| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000VIFK |

| Model Year Start: 2016 | Model: Sienna | Prod Date Range: [12/2015 - 08/2016] |

| Title: 2GR-FE COOLING: WATER PUMP: INSTALLATION; 2016 MY Sienna [12/2015 - 08/2016] | ||

INSTALLATION

PROCEDURE

1. INSTALL WATER PUMP ASSEMBLY

(a) Wipe the surface of the timing chain cover where a new water pump gasket and the water pump assembly will be installed.

|

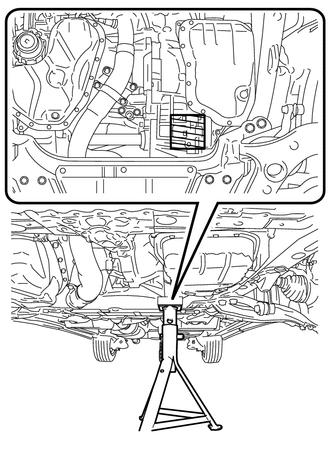

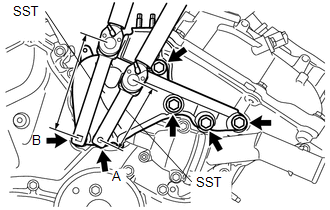

(b) Install a new water pump gasket and the water pump assembly together with the water pump pulley with the 16 bolts. Torque: Bolt A : 21 N·m {214 kgf·cm, 15 ft·lbf} Bolts B and C : 11 N·m {112 kgf·cm, 8 ft·lbf} NOTICE:

|

|

2. INSTALL WATER PUMP PULLEY

(a) Temporarily install the water pump pulley with the 4 bolts.

|

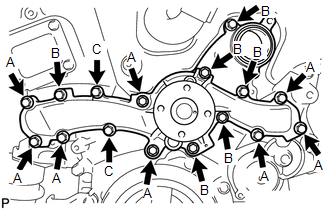

(b) Using SST, hold the water pump pulley. SST: 09960-10010 09962-01000 09963-00700 |

|

(c) Using SST and union nut wrench, tighten the 4 bolts.

SST: 09961-00950

Torque:

without SST :

21 N·m {214 kgf·cm, 15 ft·lbf}

with SST :

11 N·m {112 kgf·cm, 8 ft·lbf}

HINT:

- Use a torque wrench with a fulcrum length of 180 mm (7.09 in.).

- The effective length of SST (09961-00950) is 150 mm (5.91 in.).

- The effective length of union nut wrench is 22 mm (0.866 in.).

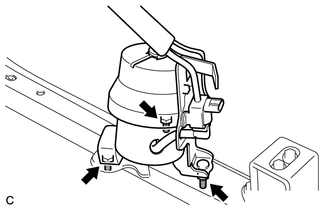

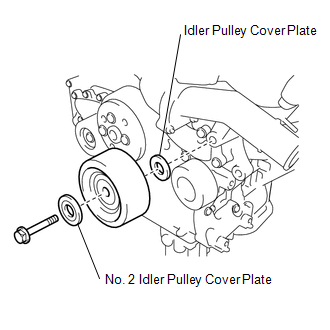

3. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

|

(a) Install the idler pulley cover plate, No. 2 idler pulley cover plate and No. 2 idler pulley sub-assembly with the bolt. Torque: 54 N·m {551 kgf·cm, 40 ft·lbf} HINT: Plate diameter: Idler pulley cover plate: 33.6 mm (1.32 in.) No. 2 idler pulley cover plate: 37.8 mm (1.49 in.) |

|

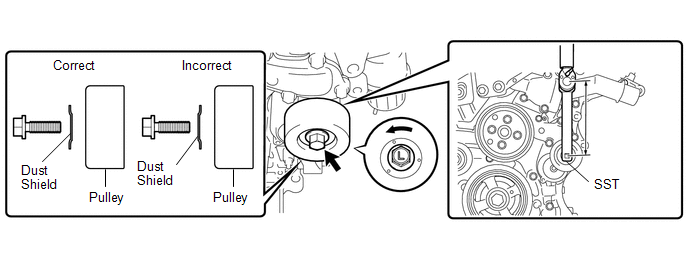

4. INSTALL V-RIBBED BELT TENSIONER PULLEY

(a) Clean and degrease the bolt seating surface and fastening surface.

(b) Install the V-ribbed belt tensioner pulley and dust shield with the bolt.

SST: 09961-00950

Torque:

without SST :

48 N·m {489 kgf·cm, 35 ft·lbf}

with SST :

26 N·m {265 kgf·cm, 19 ft·lbf}

NOTICE:

- Be careful when tightening the bolt because its thread is left-handed.

- Install the dust shield in the direction shown in the illustration. Failure to do so may cause looseness.

- Make sure to use the removed bolt. (Do not use another bolt even if it is the same size.)

HINT:

- Use a torque wrench with a fulcrum length of 180 mm (7.09 in.).

- The effective length of SST (09961-00950) is 150 mm (5.91 in.).

(c) Install the 5 mm bi-hexagon wrench.

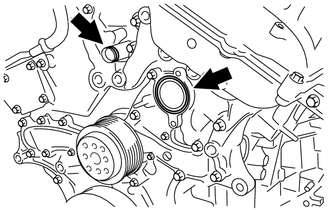

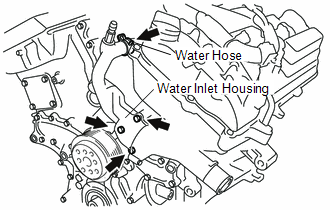

5. INSTALL WATER INLET HOUSING

|

(a) Install a new water inlet housing gasket and water outlet pipe O-ring. |

|

|

(b) Install the water inlet housing with the 2 bolts and nut. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} NOTICE: Be careful not to allow the O-ring to get caught between the parts. |

|

(c) Connect the water hose.

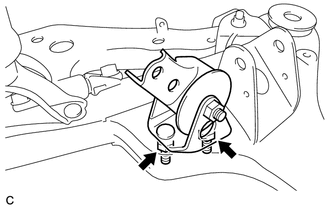

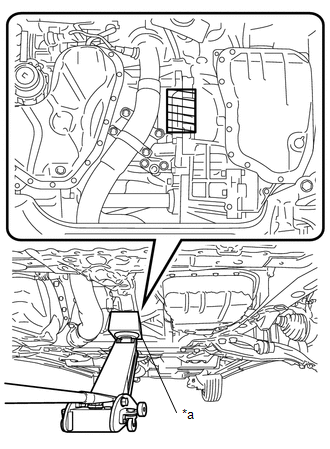

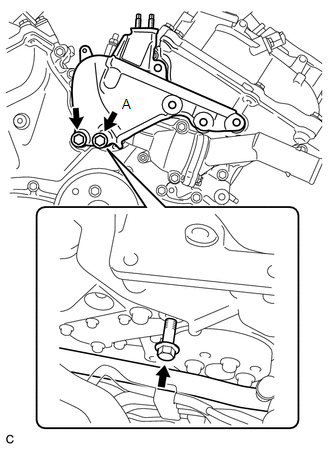

6. INSTALL NO. 1 FRONT ENGINE MOUNTING BRACKET LH

(a) Place a wooden block between a jack and the engine.

|

*a |

Wooden Block |

|

Placement Position |

NOTICE:

Make sure to set a jack as shown in the illustration. Do not place the jack on the oil pan.

(b) Jack up the engine slightly, and support the specified location with a safety stand.

|

Placement Position |

NOTICE:

Do not jack up the engine excessively.

|

(c) Temporarily install the No. 1 front engine mounting bracket LH with the 2 bolts. HINT: Lift the engine so that the bolt (A) passes above the No. 1 cooler refrigerant suction pipe. |

|

(d) Lower the engine.

NOTICE:

When lowering the jack, align the stud bolts of the engine mounting insulators with the bolt holes of the front frame assembly.

|

(e) Install the 4 bolts. Torque: 54 N·m {551 kgf·cm, 40 ft·lbf} |

|

(f) Using SST, tighten the bolt (A).

SST: 09249-37010

Torque:

without SST :

54 N·m {551 kgf·cm, 40 ft·lbf}

with SST :

39 N·m {398 kgf·cm, 29 ft·lbf}

HINT:

- Use a torque wrench with a fulcrum length of 260 mm (10.2 in.).

- The effective length of SST (09249-37010) is 100 mm (3.94 in.).

(g) Using SST, tighten the bolt (B).

SST: 09961-00950

Torque:

without SST :

54 N·m {551 kgf·cm, 40 ft·lbf}

with SST :

34 N·m {347 kgf·cm, 25 ft·lbf}

HINT:

- Use a torque wrench with a fulcrum length of 260 mm (10.2 in.).

- The effective length of SST (09961-00950) is 150 mm (5.91 in.).

7. CONNECT NO. 2 RADIATOR HOSE

8. INSTALL NO. 2 ENGINE MOUNTING STAY RH

9. INSTALL ENGINE MOVING CONTROL ROD

10. INSTALL ENGINE MOVING CONTROL ROD BRACKET

11. INSTALL NO. 2 ENGINE MOUNTING STAY RH

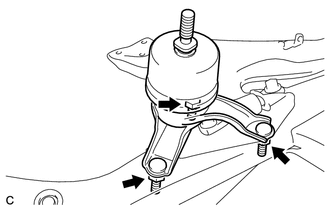

12. INSTALL REAR ENGINE MOUNTING INSULATOR ASSEMBLY

|

(a) Install the 2 nuts. Torque: 52 N·m {530 kgf·cm, 38 ft·lbf} |

|

(b) Install the hole plugs.

13. INSTALL ENGINE MOUNTING INSULATOR RH

|

(a) Install the 3 nuts. Torque: 87 N·m {887 kgf·cm, 64 ft·lbf} |

|

(b) Install the hole plugs.

14. INSTALL FRONT ENGINE MOUNTING INSULATOR ASSEMBLY

|

(a) Install the 3 nuts. Torque: 52 N·m {530 kgf·cm, 38 ft·lbf} |

|

(b) Install the hole plugs.

15. INSTALL FAN AND GENERATOR V BELT

16. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Torque:

5.4 N·m {55 kgf·cm, 48 in·lbf}

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

17. ADD ENGINE COOLANT

18. INSPECT FOR COOLANT LEAK

19. INSTALL NO. 2 ENGINE UNDER COVER (for AWD)

20. INSTALL NO. 1 ENGINE UNDER COVER

21. INSTALL V-BANK COVER SUB-ASSEMBLY

|

|

|

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE ENGINE MECHANICAL: ENGINE ASSEMBLY: INSTALLATION+](/t3Portal/stylegraphics/info.gif)