| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000VIEV |

| Model Year Start: 2016 | Model: Sienna | Prod Date Range: [12/2015 - 08/2016] |

| Title: 2GR-FE INTAKE / EXHAUST: EXHAUST MANIFOLD: INSTALLATION; 2016 MY Sienna [12/2015 - 08/2016] | ||

INSTALLATION

PROCEDURE

1. INSTALL NO. 2 AIR FUEL RATIO SENSOR (for Bank 2 Sensor 1)

|

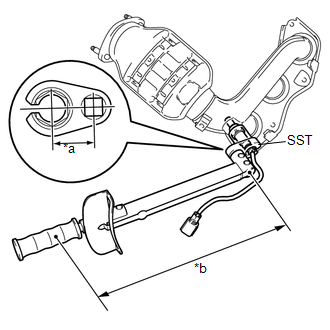

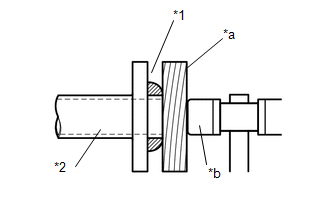

(a) Using SST, install the No. 2 air fuel ratio sensor (for Bank 2 Sensor 1) to the front exhaust manifold sub-assembly LH. Text in Illustration

SST: 09224-00010 Torque: Specified tightening torque : 44 N·m {449 kgf·cm, 32 ft·lbf} NOTICE: If a component has been dropped or subjected to a strong impact, replace No. 2 air fuel ratio sensor (for Bank 2 Sensor 1). |

|

2. INSTALL EXHAUST MANIFOLD TO HEAD GASKET LH

(a) Install a new exhaust manifold to head gasket LH.

3. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH

|

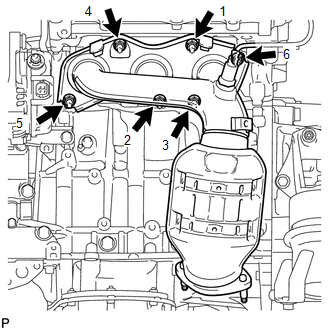

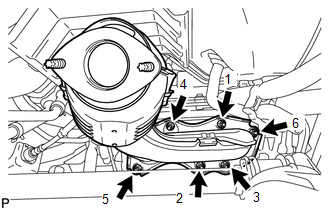

(a) Temporarily install the exhaust manifold sub-assembly LH with the 6 nuts. |

|

(b) Using a 12 mm deep socket wrench, tighten the 6 nuts in the order shown in the illustration.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

4. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR

|

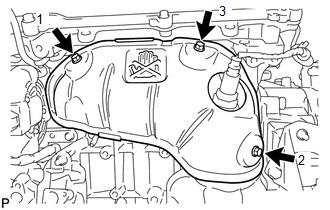

(a) Install the No. 2 exhaust manifold heat insulator, tightening the 3 bolts in the order shown in the illustration. Torque: 8.5 N·m {87 kgf·cm, 75 in·lbf} |

|

(b) Connect the air fuel ratio sensor (for Bank 2 Sensor 1) connector and engage the 2 harness clamps.

5. INSTALL NO. 2 MANIFOLD STAY

|

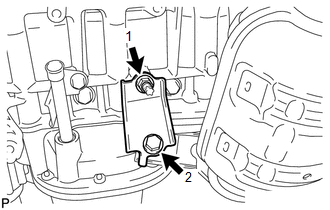

(a) Install the No. 2 manifold stay, tightening the bolt and nut in the order shown in the illustration. Torque: 34 N·m {347 kgf·cm, 25 ft·lbf} |

|

6. INSTALL NO. 2 OIL LEVEL DIPSTICK GUIDE

(a) Install a new O-ring to the No. 2 oil level dipstick guide.

(b) Apply a light coat of engine oil to the O-ring.

(c) Push in the No. 2 oil level dipstick guide end into the oil level dipstick guide.

(d) Install the No. 2 oil level dipstick guide with the bolt.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

(e) Install the oil level dipstick.

7. INSTALL AIR FUEL RATIO SENSOR (for Bank 1 Sensor 1)

8. INSTALL EXHAUST MANIFOLD TO HEAD GASKET

(a) Install a new exhaust manifold to head gasket.

9. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH

|

(a) Temporarily install the exhaust manifold sub-assembly RH with the 6 nuts. |

|

(b) Using a 12 mm deep socket wrench, tighten the 6 nuts in the order shown in the illustration.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

(c) Connect the air fuel ratio sensor (for Bank 1 Sensor 1) connector and engage the 2 harness clamps.

10. INSTALL MANIFOLD STAY

(a) Install the manifold stay with the bolt and nut.

Torque:

Bolt :

34 N·m {347 kgf·cm, 25 ft·lbf}

Nut :

35 N·m {357 kgf·cm, 26 ft·lbf}

11. INSTALL FRONT EXHAUST PIPE ASSEMBLY (for 2WD)

(a) Inspect the free length.

|

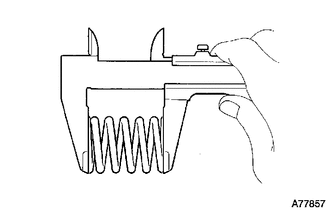

(1) Using a vernier caliper, measure the free length of the compression spring. Free Length of Compression Spring:

If the length is not as specified, replace the compression spring. |

|

|

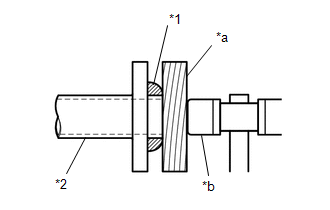

(b) Using a plastic hammer and a wooden block, tap in a new gasket until its surface is flush with the front exhaust pipe assembly. Text in Illustration

NOTICE:

|

|

(c) Install 2 new gaskets to the front exhaust pipe assembly.

(d) Install the front exhaust pipe assembly to the exhaust manifold sub-assembly LH (TWC: front catalyst) and exhaust manifold sub-assembly RH (TWC: front catalyst) with 4 new nuts.

Torque:

62 N·m {632 kgf·cm, 46 ft·lbf}

|

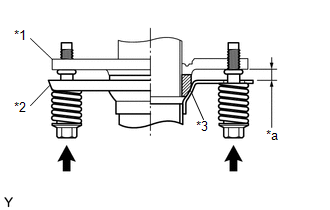

(e) Connect the front exhaust pipe assembly to the center exhaust pipe sub-assembly (TWC: rear catalyst) with the 2 compression springs and 2 bolts. Text in Illustration

Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} NOTICE: After the installation, check that the gaps between the flanges of the front exhaust pipe assembly and center exhaust pipe assembly are consistent front-to-rear and left-to-right. |

|

(f) Connect the exhaust pipe clamp to the No. 1 exhaust pipe support bracket and tighten the bolt.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

(g) Engage the 6 clamps to connect the oxygen sensor (for bank 2 sensor 2) wire to the 2 wire harness clamp brackets.

(h) Connect the oxygen sensor (for bank 2 sensor 2) connector.

(i) Pass the connector through the hole to the inside of the vehicle and install the grommet of the oxygen sensor (for bank 1 sensor 2) wire.

(j) Connect the oxygen sensor (for bank 1 sensor 2) connector.

12. INSTALL FRONT EXHAUST PIPE ASSEMBLY (for AWD)

(a) Install a new gasket to the front exhaust pipe assembly.

(b) Install the front exhaust pipe assembly to the exhaust manifold sub-assembly LH (TWC: front catalyst) with the 2 nuts.

Torque:

62 N·m {632 kgf·cm, 46 ft·lbf}

(c) Inspect the free length.

|

(1) Using a vernier caliper, measure the free length of the compression spring. Free Length of Compression Spring:

If the length is not as specified, replace the compression spring. |

|

|

(d) Using a plastic hammer and a wooden block, tap in a new gasket until its surface is flush with the front No. 3 exhaust pipe sub-assembly. Text in Illustration

NOTICE:

|

|

(e) Install 2 new gaskets to the front No. 3 exhaust pipe sub-assembly.

(f) Install the front No. 3 exhaust pipe sub-assembly to the exhaust manifold sub-assembly RH (TWC: front catalyst) and front exhaust pipe assembly with 2 new nuts and 2 new bolts.

Torque:

Bolt :

43 N·m {438 kgf·cm, 32 ft·lbf}

Nut :

62 N·m {632 kgf·cm, 46 ft·lbf}

|

(g) Connect the front No. 3 exhaust pipe sub-assembly to the center exhaust pipe sub-assembly (TWC: rear catalyst) with the 2 compression springs and 2 bolts. Text in Illustration

Torque: 43 N·m {438 kgf·cm, 32 ft·lbf} NOTICE: After the installation, check that the gaps between the flanges of the front No. 3 exhaust pipe sub-assembly and center exhaust pipe assembly are consistent front-to-rear and left-to-right. |

|

(h) Connect the exhaust pipe clamp to No. 1 exhaust pipe support bracket and tighten the bolt.

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

(i) Engage the 6 clamps to connect the oxygen sensor (for bank 2 sensor 2) wire to the 2 wire harness clamp brackets.

(j) Connect the oxygen sensor (for bank 2 sensor 2) connector.

(k) Pass the connector through the hole to the inside of the vehicle and install the grommet of the oxygen sensor (for bank 1 sensor 2) wire.

(l) Connect the oxygen sensor (for bank 1 sensor 2) connector.

13. INSTALL PROPELLER WITH CENTER BEARING SHAFT ASSEMBLY (for AWD)

14. INSTALL NO. 2 ENGINE UNDER COVER (for AWD)

(a) Install the No. 2 engine under cover with the 2 bolts, 2 screws and clip.

15. INSTALL NO. 1 ENGINE UNDER COVER

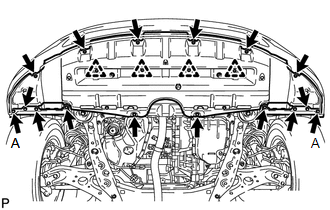

|

(a) Install the No. 1 engine under cover with the 2 bolts, 6 screws and 4 clips. |

|

(b) Install the front wheel opening extension pad RH and front wheel opening extension pad LH with the 8 screws.

Torque:

Screw A :

7.0 N·m {71 kgf·cm, 62 in·lbf}

16. INSTALL INSTRUMENT PANEL FINISH PANEL END LH

17. INSTALL V-BANK COVER SUB-ASSEMBLY

18. INSTALL RADIATOR ASSEMBLY

19. INSPECT FOR EXHAUST GAS LEAK

|

|

|

![2016 MY Sienna [12/2015 - 08/2016]; INTRODUCTION: REPAIR INSTRUCTION: PRECAUTION](/t3Portal/stylegraphics/info.gif)