- Throttle body with motor assembly

- Mass air flow meter

- PCV system

- Air cleaner filter element sub-assembly

- Intake system

- VVT system

- Wire harness or connector

- ECM

| Last Modified: 08-28-2024 | 6.11:8.1.0 | Doc ID: RM100000000VIC0 |

| Model Year Start: 2016 | Model: Sienna | Prod Date Range: [12/2015 - 08/2016] |

| Title: 2GR-FE (ENGINE CONTROL): SFI SYSTEM: P050B; Cold Start Ignition Timing Performance; 2016 MY Sienna [12/2015 - 08/2016] | ||

|

DTC |

P050B |

Cold Start Ignition Timing Performance |

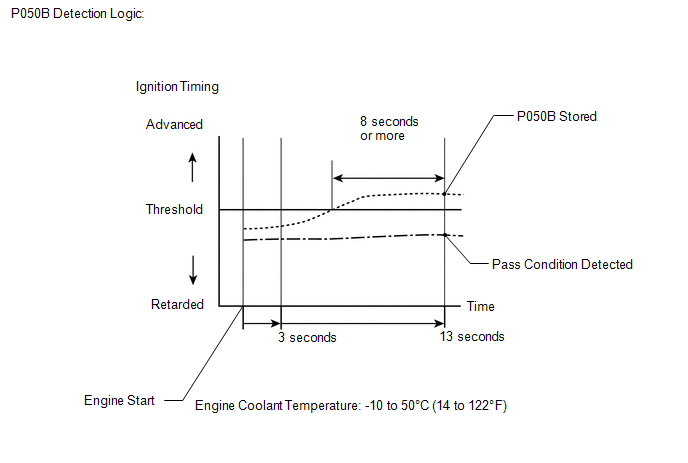

MONITOR DESCRIPTION

This monitor will run when the engine is started at an engine coolant temperature of -10 to 50°C (14 to 122°F). The DTC is stored after the engine idles for 13 seconds (2 trip detection logic).

The DTC is designed to monitor the ignition timing at cold start. When the engine is started at an engine coolant temperature of less than 50°C (122°F), the ECM checks the ignition timing during engine idling. If the ignition timing advances beyond the specified level within 10 seconds, the ECM interprets this as a malfunction. The MIL is illuminated and a DTC is stored when the malfunction is detected in consecutive driving cycles (2 trip detection logic).

NOTICE:

When learning value reset and idle learning after inspections or repairs, the idle speed control learned values are cleared. This DTC cannot be stored with the idle speed control learned values cleared.

HINT:

Idle speed control learning is performed when the engine is warmed up and has been idling for 5 minutes.

|

DTC No. |

DTC Detection Condition |

Trouble Area |

|---|---|---|

|

P050B |

Insufficient ignition timing retard at cold start (2 trip detection logic). |

|

MONITOR STRATEGY

|

Related DTCs |

P050B: Cold start ignition timing performance |

|

Required Sensors/Components (Main) |

Throttle body with motor assembly |

|

Required Sensors/Components (Related) |

Engine coolant temperature sensor Mass air flow meter |

|

Frequency of Operation |

Once per driving cycle |

|

Duration |

10 seconds |

|

MIL Operation |

2 driving cycles |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Monitor runs whenever the following DTCs are not stored |

P0010, P0020 (Camshaft timing oil control valve bank 1, 2) P0011, P0021 (VVT system bank 1, 2 - advance) P0012, P0022 (VVT system bank 1, 2 - retard) P0013, P0023 (Exhaust camshaft timing oil control valve bank 1, 2) P0014, P0024 (Exhaust VVT system bank 1, 2 - advance) P0015, P0025 (Exhaust VVT system bank 1, 2 - retard) P0016, P0018 (VVT system bank 1, 2 - misalignment) P0017, P0019 (Exhaust VVT system bank 1, 2 - misalignment) P0102, P0103 (Mass air flow meter) P0115, P0117, P0118 (Engine coolant temperature sensor) P0120, P0121, P0122, P0123, P0220, P0222, P0223, P2135 (Throttle position sensor) P0125 (Insufficient coolant temperature for closed loop fuel control) P014C, P014D, P014E, P014F, P015A, P015B, P015C, P015D, P2195, P2196, P2197, P2198, P2237, P2238, P2239, P2240, P2241, P2242, P2252, P2253, P2255, P2256 (Air fuel ratio sensor) P0171, P0172, P0174, P0175 (Fuel system) P0300, P0301, P0302, P0303, P0304, P0305, P0306 (Misfire) P0335 (Crankshaft position sensor) P0340, P0342, P0343, P0345, P0347, P0348 (VVT sensor) P0351, P0352, P0353, P0354, P0355, P0356 (Igniter) P0365, P0367, P0368, P0390, P0392, P0393 (Exhaust VVT sensor) P0500 (Vehicle speed sensor) P0705 (Shift lever position switch) P219A, P219B, P219C, P219D, P219E, P219F, P21A0, P21A1 (Air fuel ratio imbalance) |

|

Battery voltage |

8 V or higher |

|

Time after engine start |

3 seconds or more |

|

Starter |

Off |

|

Engine coolant temperature at engine start |

-10°C (14°F) or more |

|

Engine coolant temperature |

-10°C (14°F) or higher, and less than 50°C (122°F) |

|

Engine idling time |

3 seconds or more |

|

Fuel-cut |

Off |

|

Vehicle speed |

Less than 3 km/h (1.875 mph) |

|

Atmospheric pressure |

76 kPa(abs) [570 mmHg(abs)] or higher |

TYPICAL MALFUNCTION THRESHOLDS

|

Accumulated time when ignition timing retard is cut off |

8 seconds or more |

CONFIRMATION DRIVING PATTERN

- Connect the Techstream to the DLC3.

- Turn the ignition switch to ON and turn the Techstream on.

-

Clear DTCs (even if no DTCs are stored, perform the clear DTC procedure) (See page

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE (ENGINE CONTROL): SFI SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif) ).

).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON and turn the Techstream on [A].

- Enter the following menus: Powertrain / Engine / Data List / Coolant Temp.

- Check that "Coolant Temp" in the Data List is within the range of -10 to 50°C (14 to 122°F).

- Start the engine and warm it up until the coolant temperature is the same as the coolant temperature in the freeze frame data.

- Idle the engine for 1 minute or more.

- Enter the following menus: Powertrain / Engine / Trouble Codes [B].

-

Read pending DTC.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P050B.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU's memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, idle the engine for 3 minutes, let the engine cool down, and then perform steps [A] through [B] again.

-

If no pending DTC is output, perform a universal trip and check for permanent DTCs (See page

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE (ENGINE CONTROL): SFI SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif) ).

).

HINT:

- If a permanent DTC is output, the system is malfunctioning.

- If no permanent DTC is output, the system is normal.

WIRING DIAGRAM

Refer to DTC P0102 (See page

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE (ENGINE CONTROL): SFI SYSTEM: P0102,P0103; Mass Air Flow Circuit Low+](/t3Portal/stylegraphics/info.gif) ).

).

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

HINT:

-

DTC P050B may be stored when the engine has the symptoms listed below. If necessary, check the trouble areas listed below.

Symptoms

Factor

Trouble Area

Low idle speed when engine is cold

(immediately after engine start)

Excessive engine friction

- Engine oil deterioration

- Drive belt tension

- A/C compressor

- Generator

Rough idle when engine is cold

(immediately after engine start)

Abnormal combustion

Fuel quality

- Read freeze frame data using the Techstream. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

PROCEDURE

|

1. |

CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P050B) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Trouble Codes.

(e) Read DTCs.

Result

|

Result |

Proceed to |

|---|---|

|

DTC P050B is output |

A |

|

DTC P050B and other DTCs are output |

B |

HINT:

If any DTCs other than P050B are output, troubleshoot those DTCs first.

| B |

|

|

|

2. |

READ VALUE USING TECHSTREAM (FUEL TRIM) |

HINT:

Calculate the total fuel trim values to check the characteristic deviation of the mass air flow meter.

(a) Connect the Techstream to the DLC3.

(b) Start the engine.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Data List / Short FT #1, Long FT #1, Short FT #2 and Long FT #2.

(e) Read the values displayed on the Techstream at engine idle.

(f) Add together the Short FT #1, Long FT #1, Short FT #2 and Long FT #2 values to obtain the total fuel trim.

Standard:

Total of Short FT #1 and Long FT #1, and Short FT #2 and Long FT #2 values is between -20% and 20%.

| NG |

|

|

|

3. |

INSPECT THROTTLE BODY WITH MOTOR ASSEMBLY (THROTTLE VALVE) |

(a) Inspect that there are no deposits around the throttle valve and throttle valve condition.

OK:

No deposits around the throttle valve and throttle valve moves smoothly.

Result

|

Result |

Proceed to |

|---|---|

|

NG |

A |

|

OK |

B |

| B |

|

|

|

4. |

REPAIR OR REPLACE THROTTLE BODY WITH MOTOR ASSEMBLY |

(a) Repair or replace throttle body with motor assembly (See page

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE (ENGINE CONTROL): THROTTLE BODY: REMOVAL](/t3Portal/stylegraphics/info.gif) ).

).

HINT:

Perform "Inspection After Repair" after repairing the throttle body with motor assembly (See page

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE (ENGINE CONTROL): SFI SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif) ).

).

| NEXT |

|

|

5. |

CHECK PCV SYSTEM |

(a) Check the PCV hose connections (See page

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE EMISSION CONTROL: PCV VALVE: COMPONENTS](/t3Portal/stylegraphics/info.gif) ).

).

OK:

PCV valve and hose are connected correctly and are not damaged.

| NG |

|

|

|

6. |

CHECK INTAKE SYSTEM |

(a) Check the intake system for vacuum leaks (See page

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE INTAKE / EXHAUST: INTAKE SYSTEM: ON-VEHICLE INSPECTION](/t3Portal/stylegraphics/info.gif) ).

).

OK:

No leaks from intake system.

| NG |

|

|

|

7. |

CHECK AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY |

(a) Visually check that the air cleaner filter element sub-assembly is not excessively contaminated with dirt or oil.

OK:

The air cleaner filter element sub-assembly is not excessively contaminated with dirt or oil.

| NG |

|

|

|

8. |

PERFORM ACTIVE TEST USING TECHSTREAM (OPERATE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY) |

(a) Operate the VVT system through the Active Test, and check if the VVT system is operating normally.

(1) Perform the Active Test, referring to DTC P0011 inspection procedure (VVT system for intake camshaft) (See page

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE (ENGINE CONTROL): SFI SYSTEM: P0011,P0012,P0021,P0022; Camshaft Position "A" - Timing Over-Advanced or System Performance (Bank 1)+](/t3Portal/stylegraphics/info.gif) ).

).

(2) Perform the Active Test, referring to DTC P0014 inspection procedure (VVT system for exhaust camshaft) (See page

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE (ENGINE CONTROL): SFI SYSTEM: P0014,P0015,P0024,P0025; Camshaft Position "B" - Timing Over-Advanced or System Performance (Bank 1)+](/t3Portal/stylegraphics/info.gif) ).

).

| NG |

|

|

|

9. |

READ VALUE USING TECHSTREAM (MAF) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Data List / MAF, Coolant Temp and Engine Speed.

(e) Read MAF with the engine speed at 3000 rpm.

Standard:

|

Techstream Display |

Condition |

Specified Condition |

|---|---|---|

|

MAF |

Shift lever position: N (Neutral) A/C: Off Engine Speed: 3000 rpm |

Between 11 gm/sec. and 16 gm/sec |

| OK |

|

| NG |

|

|

10. |

REPAIR OR REPLACE PCV HOSE |

(a) Repair or replace the PCV valve or hose.

| NEXT |

|

|

11. |

REPAIR OR REPLACE INTAKE SYSTEM |

(a) Repair or replace the intake system.

HINT:

Perform "Inspection After Repair" after repairing or replacing the intake system (See page

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE (ENGINE CONTROL): SFI SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif) ).

).

| NEXT |

|

|

12. |

REPLACE AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY |

(a) Replace the air cleaner filter element sub-assembly.

| NEXT |

|

|

13. |

CHECK AND REPAIR VVT SENSOR |

(a) Check and repair the VVT system.

HINT:

|

|

14. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P050B) |

NOTICE:

In this operation, the engine must be cold (approximately the same as the engine coolant temperature recorded in the freeze frame data).

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(e) Turn the ignition switch off and wait for at least 30 seconds.

(f) Turn the ignition switch to ON and turn the Techstream on.

(g) Enter the following menus: Powertrain / Engine / Data List / Coolant Temp.

(h) Check that the engine coolant temperature is between -10 and 50°C (14 and 122°F).

(i) Start the engine and warm it up until the engine coolant temperature is the same as the engine coolant temperature in the freeze frame data.

(j) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(k) Enter the following menus: Powertrain / Engine / Utility / All Readiness.

(l) Input the DTC: P050B.

(m) Check the DTC judgment result.

Result

|

Result |

Proceed to |

|---|---|

|

NORMAL (DTC is not output) |

A |

|

ABNORMAL (DTC P050B is output) |

B |

| A |

|

END |

| B |

|

|

15. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P050B) |

NOTICE:

In this operation, the engine must be cold (approximately the same as the engine coolant temperature recorded in the freeze frame data).

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(e) Turn the ignition switch off and wait for at least 30 seconds.

(f) Turn the ignition switch to ON and turn the Techstream on.

(g) Enter the following menus: Powertrain / Engine / Data List / Coolant Temp.

(h) Check that the engine coolant temperature is between -10 and 50°C (14 and 122°F).

(i) Start the engine and warm it up until the engine coolant temperature is the same as the engine coolant temperature in the freeze frame data.

(j) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(k) Enter the following menus: Powertrain / Engine / Utility / All Readiness.

(l) Input the DTC: P050B.

(m) Check the DTC judgment result.

Result

|

Result |

Proceed to |

|---|---|

|

NORMAL (DTC is not output) |

A |

|

ABNORMAL (DTC P050B is output) |

B |

| A |

|

|

|

16. |

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER CONNECTOR CONNECTION) |

(a) Check the connection and terminal contact pressure of connectors and wire harnesses between the mass air flow meter and ECM (See page

![2016 - 2020 MY Sienna [12/2015 - ]; INTRODUCTION: HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS: ELECTRONIC CIRCUIT INSPECTION PROCEDURE](/t3Portal/stylegraphics/info.gif) ).

).

HINT:

Repair any problems.

|

|

17. |

CHECK WHETHER DTC OUTPUT RECURS (DTC P050B) |

NOTICE:

In this operation, the engine must be cold (approximately the same as the engine coolant temperature recorded in the freeze frame data).

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(e) Turn the ignition switch off and wait for at least 30 seconds.

(f) Turn the ignition switch to ON and turn the Techstream on.

(g) Enter the following menus: Powertrain / Engine / Data List / Coolant Temp.

(h) Check that the engine coolant temperature is between -10 and 50°C (14 and 122°F).

(i) Start the engine and warm it up until the engine coolant temperature is the same as the engine coolant temperature in the freeze frame data.

(j) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(k) Enter the following menus: Powertrain / Engine / Utility / All Readiness.

(l) Input the DTC: P050B.

(m) Check the DTC judgment result.

Result

|

Result |

Proceed to |

|---|---|

|

ABNORMAL (DTC P050B is output) |

A |

|

NORMAL (DTC is not output) |

B |

| B |

|

END |

|

|

18. |

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM) |

(a) Disconnect the B4 mass air flow meter connector.

(b) Disconnect the B1 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

B4-5 (VG) - B1-74 (VG) |

Always |

Below 1 Ω |

|

B4-4 (E2G) - B1-75 (E2G) |

Always |

Below 1 Ω |

|

B4-5 (VG) or B1-74 (VG) - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

19. |

REPLACE MASS AIR FLOW METER |

(a) Replace the mass air flow meter (See page

![2016 MY Sienna [12/2015 - 08/2016]; 2GR-FE (ENGINE CONTROL): MASS AIR FLOW METER: REMOVAL](/t3Portal/stylegraphics/info.gif) ).

).

HINT:

|

|

20. |

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

NOTICE:

In this operation, the engine must be cold (approximately the same as the engine coolant temperature recorded in the freeze frame data).

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(e) Turn the ignition switch off and wait for at least 30 seconds.

(f) Turn the ignition switch to ON and turn the Techstream on.

(g) Enter the following menus: Powertrain / Engine / Data List / Coolant Temp.

(h) Check that the engine coolant temperature is between -10 and 50°C (14 and 122°F).

(i) Start the engine and warm it up until the engine coolant temperature is the same as the engine coolant temperature in the freeze frame data.

(j) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(k) Enter the following menus: Powertrain / Engine / Utility / All Readiness.

(l) Input the DTC: P050B.

(m) Check the DTC judgment result.

Result

|

Result |

Proceed to |

|---|---|

|

NORMAL (DTC is not output) |

A |

|

ABNORMAL (DTC P050B is output) |

B |

| A |

|

END |

| B |

|

|

|

|