| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000VICQ |

| Model Year Start: 2016 | Model: Sienna | Prod Date Range: [12/2015 - 08/2016] |

| Title: 2GR-FE ENGINE MECHANICAL: CAMSHAFT: INSTALLATION; 2016 MY Sienna [12/2015 - 08/2016] | ||

INSTALLATION

PROCEDURE

1. INSTALL NO. 3 CAMSHAFT

(a) Apply a light coat of engine oil to the No. 3 camshaft journals and camshaft housing sub-assembly LH.

(b) Install the No. 3 camshaft to the camshaft housing sub-assembly LH.

2. INSTALL NO. 4 CAMSHAFT

(a) Apply a light coat of engine oil to the No. 4 camshaft journals and camshaft housing sub-assembly LH.

(b) Install the No. 4 camshaft to the camshaft housing sub-assembly LH.

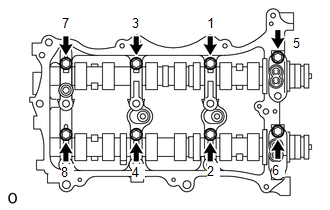

3. INSTALL CAMSHAFT BEARING CAP (for Bank 2)

(a) Apply engine oil to the camshaft bearing caps.

|

(b) Make sure of the marks and numbers on the camshaft bearing caps and place them in each proper position and direction. |

|

|

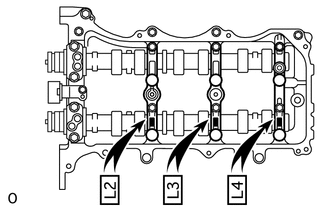

(c) Temporarily tighten the 8 bolts in the order shown in the illustration. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

4. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY LH

|

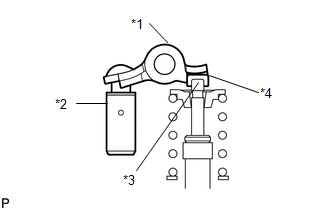

(a) Make sure that the valve rocker arm is installed as shown in the illustration. Text in Illustration

|

|

|

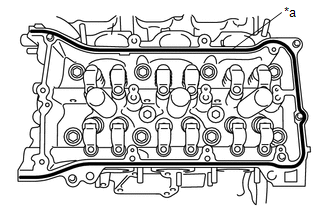

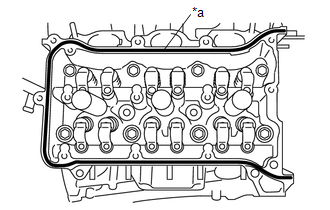

(b) Apply seal packing in a continuous line as shown in the illustration. Text in Illustration

Seal packing: Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Seal diameter: 3.5 to 4.5 mm (0.138 to 0.177 in.) NOTICE:

|

|

|

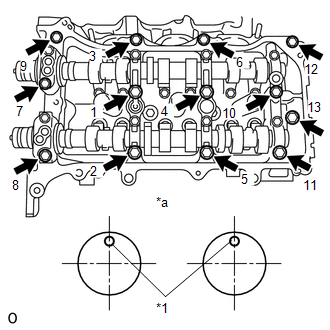

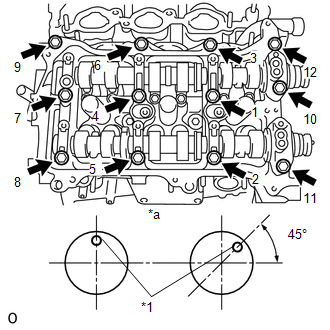

(c) Install the camshaft housing sub-assembly LH and tighten the 13 bolts in the order shown in the illustration. Text in Illustration

Torque: 28 N·m {286 kgf·cm, 21 ft·lbf} NOTICE:

|

|

|

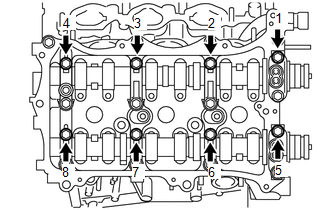

(d) Tighten the 8 bolts in the order shown in the illustration. Torque: 16 N·m {163 kgf·cm, 12 ft·lbf} |

|

5. INSTALL CAMSHAFT

(a) Apply a light coat of engine oil to the camshaft journals and camshaft housing sub-assembly RH.

(b) Install the camshaft to the camshaft housing sub-assembly RH.

6. INSTALL NO. 2 CAMSHAFT

(a) Apply a light coat of engine oil to the No. 2 camshaft journals and camshaft housing sub-assembly RH.

(b) Install the No. 2 camshaft to the camshaft housing sub-assembly RH.

7. INSTALL CAMSHAFT BEARING CAP (for Bank 1)

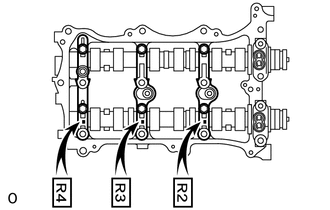

(a) Apply engine oil to the camshaft bearing caps.

|

(b) Make sure of the marks and numbers on the camshaft bearing caps and place them in each proper position and direction. |

|

|

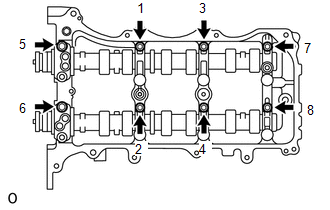

(c) Temporarily tighten the 8 bearing cap bolts in the order shown in the illustration. Torque: 10 N·m {102 kgf·cm, 7 ft·lbf} |

|

8. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY RH

|

(a) Make sure that the No. 1 valve rocker arm sub-assembly is installed as shown in the illustration. Text in Illustration

|

|

|

(b) Apply seal packing in a continuous line as shown in the illustration. Text in Illustration

Seal packing: Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Seal diameter: 3.5 to 4.5 mm (0.138 to 0.177 in.) NOTICE:

|

|

|

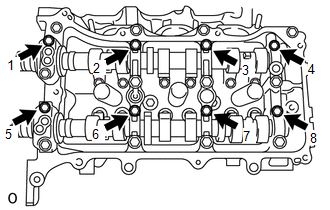

(c) Install the camshaft housing sub-assembly RH and tighten the 12 bolts in the order shown in the illustration. Text in Illustration

Torque: 28 N·m {286 kgf·cm, 21 ft·lbf} NOTICE:

|

|

|

(d) Tighten the 8 bolts in the order shown in the illustration. Torque: 16 N·m {163 kgf·cm, 12 ft·lbf} |

|

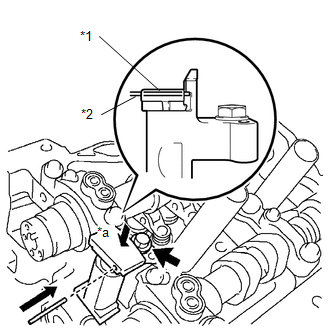

9. INSTALL NO. 3 CHAIN TENSIONER ASSEMBLY

|

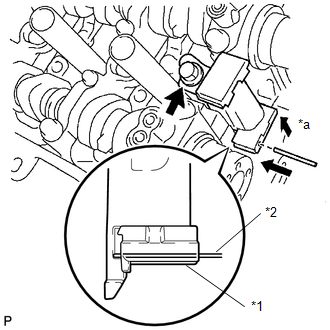

(a) Install the No. 3 chain tensioner assembly with the bolt. Torque: 21 N·m {214 kgf·cm, 15 ft·lbf} |

|

(b) While pushing in the tensioner, insert a pin of 1.0 mm (0.0394 in.) diameter into the hole to hold it.

Text in Illustration

|

*1 |

Plunger |

|

*2 |

Pin |

|

*a |

Push |

10. INSTALL CAMSHAFT TIMING GEARS AND NO. 2 CHAIN (for Bank 2)

|

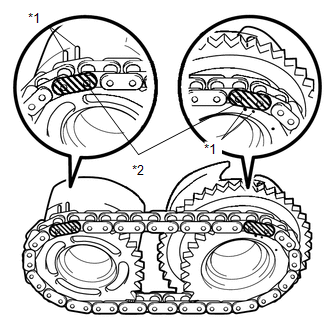

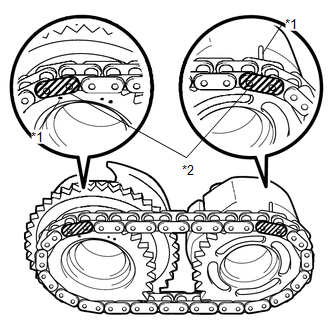

(a) Align the mark plates (yellow) with the timing marks of the camshaft timing gear assemblies as shown in the illustration. Text in Illustration

|

|

(b) Apply a light coat of engine oil to the bolt threads and bolt-seating surface.

(c) Align the knock pin of the camshaft with the pin hole of the camshaft timing gear assembly. Install the camshaft timing gear assembly and camshaft timing exhaust gear LH with the No. 2 chain sub-assembly installed.

|

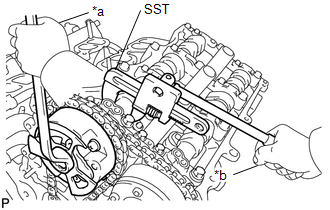

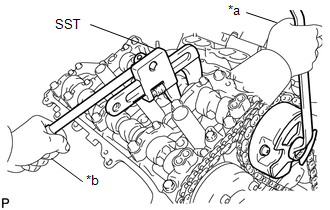

(d) Using SST to hold the hexagonal portion of each camshaft, tighten the flange bolts of the camshaft timing gear assembly and the camshaft timing exhaust gear assembly LH. Text in Illustration

SST: 09922-10010 Torque: 100 N·m {1020 kgf·cm, 74 ft·lbf} |

|

(e) Remove the pin from the No. 3 chain tensioner assembly.

11. INSTALL NO. 2 CHAIN TENSIONER ASSEMBLY

|

(a) Install the No. 2 chain tensioner assembly with the bolt. Torque: 21 N·m {214 kgf·cm, 15 ft·lbf} |

|

(b) While pushing in the No. 2 chain tensioner assembly, insert a pin of 1.0 mm (0.0394 in.) diameter into the hole to hold it.

Text in Illustration

|

*1 |

Plunger |

|

*2 |

Pin |

|

*a |

Push |

12. INSTALL CAMSHAFT TIMING GEARS AND NO. 2 CHAIN (for Bank 1)

|

(a) Align the mark plates (yellow) with the timing marks of the camshaft timing gear assemblies as shown in the illustration. Text in Illustration

|

|

(b) Apply a light coat of engine oil to the bolt threads and bolt-seating surface.

(c) Align the knock pin of the camshaft with the pin hole of the camshaft timing gear assembly. Install the camshaft timing gear assembly and camshaft timing exhaust gear assembly with the No. 2 chain sub-assembly installed.

|

(d) Using SST to hold the hexagonal portion of each camshaft, tighten the flange bolts of the camshaft timing gear assembly and the camshaft timing exhaust gear assembly RH. Text in Illustration

SST: 09922-10010 Torque: 100 N·m {1020 kgf·cm, 74 ft·lbf} |

|

(e) Remove the pin from the No. 2 chain tensioner assembly.

13. INSTALL IDLE SPROCKET ASSEMBLY

14. INSTALL CHAIN SUB-ASSEMBLY

15. INSTALL CHAIN TENSIONER SLIPPER

16. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

17. INSPECT VALVE TIMING

18. INSTALL TIMING GEAR CASE OR TIMING CHAIN CASE OIL SEAL

19. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY

20. INSTALL WATER INLET HOUSING

21. INSTALL FRONT NO. 1 ENGINE MOUNTING BRACKET LH

22. INSTALL OIL PAN SUB-ASSEMBLY

23. INSTALL OIL STRAINER SUB-ASSEMBLY

24. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY

25. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY (for Bank 1)

26. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY LH (for Bank 2)

27. INSTALL CRANKSHAFT PULLEY

28. INSTALL NO. 1 OIL PIPE

29. INSTALL OIL PIPE

30. INSTALL CRANKSHAFT POSITION SENSOR

31. INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

32. INSTALL WATER PUMP PULLEY

33. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

34. INSTALL NO. 2 TIMING GEAR COVER

35. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

36. INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY

37. INSTALL INTAKE MANIFOLD

38. INSTALL IGNITION COIL ASSEMBLY

39. INSTALL ENGINE HANGER

40. REMOVE ENGINE FROM ENGINE STAND

41. INSTALL DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

42. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY (for 2WD)

43. INSTALL AUTOMATIC TRANSAXLE ASSEMBLY (for AWD)

|

|

|

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE ENGINE MECHANICAL: ENGINE UNIT: REASSEMBLY+](/t3Portal/stylegraphics/info.gif)