| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000VIEY |

| Model Year Start: 2016 | Model: Sienna | Prod Date Range: [12/2015 - 08/2016] |

| Title: 2GR-FE INTAKE / EXHAUST: EXHAUST PIPE(for 4WD): INSTALLATION; 2016 MY Sienna [12/2015 - 08/2016] | ||

INSTALLATION

PROCEDURE

1. INSTALL NO. 2 OXYGEN SENSOR (for Bank 2 Sensor 2)

|

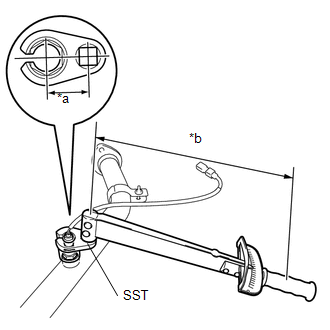

(a) Using SST, install the No. 2 oxygen sensor (for bank 2 sensor 2) to the front exhaust pipe assembly. Text in Illustration

SST: 09224-00010 Torque: Specified tightening torque : 44 N·m {449 kgf·cm, 32 ft·lbf} NOTICE: If a component has been dropped or subjected to a strong impact, replace No. 2 oxygen sensor (for bank 2 sensor 2). |

|

2. INSTALL OXYGEN SENSOR (for Bank 1 Sensor 2)

|

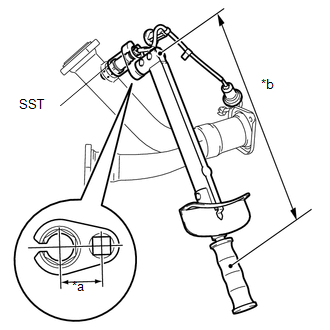

(a) Using SST, install the oxygen sensor (for bank 1 sensor 2) to the front No. 3 exhaust pipe sub-assembly. Text in Illustration

SST: 09224-00010 Torque: Specified tightening torque : 44 N·m {449 kgf·cm, 32 ft·lbf} NOTICE: If a component has been dropped or subjected to a strong impact, replace oxygen sensor (for bank 1 sensor 2). |

|

3. INSTALL FRONT EXHAUST PIPE ASSEMBLY

(a) Install a new gasket to the front exhaust pipe assembly.

(b) Install the front exhaust pipe assembly to the exhaust manifold sub-assembly LH (TWC: front catalyst) with 2 new nuts.

Torque:

62 N·m {632 kgf·cm, 46 ft·lbf}

(c) Connect the exhaust pipe clamp to the No. 1 exhaust pipe support bracket and tighten the bolt.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

(d) Engage the 6 clamps to connect the oxygen sensor (for bank 2 sensor 2) wire to the 2 wire harness clamp brackets.

(e) Connect the oxygen sensor (for bank 2 sensor 2) connector.

4. INSTALL CENTER EXHAUST PIPE ASSEMBLY

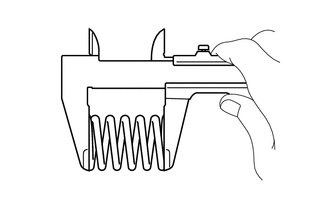

(a) Inspect the free length.

|

(1) Using a vernier caliper, measure the free length of the compression spring. Free Length of Compression Spring:

If the length is not as specified, replace the compression spring. |

|

|

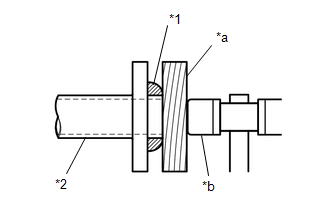

(b) Using a plastic hammer and a wooden block, tap in a new gasket until its surface is flush with the front No. 3 exhaust pipe sub-assembly. Text in Illustration

NOTICE:

|

|

|

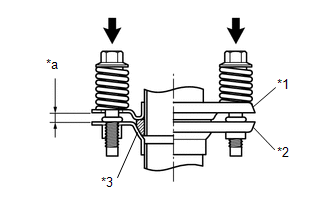

(c) Install the center exhaust pipe sub-assembly (TWC: rear catalyst) to the front No. 3 exhaust pipe sub-assembly with the 2 compression springs and 2 bolts. Text in Illustration

Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} NOTICE: After the installation, check that the gaps between the flanges of the center exhaust pipe sub-assembly (TWC: rear catalyst) and front No. 3 exhaust pipe sub-assembly are consistent front-to-rear and left-to-right. |

|

(d) Inspect the free length.

|

(1) Using a vernier caliper, measure the free length of the compression spring. Free Length of Compression Spring:

If the length is not as specified, replace the compression spring. |

|

|

(e) Using a plastic hammer and a wooden block, tap in a new gasket until its surface is flush with the center No. 2 exhaust pipe sub-assembly. Text in Illustration

NOTICE:

|

|

|

(f) Install the center exhaust pipe sub-assembly (TWC: rear catalyst) to the center No. 2 exhaust pipe sub-assembly with the 2 compression springs and 2 bolts. Text in Illustration

Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} NOTICE: After the installation, check that the gaps between the flanges of the center exhaust pipe sub-assembly (TWC: rear catalyst) and center No. 2 exhaust pipe sub-assembly are consistent front-to-rear and left-to-right. |

|

(g) Install 2 new gaskets to the center exhaust pipe assembly and the front exhaust pipe assembly.

(h) Connect the 2 exhaust pipe supports to install the center exhaust pipe assembly to the vehicle.

(i) Install the center exhaust pipe assembly to the front exhaust pipe assembly with 2 new bolts and 2 new nuts.

Torque:

Bolt :

43 N·m {438 kgf·cm, 32 ft·lbf}

Nut :

62 N·m {632 kgf·cm, 46 ft·lbf}

(j) Engage the clamp to connect the oxygen sensor (for bank 1 sensor 2) wire to the vehicle.

(k) Pass the connector through the hole to the inside of the vehicle and install the grommet of the oxygen sensor (for bank 1 sensor 2) wire.

(l) Connect the oxygen sensor (for bank 1 sensor 2) connector.

5. INSTALL TAIL EXHAUST PIPE ASSEMBLY

(a) Install a new gasket to the center exhaust pipe assembly.

(b) Connect the 4 exhaust pipe supports to install the tail exhaust pipe assembly to the vehicle.

(c) Install the tail exhaust pipe assembly to the center exhaust pipe assembly with 2 new bolts.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

6. INSTALL INSTRUMENT PANEL FINISH PANEL END LH

(a) Engage the 3 guides and install the instrument panel finish panel end LH.

(b) Install the clip.

7. INSPECT FOR EXHAUST GAS LEAK

|

|

|

![2016 MY Sienna [12/2015 - 08/2016]; INTRODUCTION: REPAIR INSTRUCTION: PRECAUTION](/t3Portal/stylegraphics/info.gif)