| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000VIDB |

| Model Year Start: 2016 | Model: Sienna | Prod Date Range: [12/2015 - 08/2016] |

| Title: 2GR-FE ENGINE MECHANICAL: CYLINDER BLOCK: DISASSEMBLY; 2016 MY Sienna [12/2015 - 08/2016] | ||

DISASSEMBLY

PROCEDURE

1. REMOVE PISTON SUB-ASSEMBLY WITH CONNECTING ROD

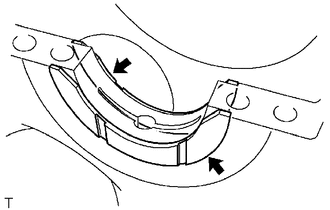

(a) Check that the matchmarks on the connecting rod sub-assembly and connecting rod cap are aligned.

HINT:

The matchmarks on the connecting rod sub-assembly and connecting rod cap are guides for the correct reassembly.

(b) Remove the 2 connecting rod cap bolts.

Text in Illustration

|

Engine Front |

|

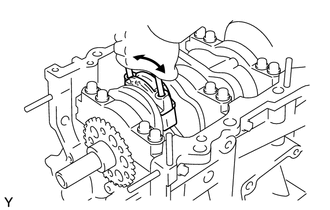

(c) Using the 2 removed connecting rod cap bolts, remove the connecting rod cap and lower bearing by wiggling the connecting rod cap right and left. HINT: Keep the lower bearing inserted to the connecting rod cap. |

|

|

(d) Using a ridge reamer, remove all the carbon from the top of the cylinder. Text in Illustration

|

|

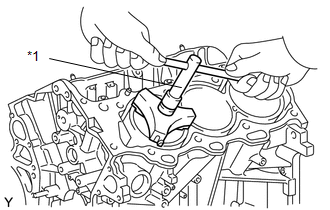

(e) Push the piston, connecting rod assembly and upper bearing through the top of the cylinder block.

HINT:

- Keep the bearing, connecting rod and cap together.

- Arrange the piston and connecting rod assemblies in the correct order.

2. REMOVE CONNECTING ROD BEARING

HINT:

Arrange the removed parts in the correct order.

3. REMOVE PISTON RING SET

|

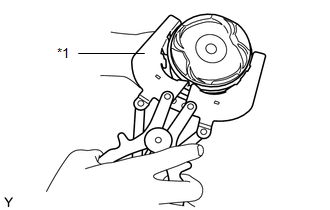

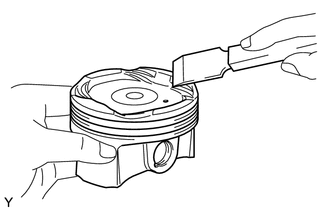

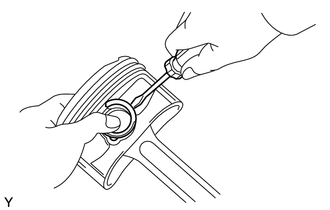

(a) Using a piston ring expander, remove the 2 compression rings. Text in Illustration

|

|

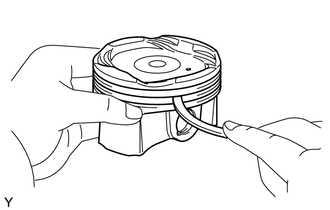

(b) Remove the oil ring expander and 2 side rails by hand.

HINT:

Arrange the removed parts in the correct order.

4. REMOVE PISTON

|

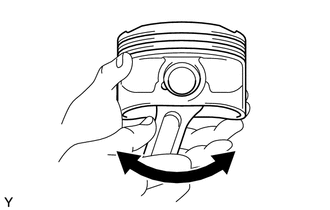

(a) Check the fitting condition between the piston and piston pin. (1) Try to move the piston back and forth on the piston pin. If any movement is felt, replace the piston and pin as a set. |

|

(b) Disconnect the connecting rod from the piston.

(1) Using a screwdriver, pry off the piston pin hole snap rings from the piston.

|

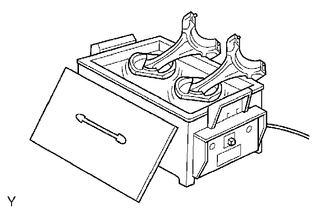

(2) Gradually heat the piston to approximately 80°C (176°F). |

|

|

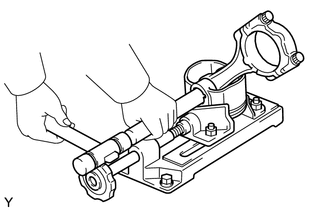

(3) Using a brass bar and a plastic hammer, lightly tap out the piston pin and remove the connecting rod sub-assembly. HINT:

|

|

|

(c) Using a gasket scraper, remove the carbon from the piston top. |

|

|

(d) Using a groove cleaning tool or broken ring, clean the piston ring grooves. |

|

|

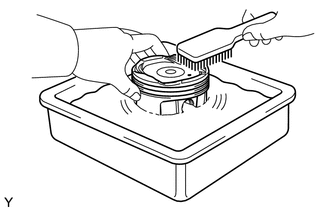

(e) Using solvent and a brush, thoroughly clean the piston. NOTICE: Do not use a wire brush. |

|

5. REMOVE CRANKSHAFT

|

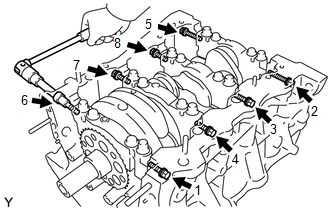

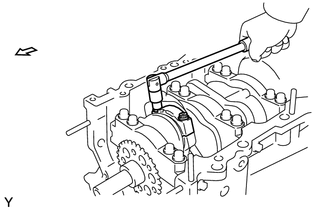

(a) Uniformly loosen and remove the 8 crankshaft bearing cap bolts and the 8 seal washers in several steps and in the sequence shown in the illustration. |

|

|

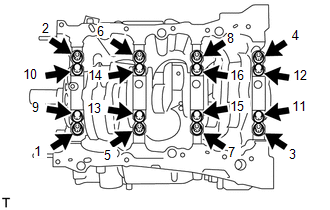

(b) Uniformly loosen the 16 crankshaft bearing cap bolts, in several steps and in the sequence shown in the illustration. |

|

|

(c) Using a screwdriver, pry out the crankshaft bearing caps. Remove the 4 crankshaft bearing caps and lower crankshaft bearings. Text in Illustration

NOTICE:

|

|

(d) Remove the crankshaft.

6. REMOVE CRANKSHAFT BEARING

(a) Remove the upper crankshaft bearings and lower crankshaft bearings.

HINT:

Arrange the removed parts in the correct order.

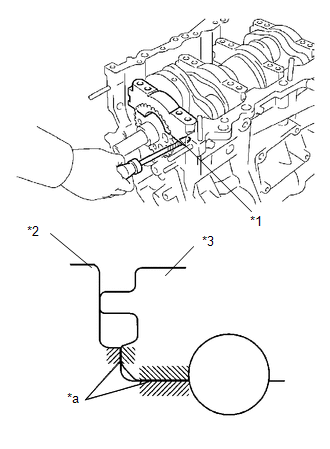

7. REMOVE CRANKSHAFT THRUST WASHER SET

|

(a) Remove the upper crankshaft thrust washers from the cylinder block sub-assembly. |

|

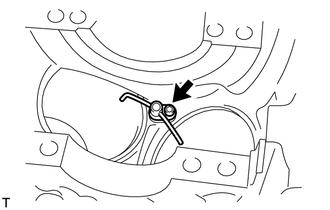

8. REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY

|

(a) Using a 5 mm hexagon wrench, remove the 3 bolts and No. 1 oil nozzle sub-assemblies. |

|

(b) Check the 3 oil nozzles for damage or clogging.

If necessary, replace the No. 1 oil nozzle sub-assembly.

9. CLEAN CYLINDER BLOCK

|

|

|