 - 08/2016]; U660E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: MONITOR DRIVE PATTERN](/t3Portal/stylegraphics/info.gif) ).

).

(e) Enter the following menus: Powertrain / ECT / Trouble Code.

(f) Read the DTCs using the Techstream.

Result

|

Result |

Proceed to |

|---|---|

|

DTC not output |

A |

|

P0715 and/or P0717 is output |

B |

| A |

|

END |

| B |

|

|

|

|